-

-

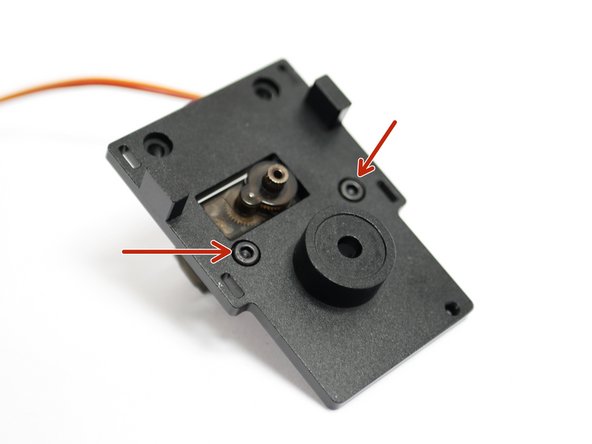

Use two M2.5 x 6mm bolts to fix the servo onto the backplate.

-

Make sure that the servo shaft is centrally aligned with the backplate.

-

-

-

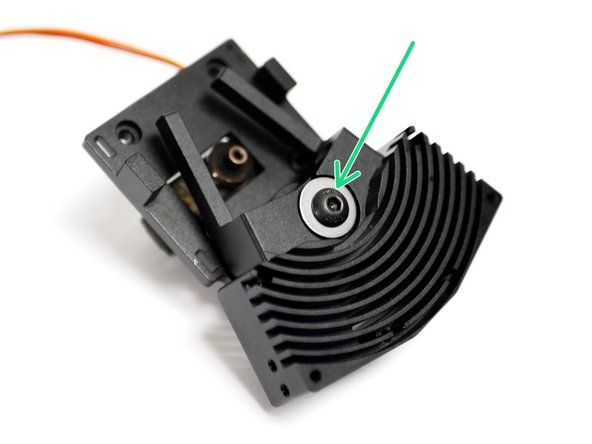

Insert an M5 x 20mm bolt with a needle bearing and shim.

-

M5 x 20mm Bolt

-

Thrust Bearing

-

Shim

-

On the other side of the heatsink slide on another thrust bearing.

-

-

-

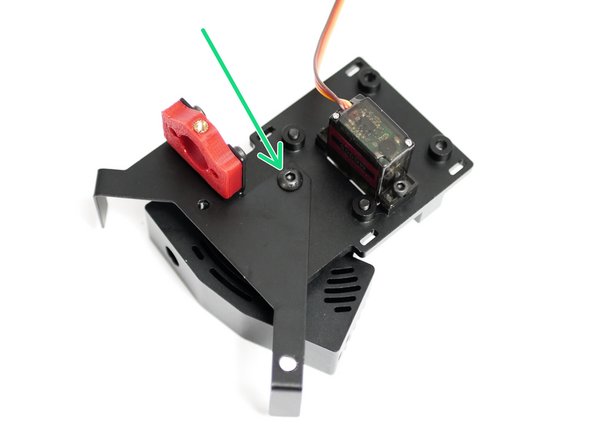

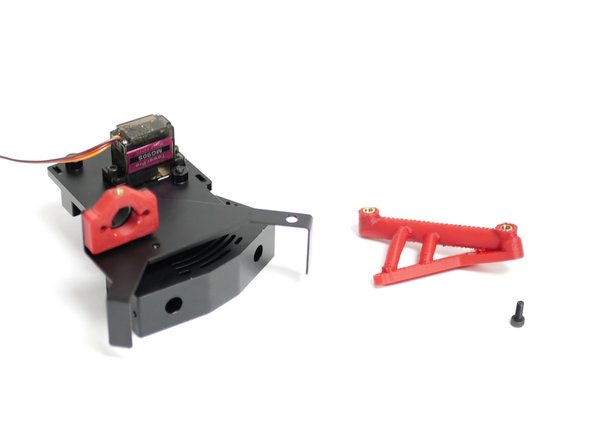

Begin by preparing the backplate with two M3 x 8mm bolts as shown.

-

Drop an M5 nut into the back of the Backplate.

-

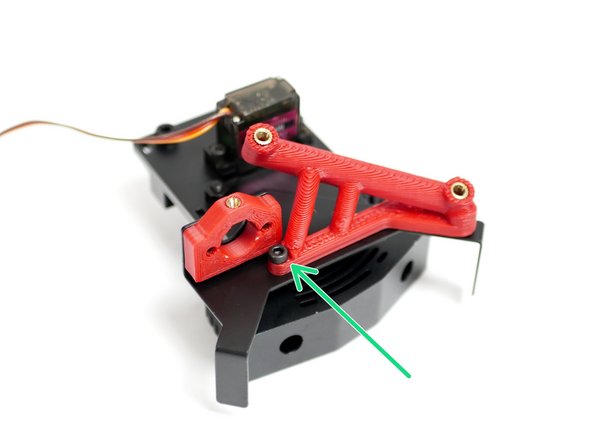

Fix the assembly together, making sure that there is no play in the switching motion.

-

The bolt should be tightened down enough to allow the heatsink to rock, but there shouldn't be any play along the axis of rotation or on the plane of contact.

-

-

-

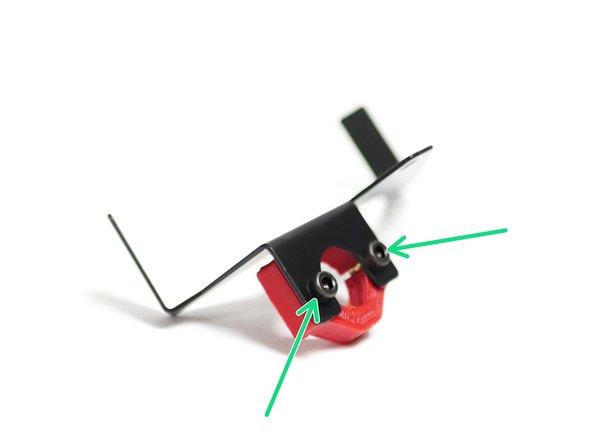

Fix the Probe mount onto the metal fan and probe mount as shown.

-

M3 x 8mm Cap

-

-

-

Fix the Probe and Fan Mount onto the backplate with just one M4 x 6mm bolt.

-

-

-

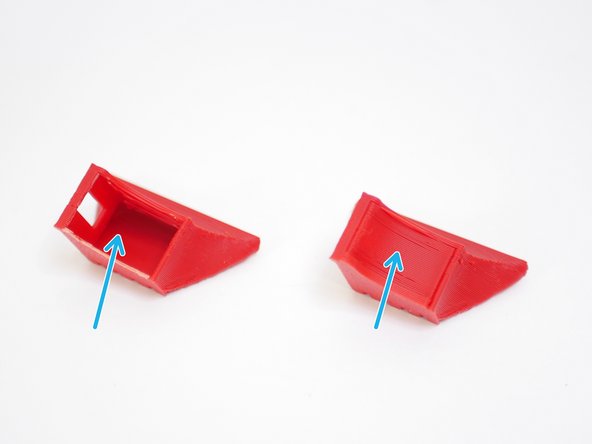

Fix the Angled Fan Mount to the Backplate with one M3 x 8mm bolt.

-

Remove the support material from under the angled fan mount before mounting.

-

On the front of the assembly, use an M4 x 6mm bolt to secure the angled fan mount.

-

-

-

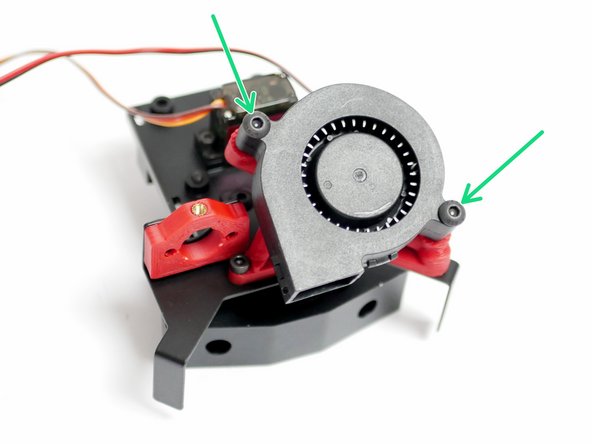

Secure the part cooling fan to the mount with two M4 x 20mm bolts.

-

-

-

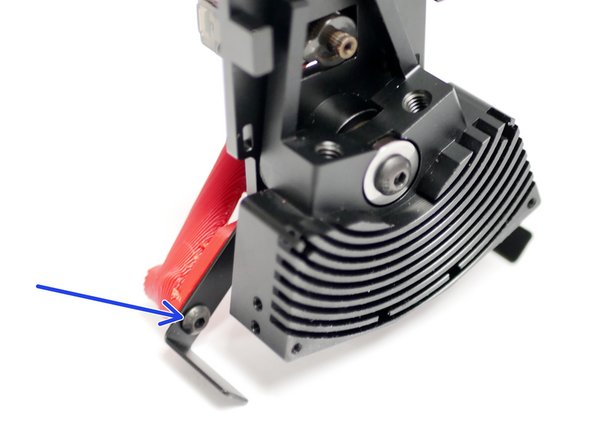

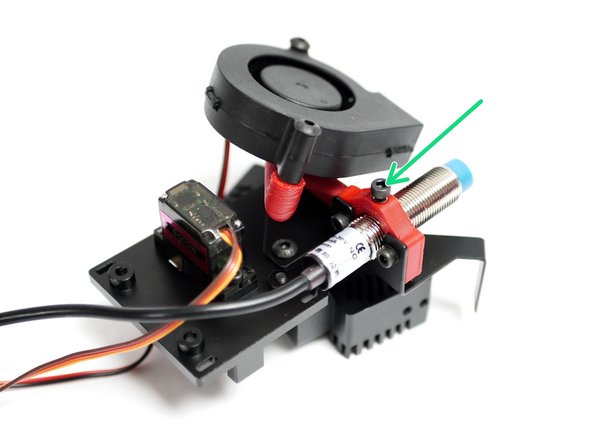

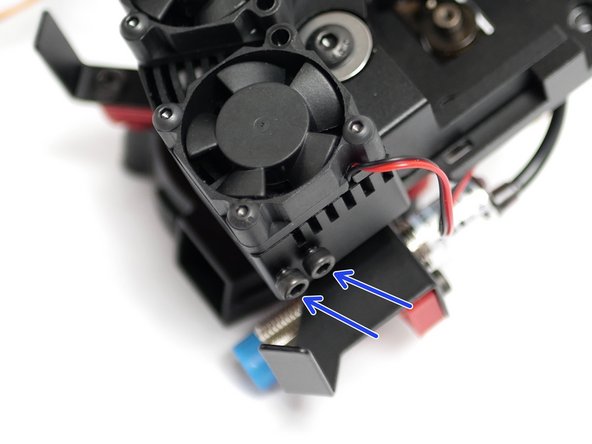

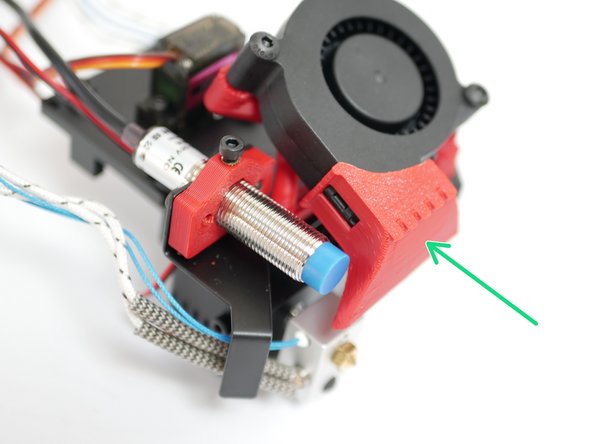

Insert the probe here and lightly secure it with an M3 x 8mm bolt.

-

We'll be adjusting the height of the probe later.

-

-

-

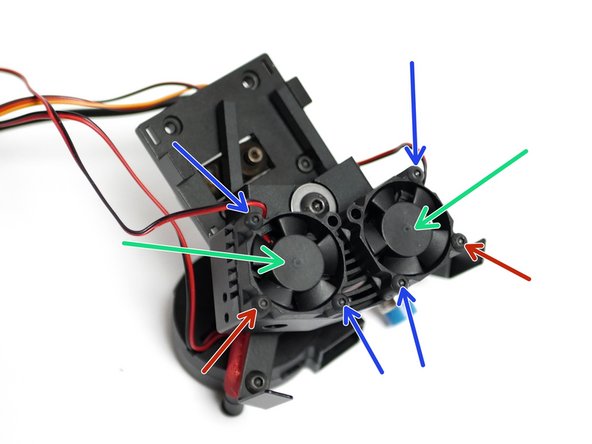

Fix the two 30mm fans to the heatsink:

-

M3 x 12mm bolt

-

M3 x 20mm bolt

-

-

-

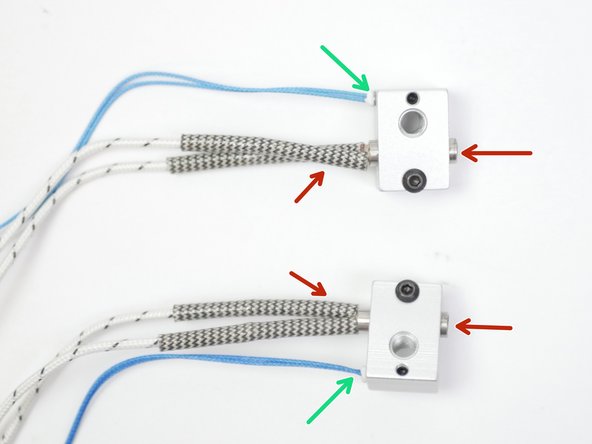

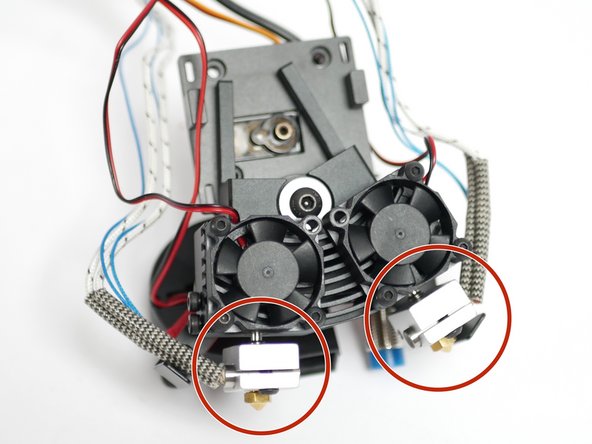

Take the two heater blocks and fix into them the two heater cartridges as shown.

-

Fix two thermistors to the blocks. We've shown two high temp. thermistors being installed here, but it is identical for the low temp thermistors too.

-

Make sure to match the orientation as shown in the photos. The two assemblies should mirror each other.

-

-

-

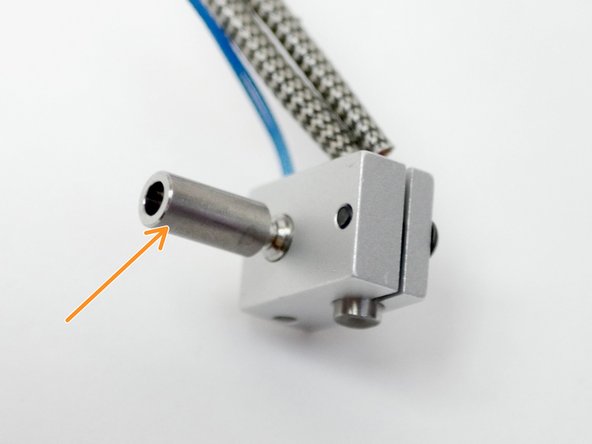

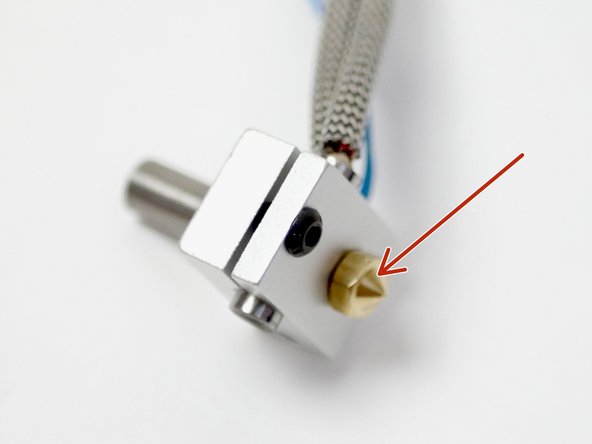

Fix onto both the heater blocks, the heatbreak.

-

and the nozzle.

-

Make sure that the nozzle is tight against the heatbreak, but leave a slight gap between the nozzle and heater block when tightening. The nozzle will need to be tightened again when hot.

-

-

-

Prepare the heatsink by inserting two M3 x 12mm bolts onto each side.

-

Take the two heater block assemblies from the previous step and push them into the heatsink.

-

With the heater block assemblies pushed in all the way, tighten the bolts to secure them in place.

-

Note the orientation in the image. The heater side of the block should be facing forward.

-

-

-

Break the support material away from the fan shroud.

-

Clip the fan shroud onto the blower fan as shown.

-

-

-

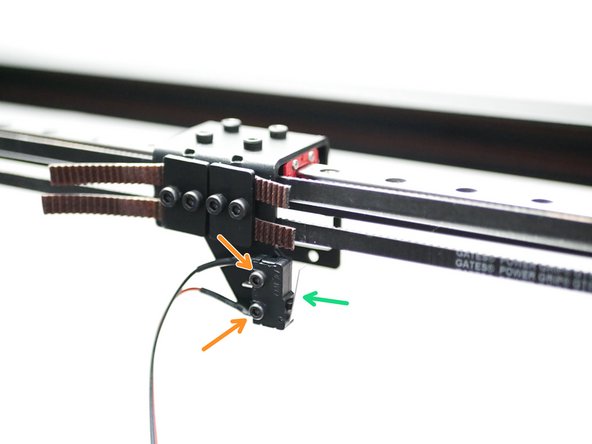

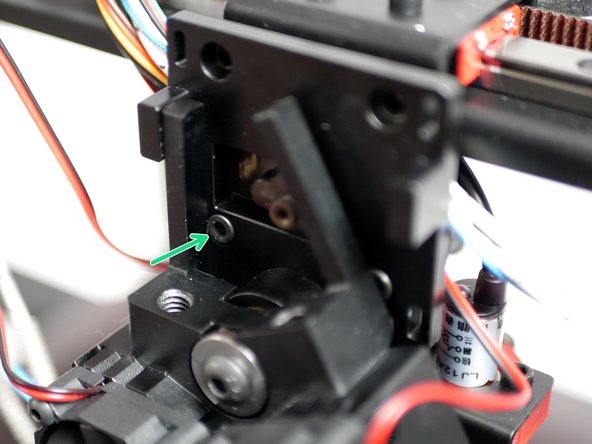

Install the X-Endstop as shown.

-

Note that the X-Endstop is the one with the longer 2M cable.

-

M2.5 x 12mm Bolt

-

M2.5 Nyloc Nut

-

-

-

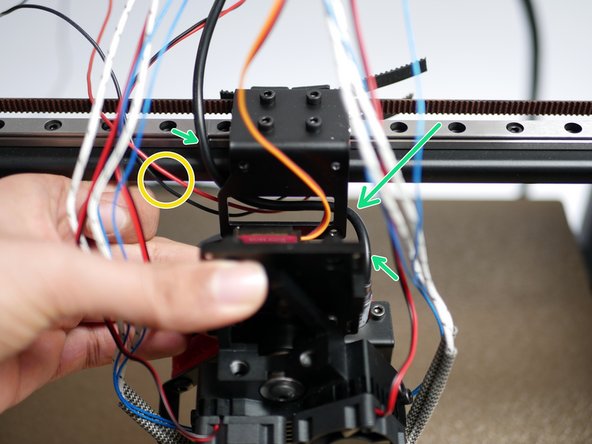

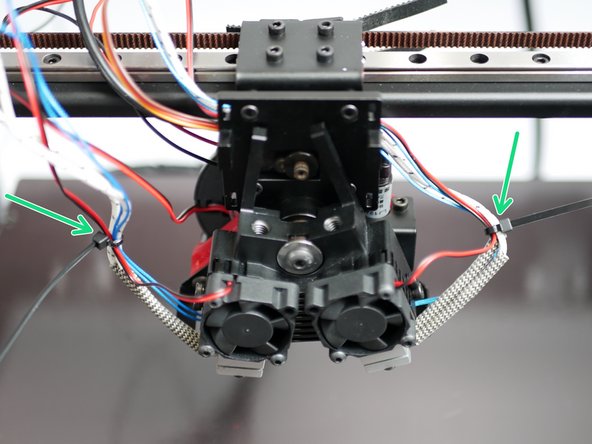

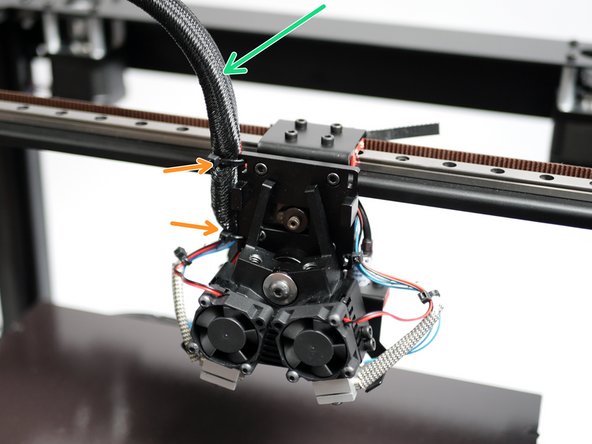

Lay the DSH assembly onto the platform and arrange the cables as shown

-

Left Hotend and blower fan cables

-

Servo and Probe cables

-

Right Hotend cables

-

-

-

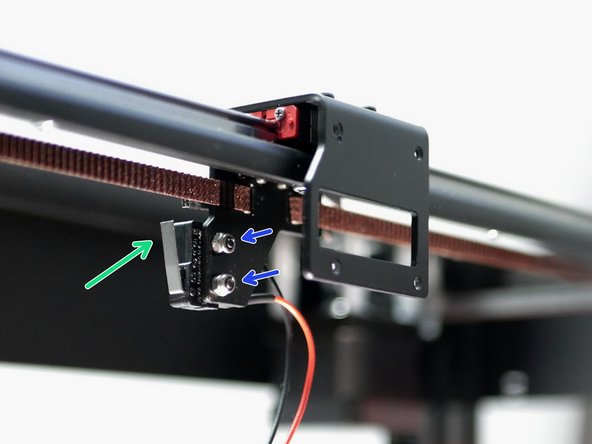

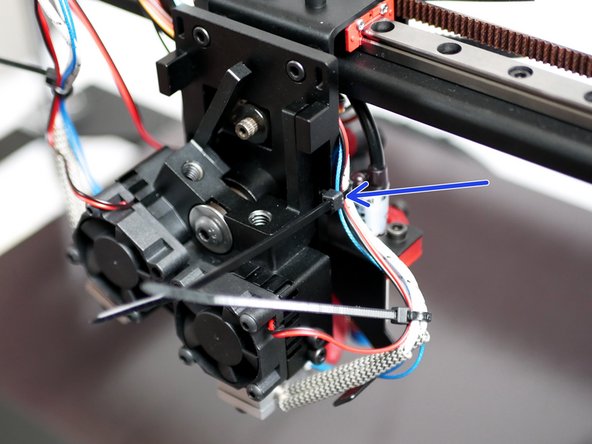

Bring the X-Endstop cable around to the front of the gantry.

-

Route the probe cable behind the tool carriage.

-

Push the servo into the hole in the tool carriage along with its cable.

-

Take the cables from the right hotend and place them over the servo.

-

-

-

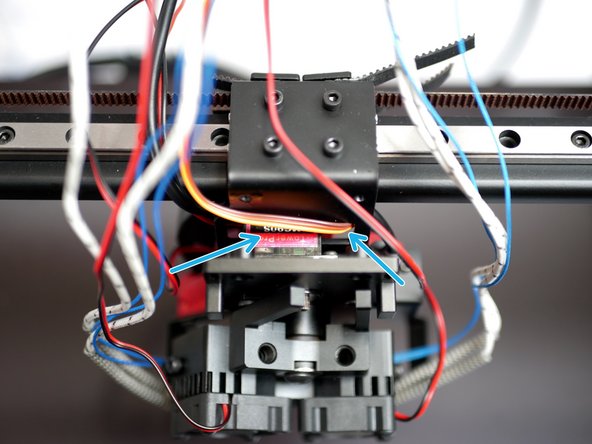

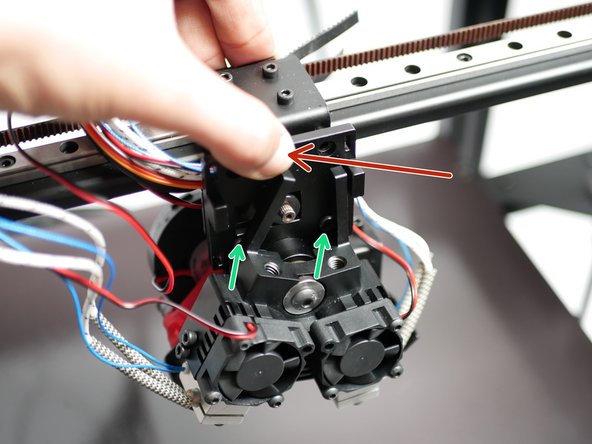

Press the DSH assembly onto the tool carriage, make sure that none of the cables are getting pinched.

-

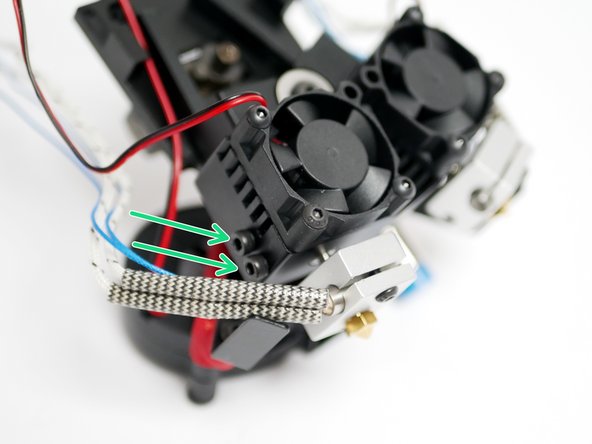

Tighten the two M3 x 8mm bolts. Do this in alternation in order to allow the hotend to rotate out of the way.

-

Finally, use two M3 x 8mm bolts to completely secure the DSH to the carraige.

-

-

-

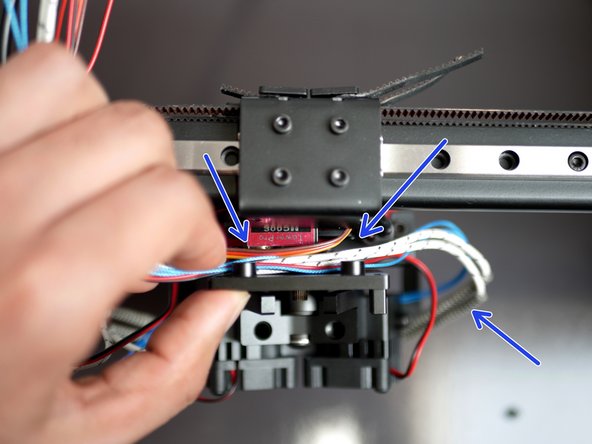

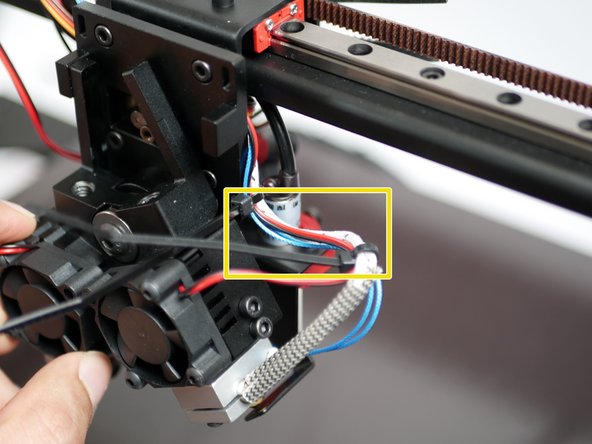

Cable tie together the heater, thermistor and 30mm fan cables from each hotend.

-

Cable tie the right hotends cables to the backplate also.

-

Ensure that when parked the highlighted part of the right hotends cables are horizontal.

-

-

-

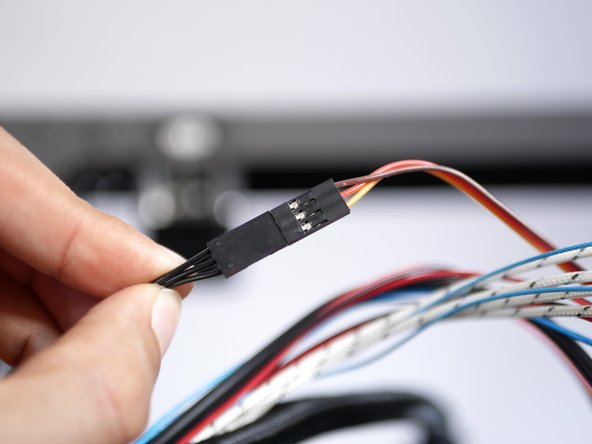

Connect the servo cable to the servo extension cable as shown.

-

-

-

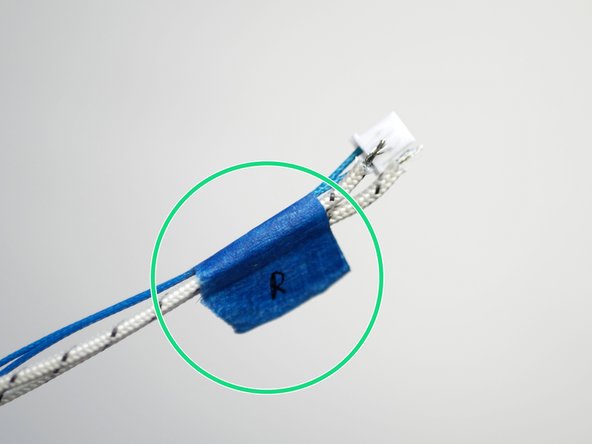

Use tape to mark, in this case, the right hotend heater cables and thermistor.

-

-

-

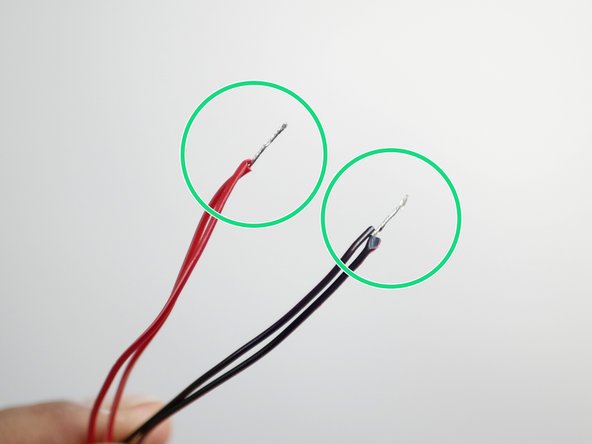

Take the hotend heatsink fan cables and use side cutters, scissors, or wire strippers to remove the connectors from their ends.

-

Strip away the outer sleeving to expose some of the wire.

-

Wrap the black and red wires together as shown.

-

-

-

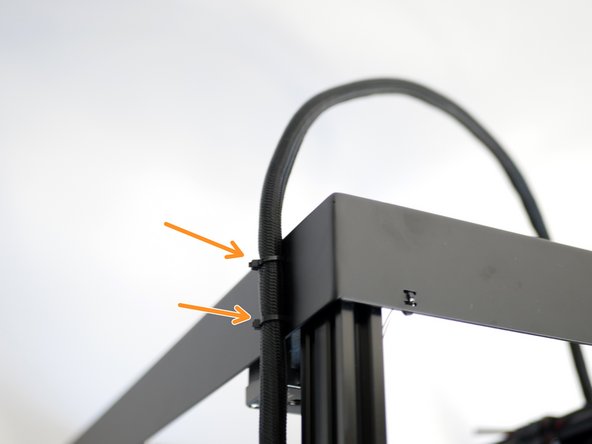

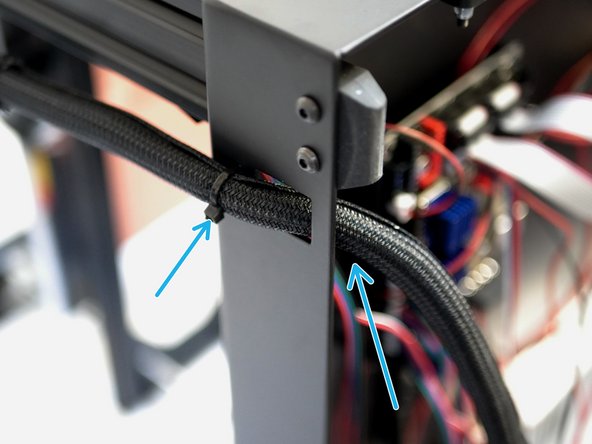

Wrap the cables with the braided cable sleeving.

-

Cable tie the cables to the backplate as shown.

-

-

-

Push the tool carraige to the bottom left of the print area.

-

Use cable ties to secure the loom to the rear of the top panel.

-

Feed the loom of cables into the base and secure with a cable tie.

-

-

-

Adjust the ooze shields by bending the metal sleds until they are able to make contact with the tips of both nozzles.

-

-

-

The Hotend covers simply slide in place over the heater blocks.

-