-

-

-

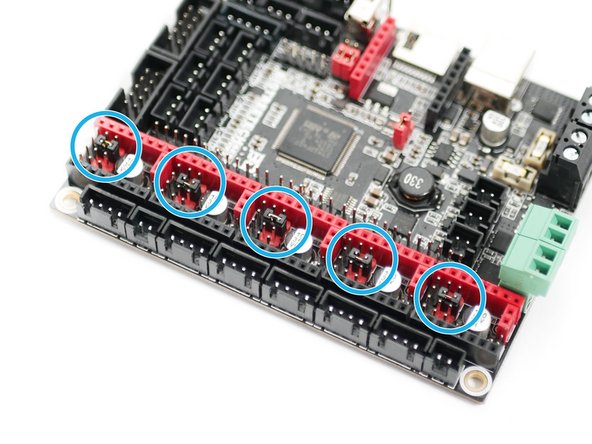

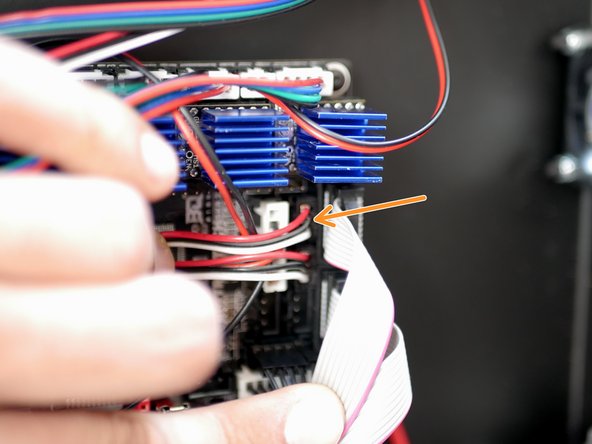

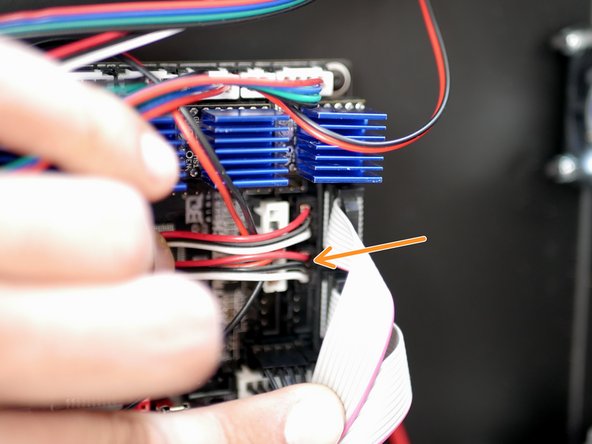

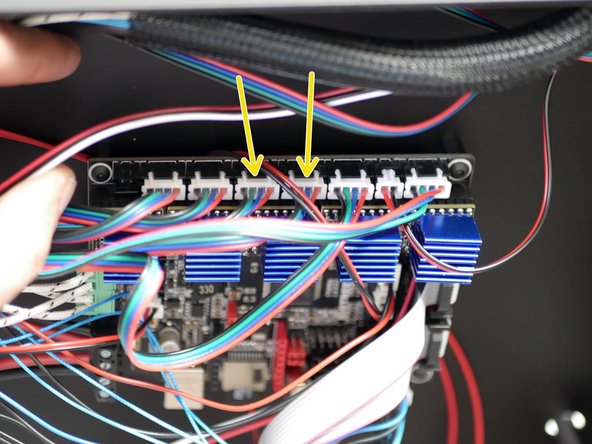

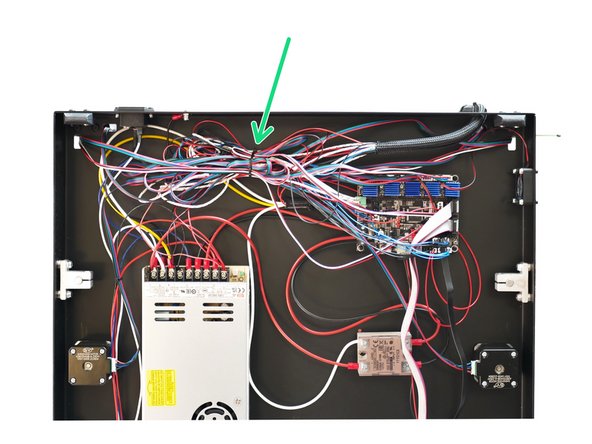

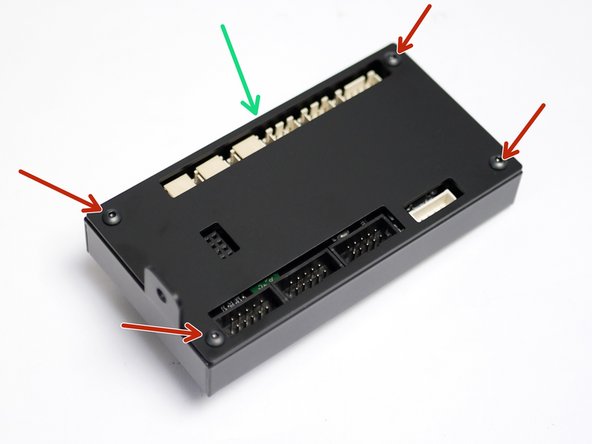

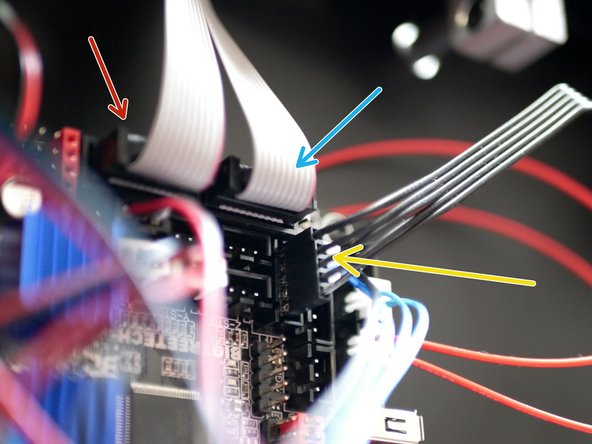

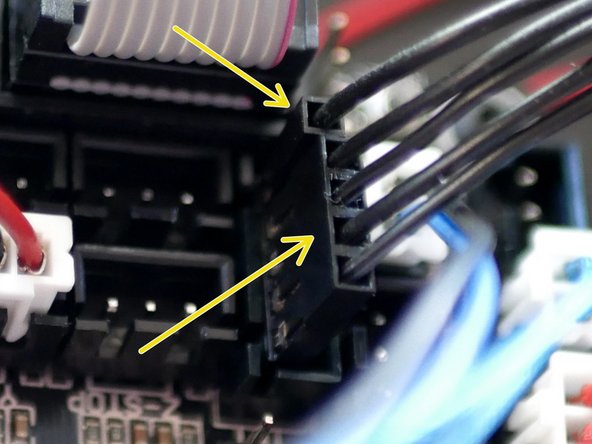

Make sure the jumpers under the steppers are positioned as shown.

-

You will need to pull the other jumpers out, so you have just one connected at each stepper location, as shown.

-

-

-

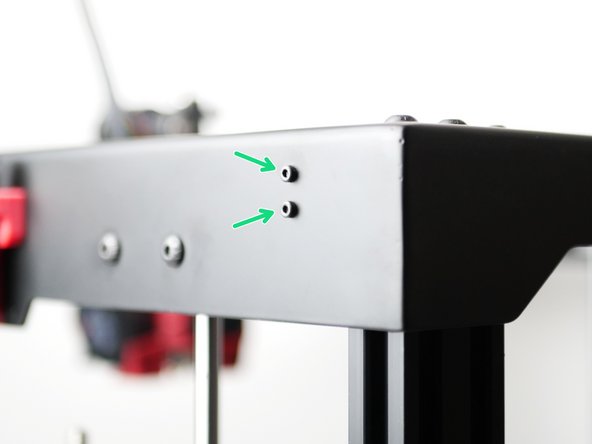

Fix the Y-Endstop to the top panel.

-

M2.5 x 12mm

-

M2.5 Nyloc

-

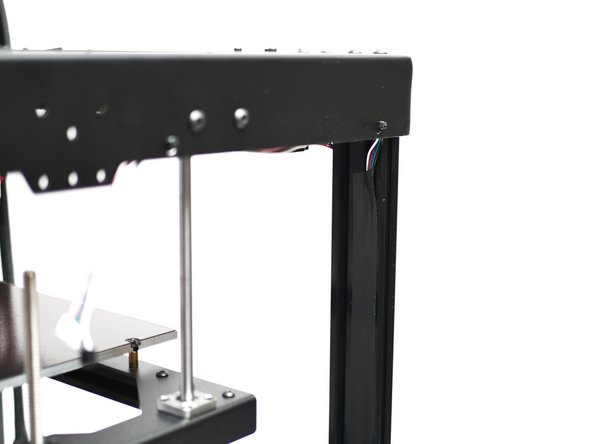

Route the cable down the 2040 extrusion.

-

Optional - Use electrical tape to better secure and hide the cable.

-

-

-

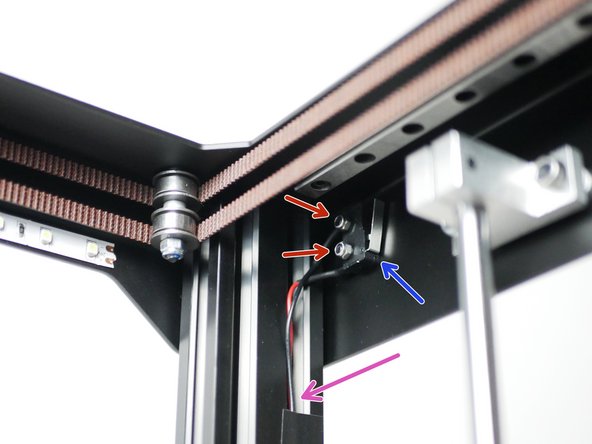

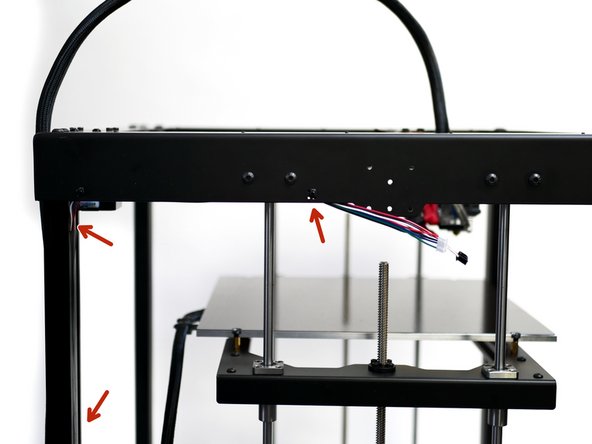

Take the filament sensor and motor cables together and fix with a cable tie to the top panel.

-

Route the cables down the 2040 extrusion as shown. Use electrical tape to cover the cables.

-

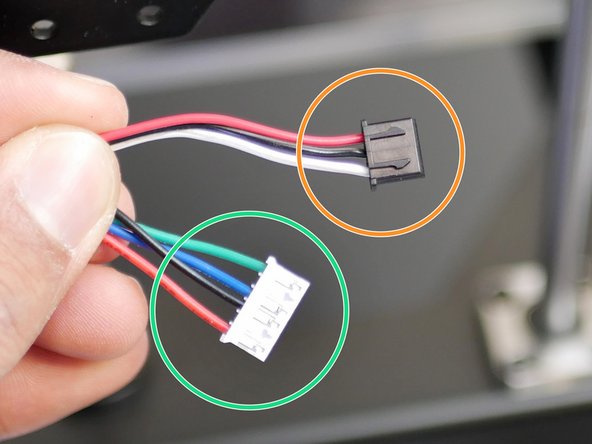

Make sure that the sides of the cable that are fixed to the top panel are those that are shown in the photo.

-

Motor cable

-

Filament sensor cable

-

-

-

Repeat the previous step, but this time on the right side of the printer.

-

-

-

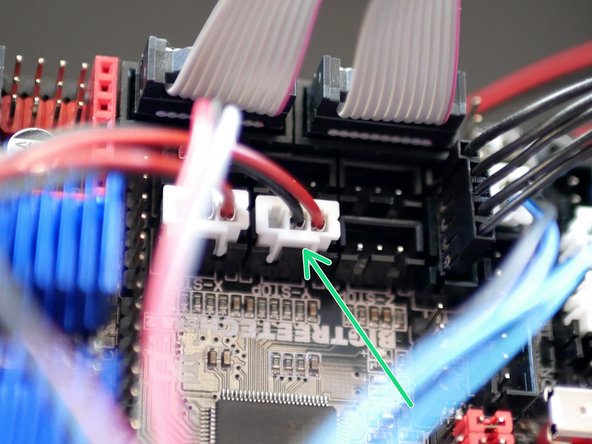

Connect the left side extruder motor cable to the control board.

-

Connect the left side extruder filament sensor to the control board.

-

-

-

Connect the right sides motor cable to the control board.

-

Connect the right sides filament sensor to the control board.

-

-

-

Connect a motor cable to the X/Y Motors and route them down the side of the 2040 Extrusion.

-

Use electrical tape to hide and secure in place.

-

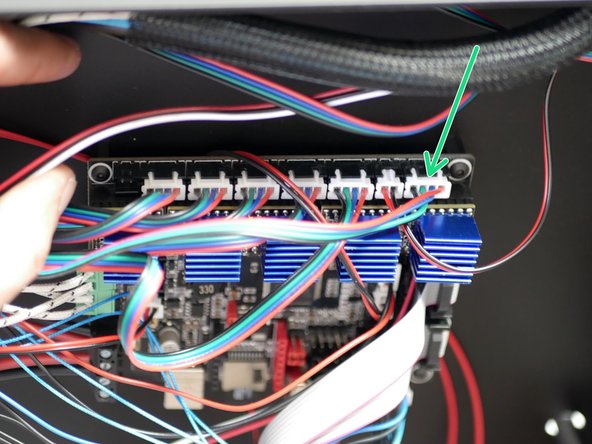

Connect the motor cables to the control board.

-

Left Motor

-

Right Motor

-

-

-

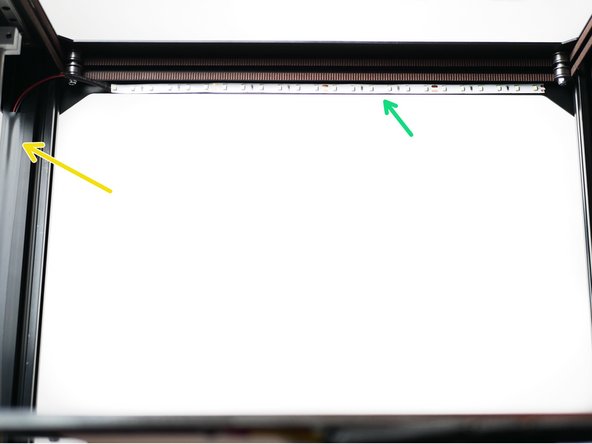

Stick the LED strip light to the inside front of the top panel.

-

Route the cable down the front right side. Again, use electrical tape to hide and hold the cable in place.

-

Wire the LED's directly to the power supply.

-

Red to positive

-

Black to negative

-

-

-

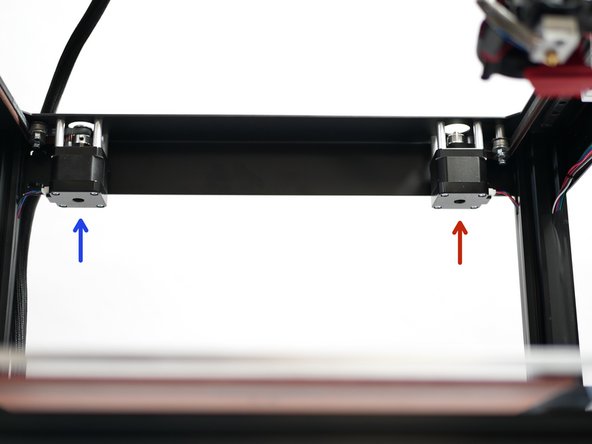

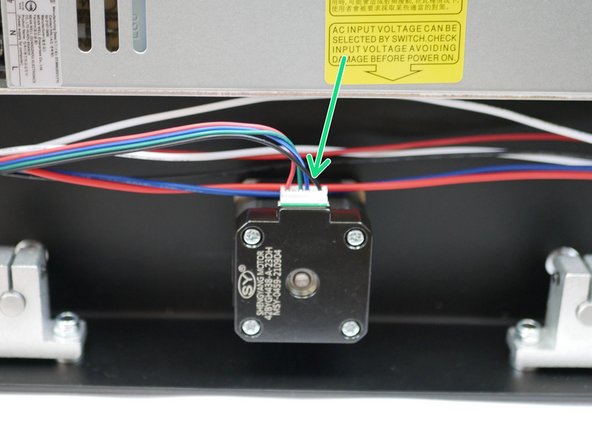

Connect the remaining two motor cables to the two z-axis motors.

-

Connect the other side to the control board.

-

-

-

Connect the X-Endstop to the control board.

-

This is the endstop cable from the tool carriage wiring loom.

-

-

-

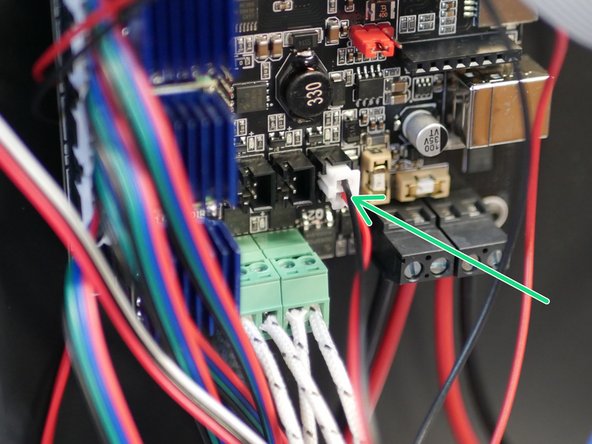

Take the left sides hotend heater and attach the cables to this connector.

-

Take the right sides hotend heater and attach the cables to this connector.

-

The connector can actually be pulled out of the board to make connecting the cables easier.

-

You will need a small flat head screw driver for this step.

-

-

-

Connect the two hotend thermistors to the control board.

-

Left Hotend Thermistor

-

Right Hotend Thermistor

-

-

-

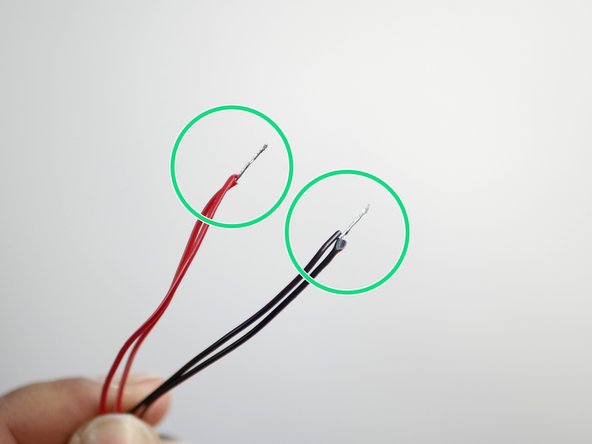

The two 30mm fans on the DSH heatsink are connected directly to the power supply.

-

Use scissors or side cutters to remove the two connectors and expose some wire.

-

Twist the two red and black cables together as shown.

-

Connect them directly to the power supply.

-

Red to positive.

-

Black to negative.

-

-

-

Connect the brown cable from the probe directly to a positive terminal on the power supply.

-

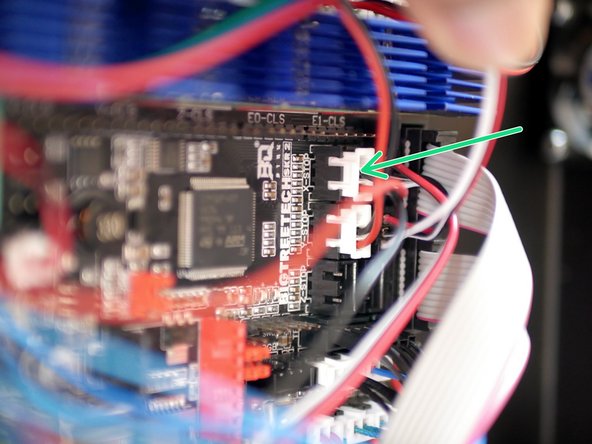

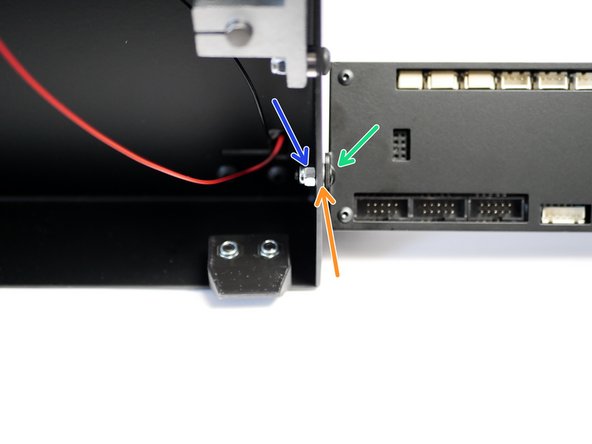

Connect the black and blue cable from the probe to the control board in the position shown.

-

-

-

Connect the servo to the control board as shown.

-

This is the servo extension cable.

-

-

-

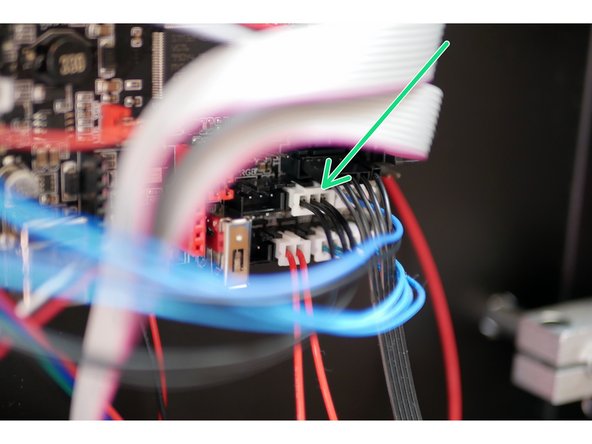

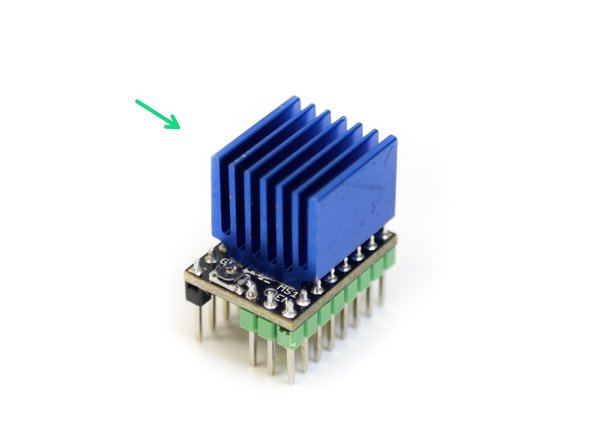

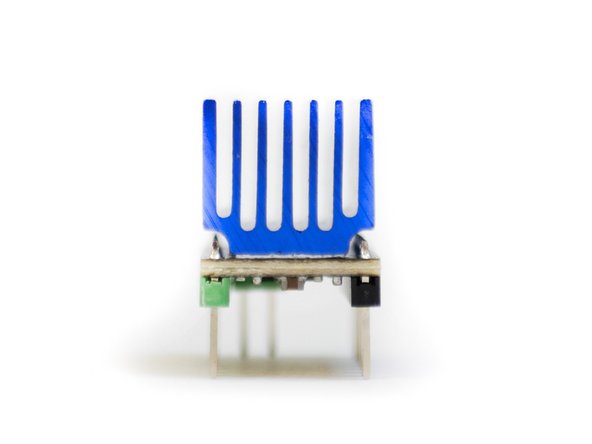

Before beginning, make sure that you have earthed yourself (by touching a large metal object) to avoid the chances of static damage.

-

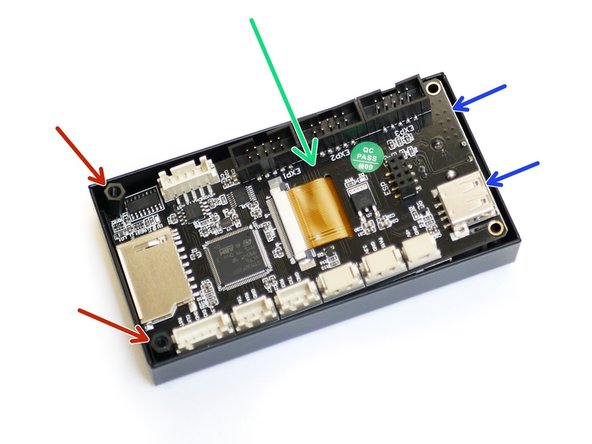

Prepare the five TMC2209 stepper drivers by removing them from their packaging and securing onto them their heat sinks as shown in the first image.

-

Make sure the heatsink is not touching any of the pins.

-

Orient the fins of the heatsink as shown.

-

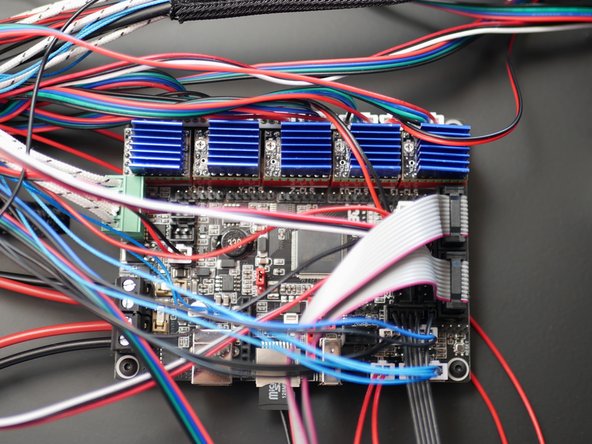

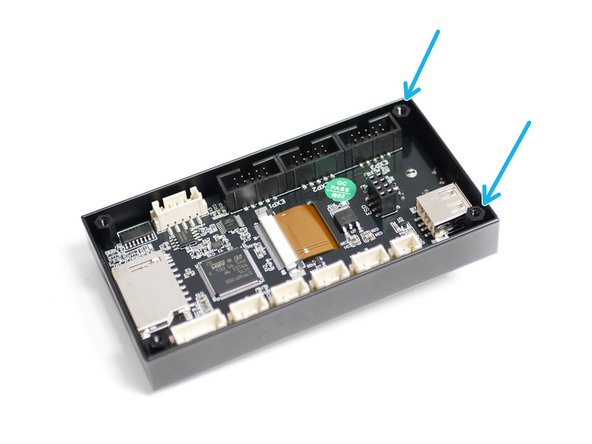

Mount all five of the TMC2209 Stepper Drivers to the control board as shown.

-

When installing, match the orientation of the drivers as shown, the green side of the stepper should go onto the red side of the mounts on the board.

-

Installing a stepper driver the wrong way round will destroy it.

-

-

-

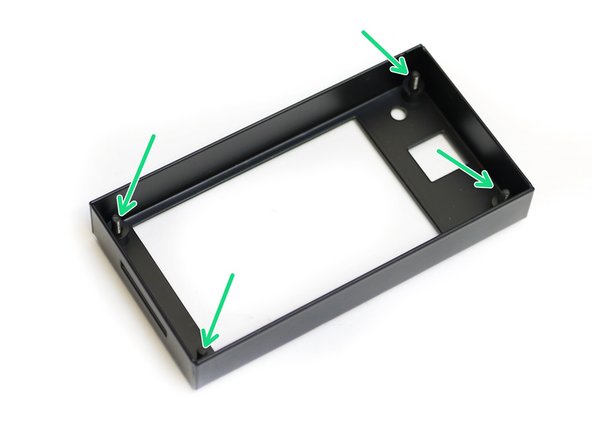

Begin by taking the touch screen case and insert four M3 x 12mm bolts through the four holes shown.

-

Place onto each of these bolts an M3 x 5mm spacer.

-

-

-

Begin by removing the black control know from the front side of the screen, it should simply pull off.

-

Align the touch screen with the case and drop it onto the four bolts.

-

When you drop the touch screen into the case, you'll find that the control knob side will stick up.

-

Thread on two M3 x 10mm threaded spacers to the two bolts on the left as shown.

-

-

-

With the left side secured, thread on two M3 x 10 threaded spacers to the remaining two bolts.

-

Hold the bolts from the underneath to prevent them from falling out.

-

-

-

Fix the mounting plate onto the back of the casing as shown.

-

M3 x 6mm bolt

-

Push the control knob back back on.

-

-

-

Attach the touch screen case assembly to the base of the printer as shown.

-

M4 x 10mm bolt

-

M4 Washer

-

M4 Nyloc

-

-

-

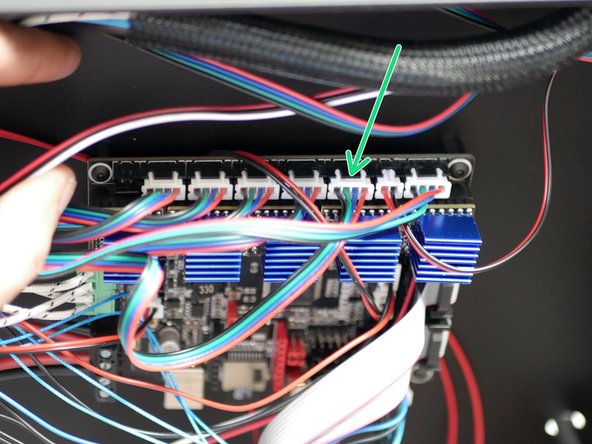

Black cable: This is for controlling the printer through the touch screen interface via serial.

-

The two white cables are for controlling the printer directly via marlin's interface through emulation mode.

-

EXP 1

-

EXP 2

-

Black cable - board side.

-

Note the orientation of the loose connector and the 4-pin connector, match as shown in the third image.

-

Cancel: I did not complete this guide.

3 other people completed this guide.