-

-

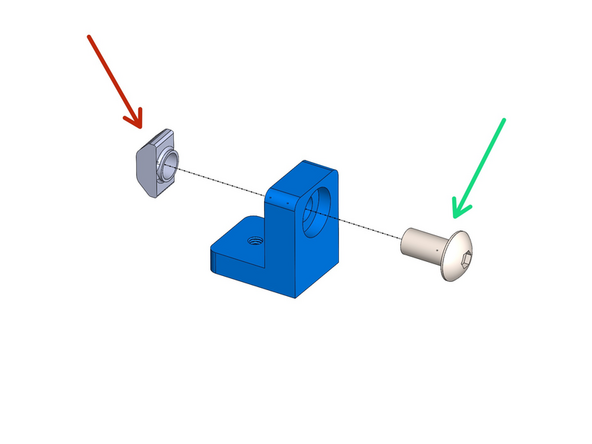

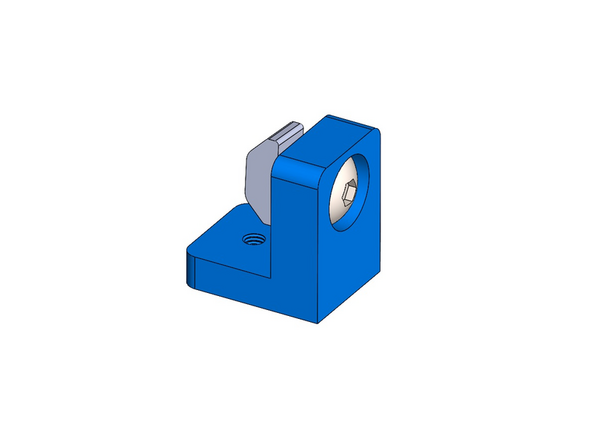

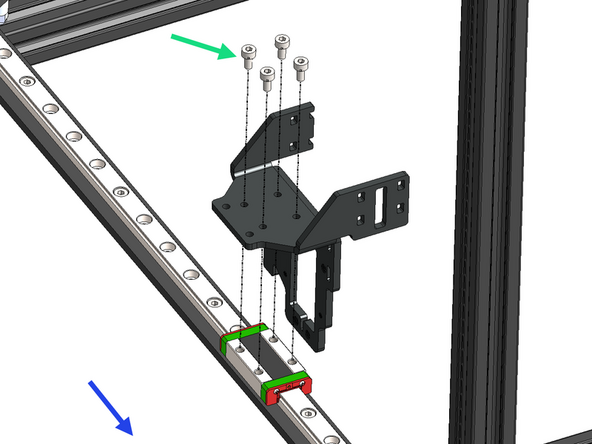

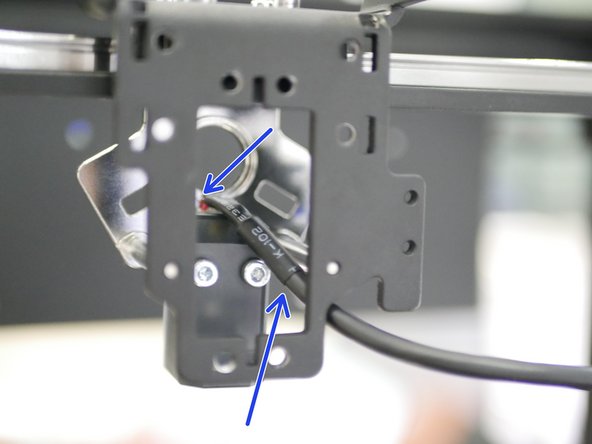

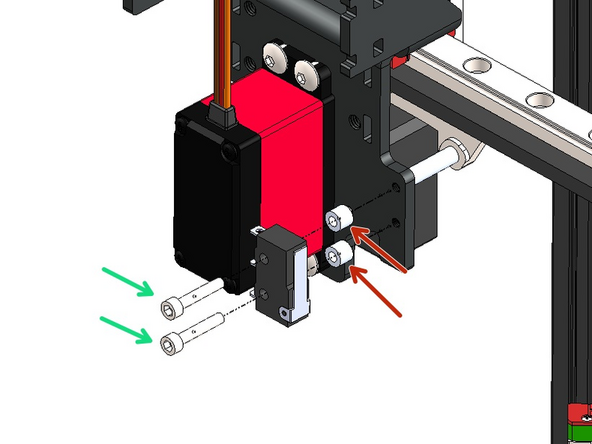

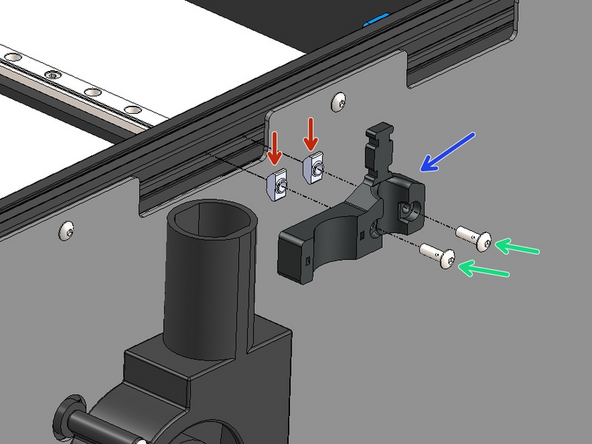

Build the X-Endstop assembly as shown:

-

X - Endstop

-

3D Printed X-Endstop Mount

-

If you find your endstop mount has oversized holes please print the updated part here if able to, or get in touch at info@makertech3d.com for a replacement.

-

M2.5 x 10mm Cap Head

-

M4 x 12mm Button Head

-

M4 T-Nut

-

-

-

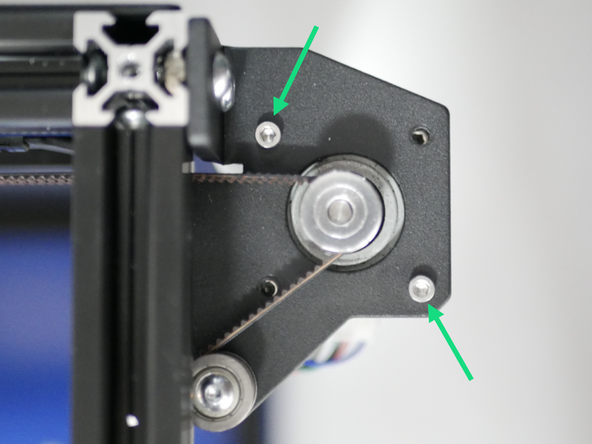

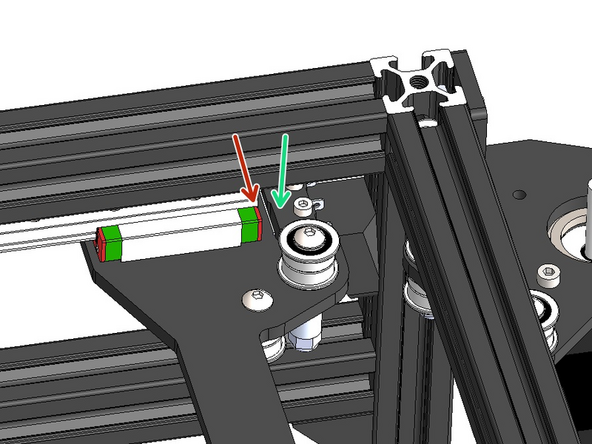

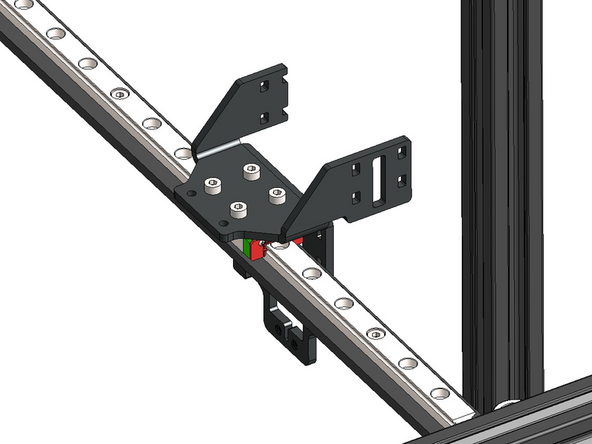

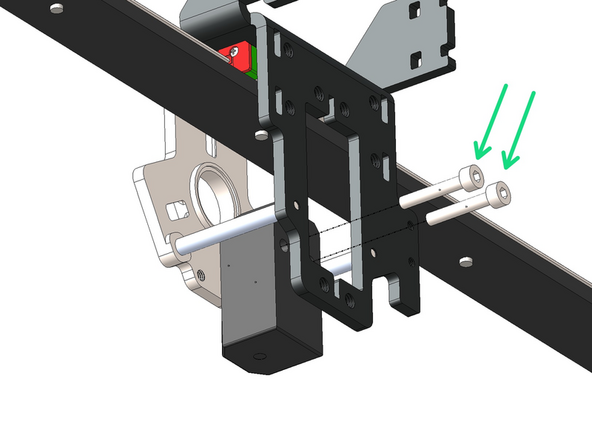

Mount the assembly to the inside rear right corner of the frame.

-

It should be fixed approximately 20mm from the top extrusion.

-

Note, the endstop is pre-wired.

-

-

-

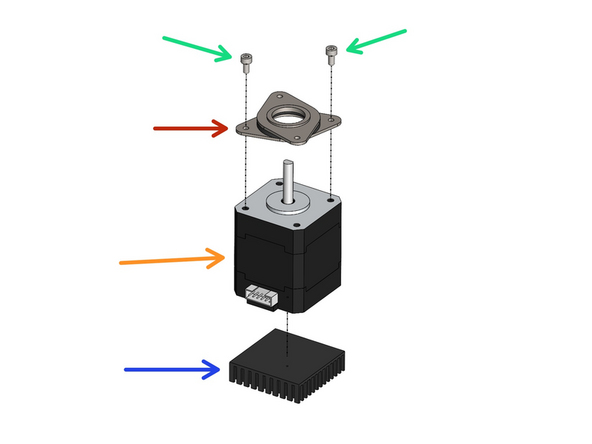

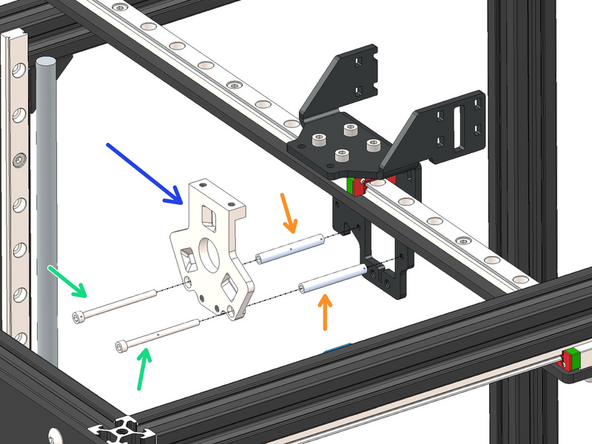

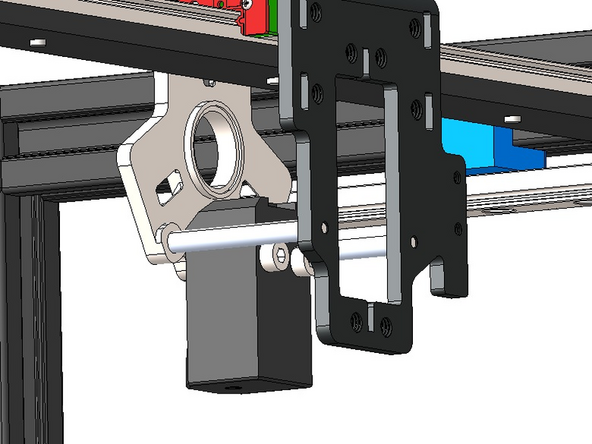

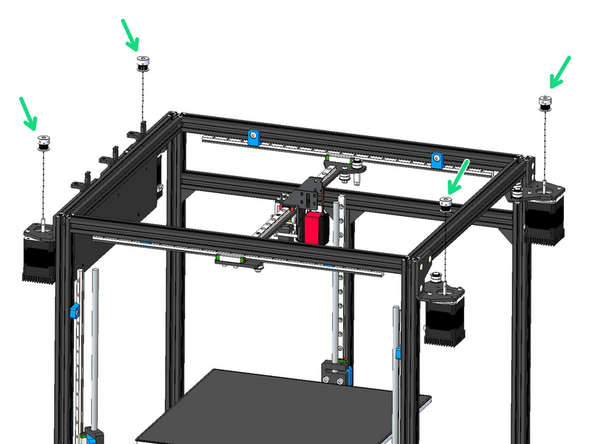

Fix onto the four LDO motors the vibration dampeners and heatsinks.

-

M3 x 6mm Cap Head

-

Vibration Dampener

-

LDO NEMA 17 Motor

-

Heatsink

-

Wipe down the base of the motor to remove any grease from the factory before sticking on the heatsink.

-

-

-

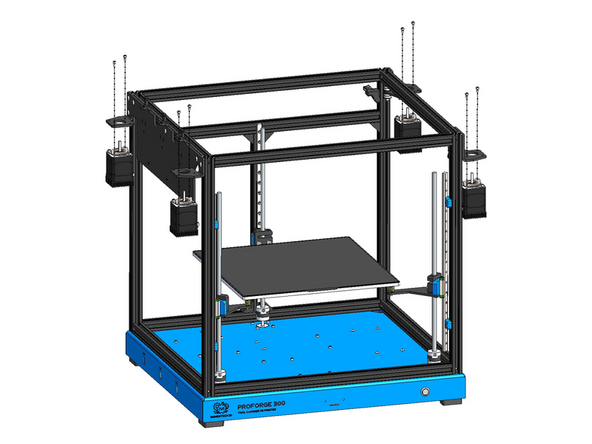

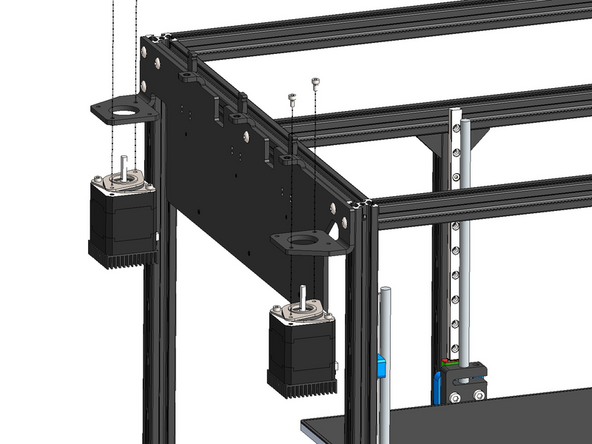

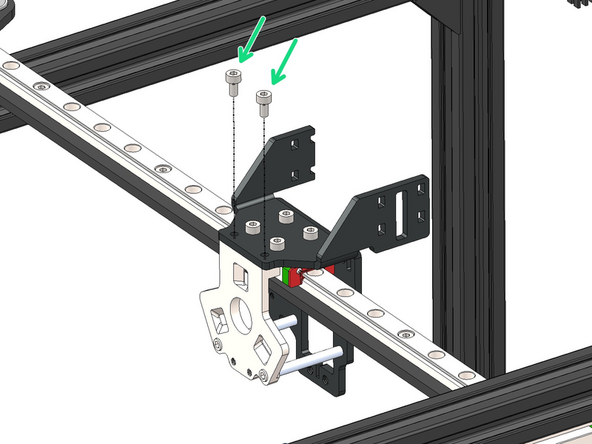

See the next step before installing the motors on the right side of the frame.

-

Mount the gantry motors as shown with M3 x 6mm Cap Head Bolts.

-

For easier installation of the enclosure panels we recommend pointing the motor connector ports away from the side of the printer.

-

-

-

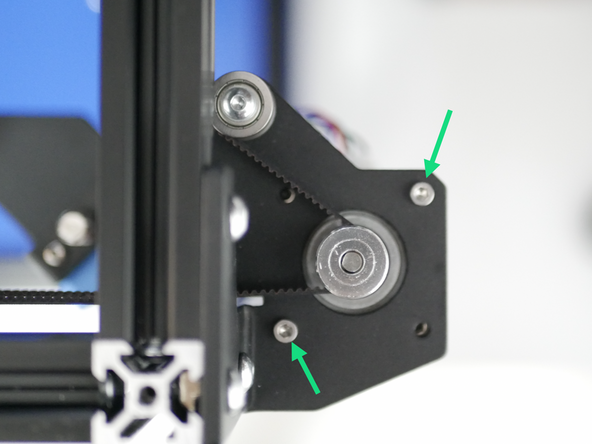

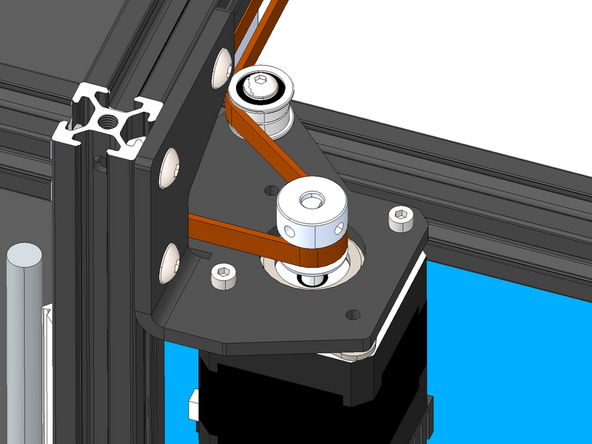

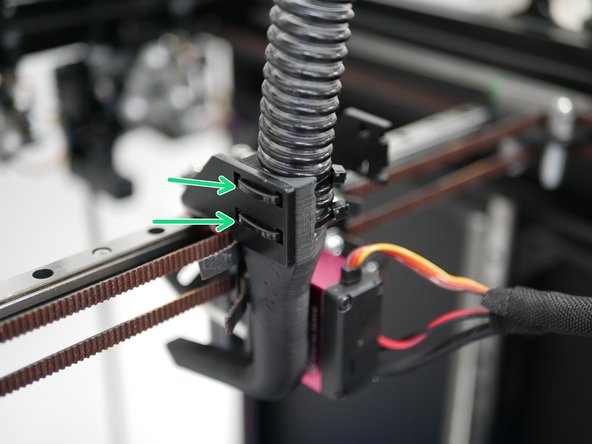

When installing the gantry motors onto the right side of the frame ensure that the bolts match as shown, if not they will rub against the belts later on.

-

-

-

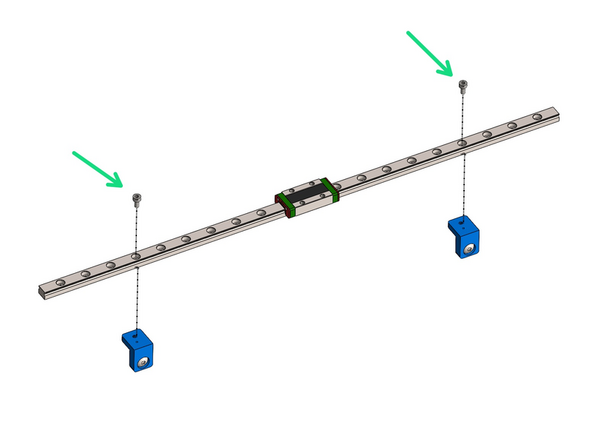

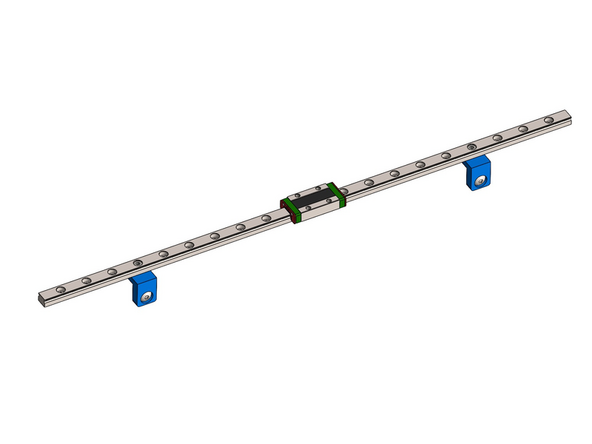

Keep the orange stoppers in place to prevent the carriage from falling off the rail.

-

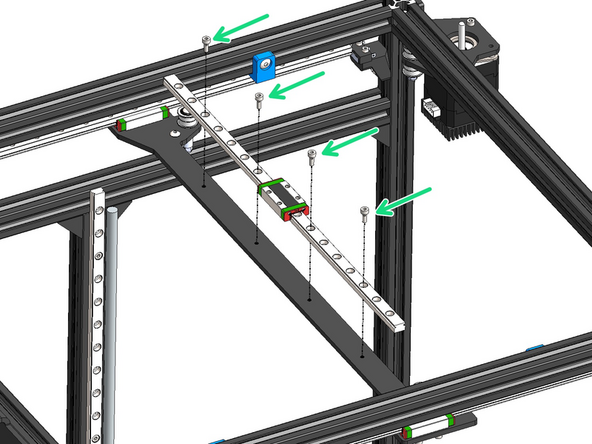

Fix the rail brackets onto the two 410mm long MGN9H rails.

-

Fix onto the fourth hole from the edge.

-

M3 x 6mm Cap Head

-

-

-

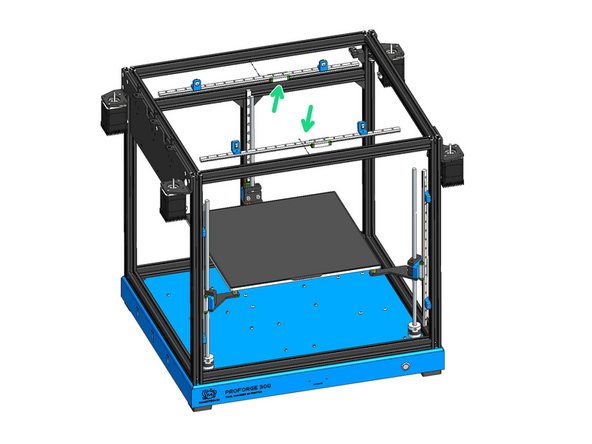

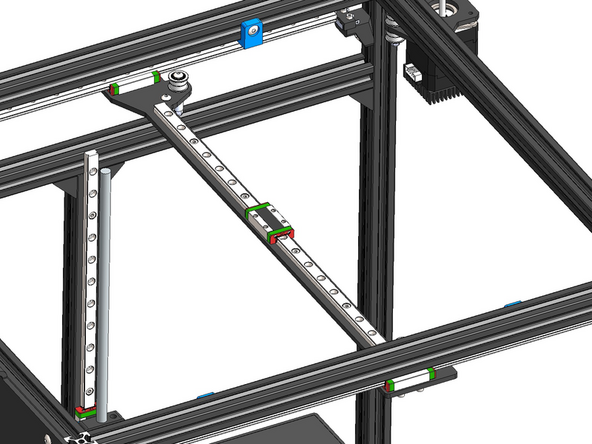

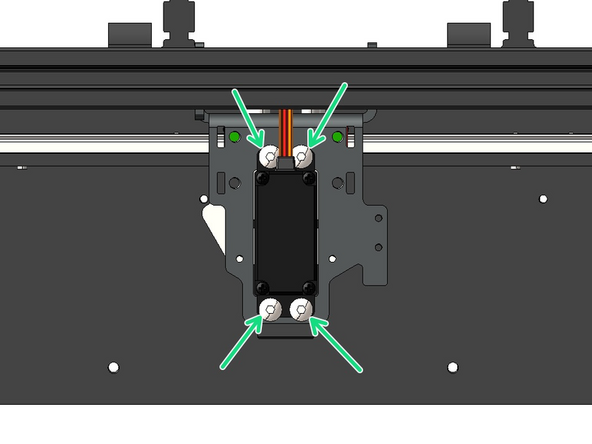

Mount the rails onto the inside of the top of the frame as shown.

-

There should be equal distance between the edges of the rails and the frame - around 30mm.

-

-

-

Install the gantry onto the rail carriages.

-

M3 x 8mm Cap Head

-

Fasten all bolts loosely before tightening, this will make installing easier.

-

-

-

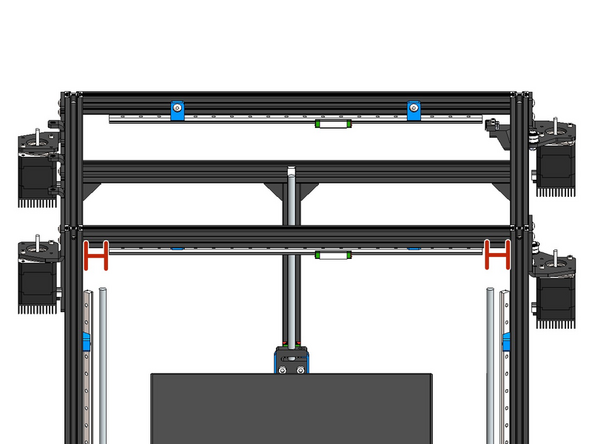

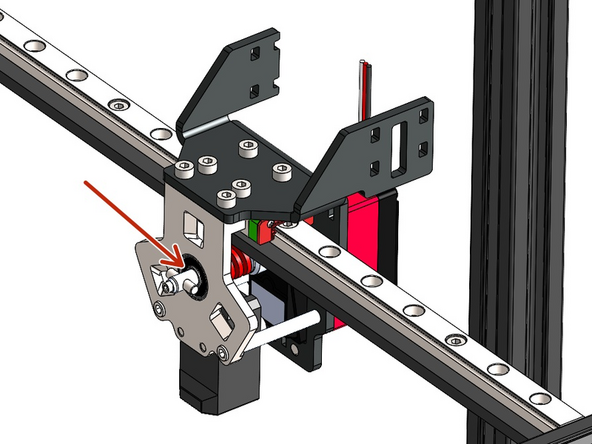

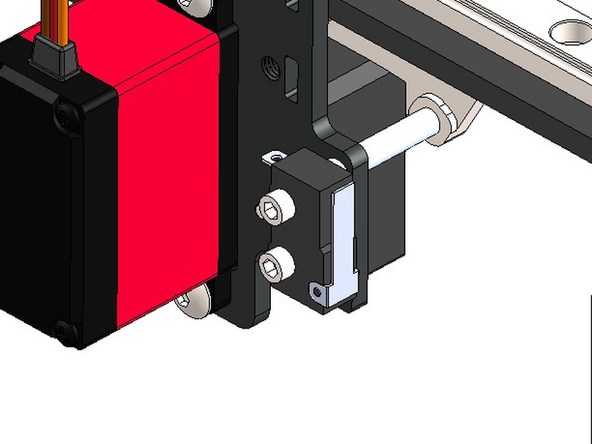

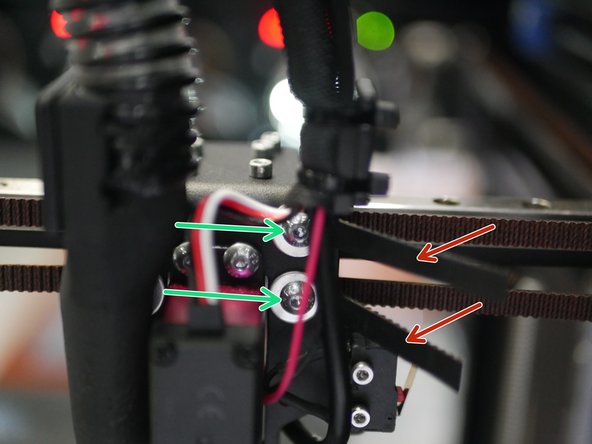

When the gantry is slid all the way to the right it should bump the endstop as shown.

-

Remove the orange stoppers to achieve this.

-

The rail carriage should be on the edge of the rail, but should not fall off.

-

Make adjustments to the rail and/or endstop mount accordingly if the above conditions are not met.

-

-

-

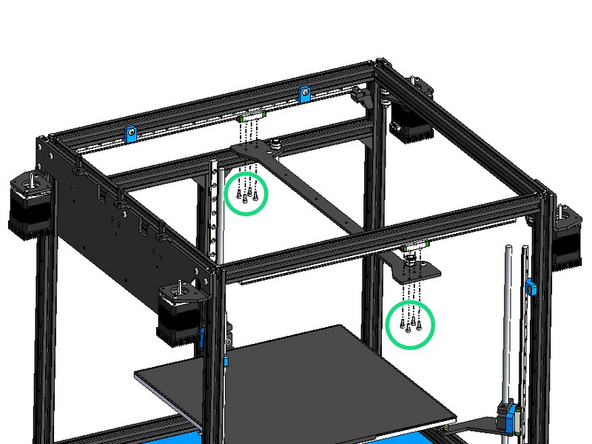

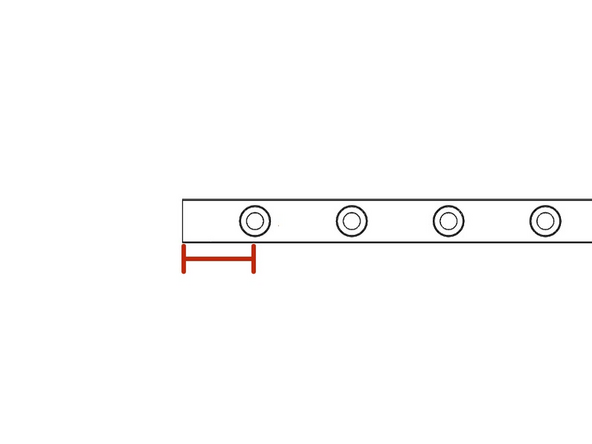

Mount the final 350mm MGN9H gantry rail onto the gantry.

-

M3 x 8mm Cap Head Bolt

-

The rail should have its mounting holes start 15mm from both ends.

-

-

-

Mount the tool carriage onto the gantry rail.

-

M3 x 6mm Cap Head Bolt

-

Front of machine.

-

-

-

Take extra care when tightening to not strip the aluminium threads on the carriage.

-

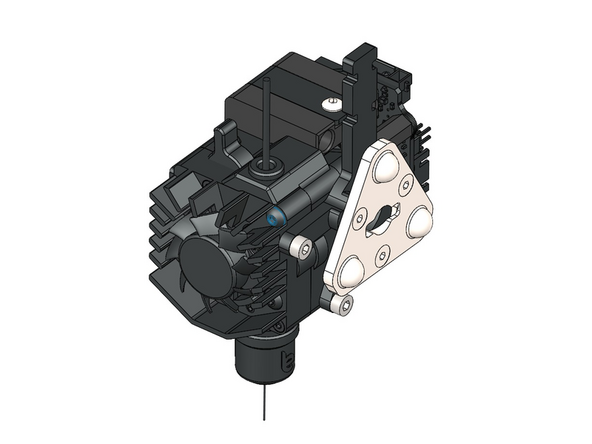

Fix the Master Plate onto the Tool Carriage.

-

Master Plate

-

M2.5 x 35mm Cap Head (Do not over tighten)

-

M2.5 x 30mm Spacer

-

-

-

If you end up stripping the threads in the previous step replace the bolt with a longer M2.5 x 40mm one and secure it with a nyloc nut.

-

If you aren't able to source the longer bolt and nut locally, please drop us an email at info@makertech3d.com and we'll ship a set out to you (ETA is around 5-7 working days).

-

-

-

Start by plugging the USB cable (from the Eddy box) into the top of the Eddy Probe. The cable should route under the spacer.

-

Fix the Probe to the Master Plate with two M3 x 18mm Cap Head Bolts.

-

-

-

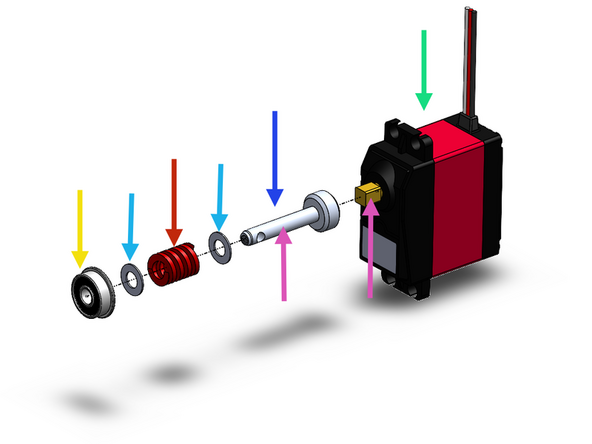

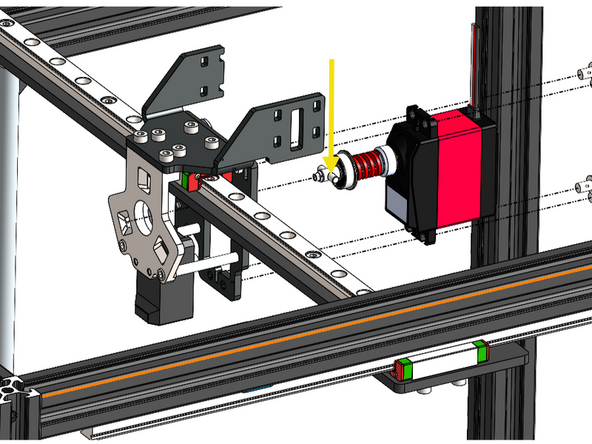

Assemble the Servo mechanism as shown.

-

Apply grease to both cam shafts.

-

Makertech Servo Motor

-

Servo Cam Shaft v2

-

M5 x 8 x 0.5mm Shim

-

Red Compression Spring

-

F605ZZ Bearing

-

-

-

Install the servo mechanism that you built in the previous step onto the Tool Carriage.

-

Cam pin installed in next step.

-

Feed it in from behind, ensuring the bearing sits inside the hole on the Master Plate.

-

M4 x 6mm Button Head Bolt

-

-

-

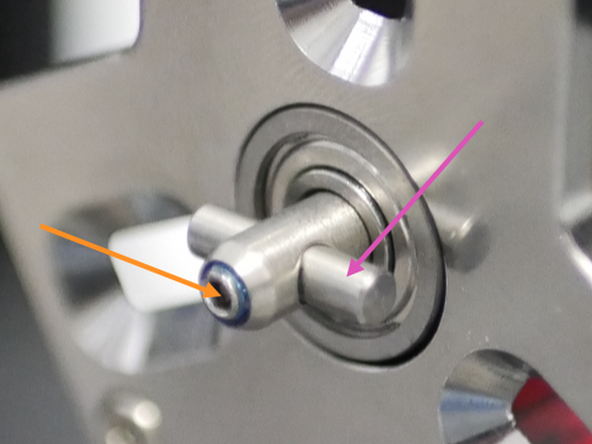

Install the cam pin with the grub screw pressing onto the flat face of the cam pin.

-

Use the included bottle of thread locker to ensure the grub screw does not come loose.

-

Cam Pin

-

M3 x 4mm Grub Screw

-

-

-

Fix the endstop to the Tool Carriage bracket as shown.

-

M2.5 x 14mm Cap Head Bolt

-

M2.5 x 4mm Spacer

-

-

-

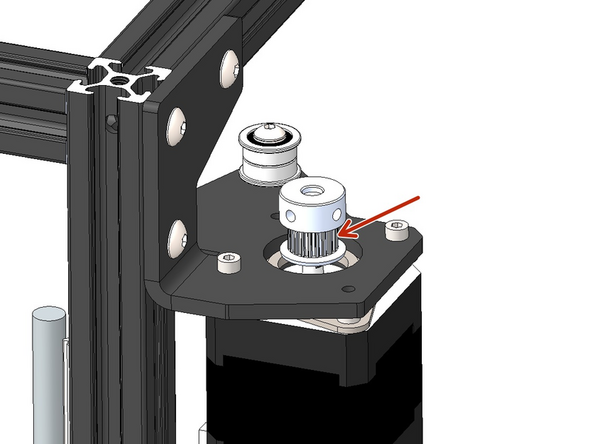

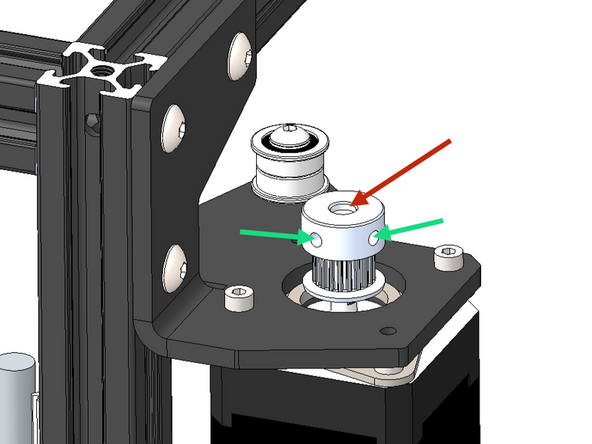

Drop pulleys onto each of the four motors.

-

Orientate so that the pulley teeth are facing downwards.

-

-

-

The ideal position for all of the pulleys should be approx 1-2mm above the end of the motor's shaft. You can align them later after installing the belts.

-

Ensure that one of the set screws is tightened against the flat of the motor shaft.

-

-

-

Take the 4m roll of GT2 belt and cut approximately it in half.

-

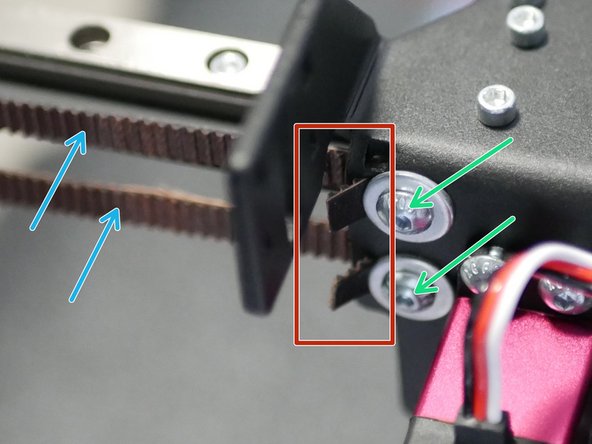

Take one end of each belt and feed it in through the slit on the back left side of the carriage bracket.

-

It needs to be fed in from the inside of the bracket - you might need to temporarily remove the bracket from the rail carriage to gain better access.

-

Ensure that the belts teeth are facing out.

-

Fix the belt in place with an M4 x 6mm button head bolt and M4 penny washer.

-

-

-

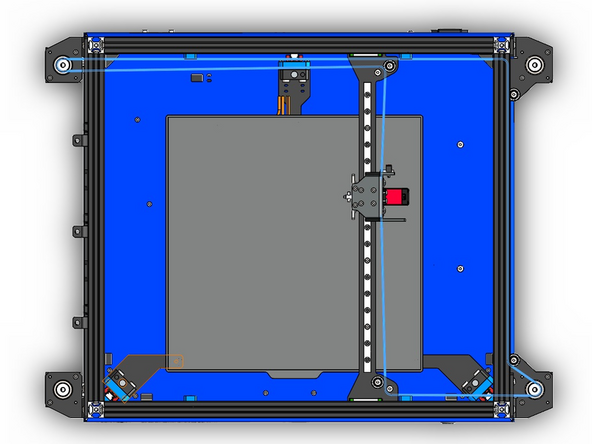

The bottom belt should follow this path around the idlers and motors.

-

Remember this is the bottom belt and should be wrapped around the bottom level idlers.

-

-

-

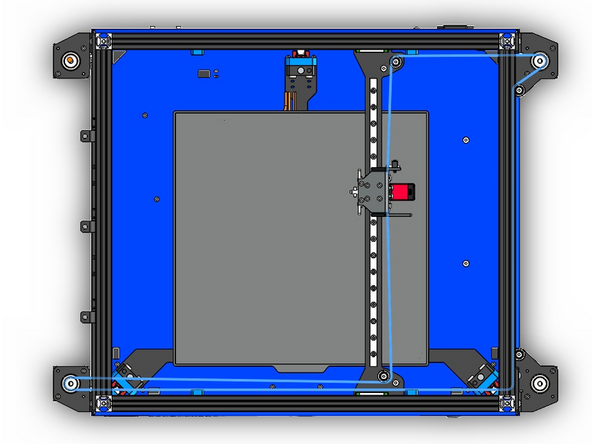

The top belt should follow this path around the idlers and motors.

-

Remember this is the top belt and should be wrapped around the top level idlers.

-

-

-

Adjust these bolts so you are able to pull the belts but also hold the tension without letting the belts slip back.

-

Pull the belts tight until there isn't any slack.

-

Next adjust the tension in the belts individually until the gantry sits straight. Use the left side of the frame as a reference.

-

Avoid over tensioning as this can result in greater vibrations and put unnecessary strain on the motor shafts.

-

Trim any excess, leaving approx. an inch free for any future adjustments.

-

-

-

With the belts tensioned manually move the tool carriage around to ensure that motion is smooth and that the belts are not catching on anything.

-

-

-

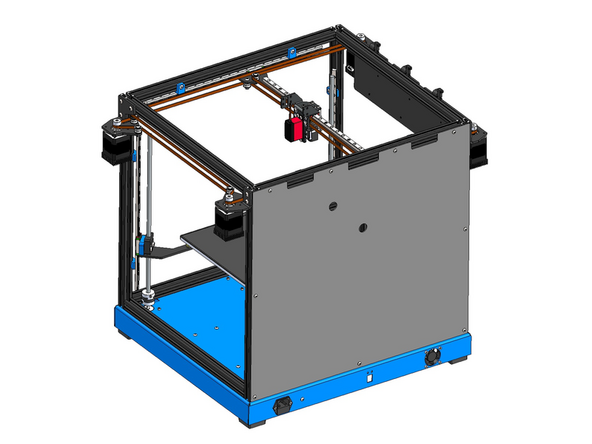

If you have the enclosure upgrade we recommend installing the rear panel now.

-

Rear Enclosure Panel (Glossy side out)

-

M4 x 8mm Button Head Bolt

-

M4 T-Nut

-

-

-

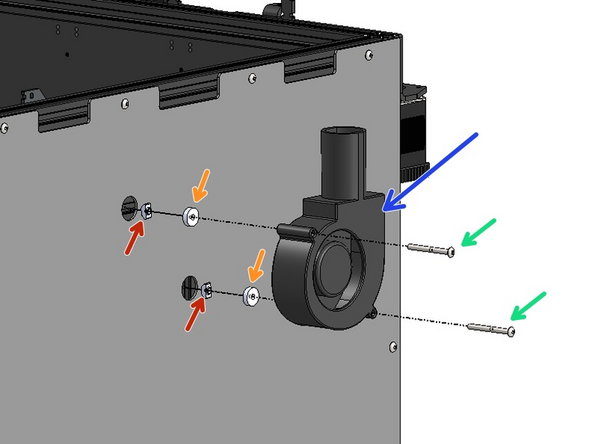

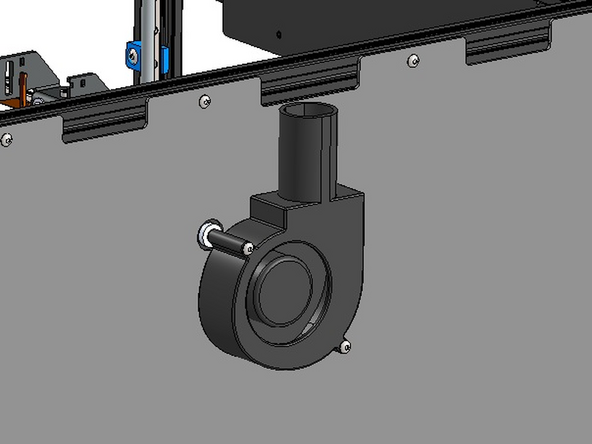

Fix the 9733 part cooling fan to the rear of the frame.

-

9733 Part Cooling Fan

-

M4 x 40mm Button Head bolt

-

M4 x 4mm Spacer

-

M4 T-Nut

-

-

-

Fix to the rear of the frame the 3D Printed cable relief bracket.

-

3D Printed Cable relief Bracket

-

M4 x 12mm Button Head Bolt

-

M4 T-Nut

-

Ensure it lines up with the fan opening.

-

-

-

Check the length of your CPAP tube, it should be 60cm long from the end of the silicone rubber side.

-

If not, use a pair of scissors to cut the open side of the tube to achieve this.

-

-

-

Fix the silicone side of the CPAP cooling hose to the Fan.

-

Secure it in place with a cable tie.

-

-

-

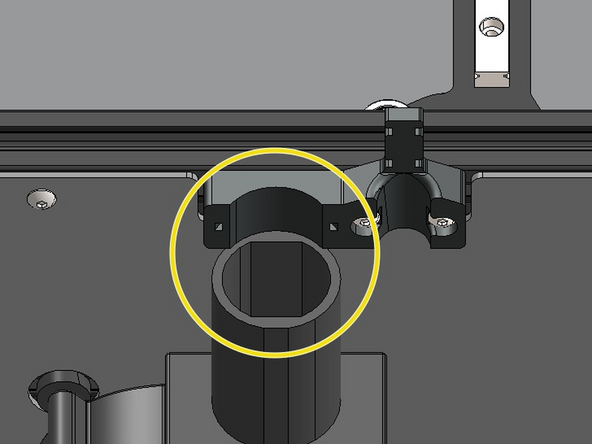

Slide the cut side of the hose onto the fan shroud.

-

Fix the fan shroud with the pipe onto the carriage using two cable ties as shown.

-

-

-

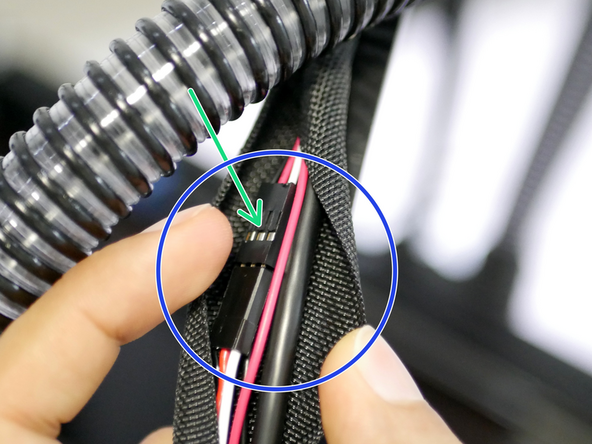

Fix to the servo the extension cable.

-

Wrap all of the cables coming from the Tool Carriage into the remaining length of the braided cable sleeving.

-

The cables should include: The Eddy USB cable, the Endstop cable and the Servo cable.

-

-

-

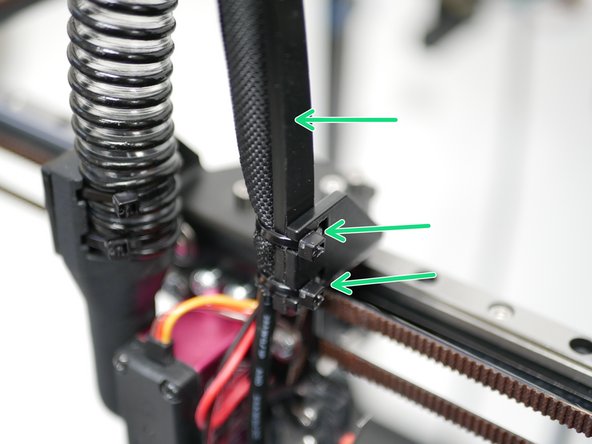

Fix the cables to the nylon cable support guide as shown using cable ties.

-

-

-

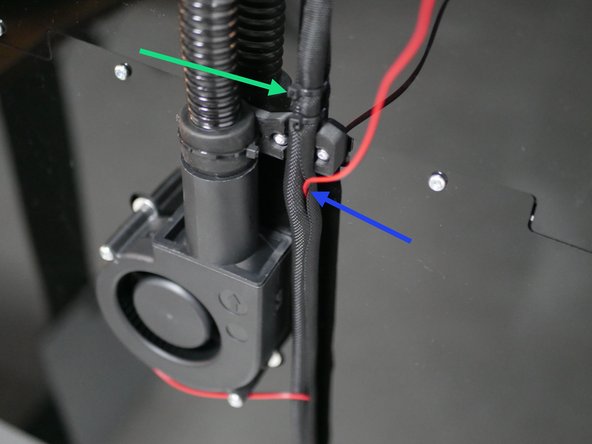

If you have the enclosure upgrade add the extension cable for the fume filter to the loom here also.

-

Fume filter fan extension cable - found in the enclosure upgrade bag.

-

The male side of the cable goes down into the base.

-

Cable tie the whole loom to the 3d printed bracket.

-

-

-

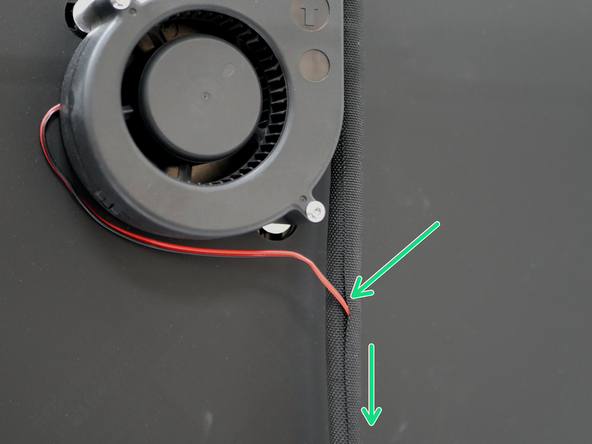

Attach to the part cooling fan its extension cable and feed and feed it into the cable sleeving.

-

Finally feed the cable loom into the rear of the base and secure with a cable tie.

-

Cancel: I did not complete this guide.

2 other people completed this guide.