-

-

If you plan to run the Proforge 3 with the Direct Drive extruder please continue to follow this guide.

-

If you intend to install the Dual Switching Hotend please continue your build from here.

-

-

-

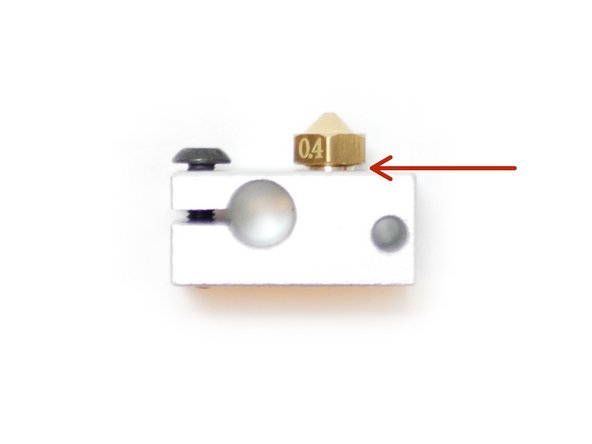

Locate these four parts for the Hotend:

-

Heatsink

-

Heater Block

-

Heatbreak

-

Nozzle

-

Secure the Heatbreak into the Heatsink.

-

-

-

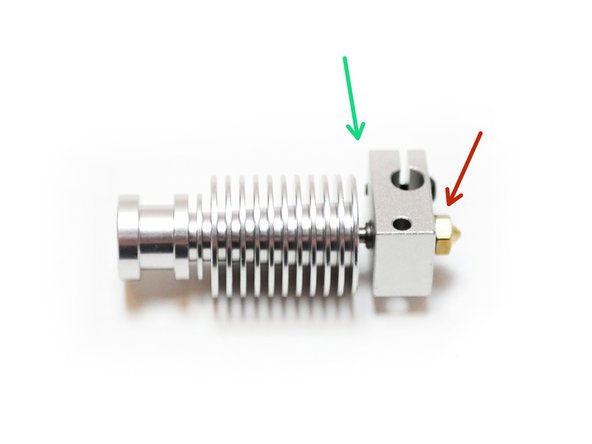

Fasten the Nozzle into the heater block.

-

Note the side that it's fastened into.

-

Also leave approximately a 1mm gap between the nozzle and heater block.

-

-

-

Fasten the Heater Block assembly to the Heatsink assembly.

-

Apply the turning force through the nozzle.

-

Be careful not to apply too much force when tightening, as it may cause the heatbreak to snap!

-

-

-

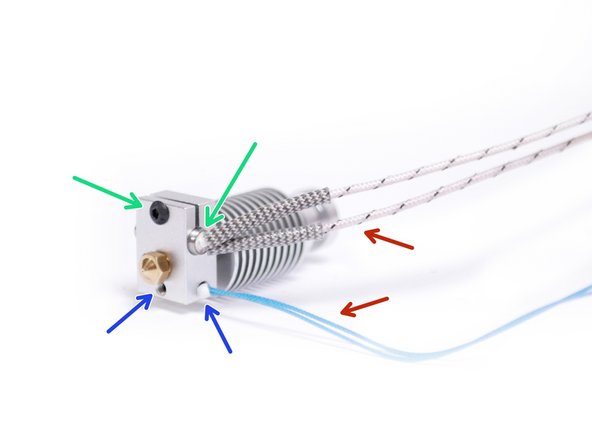

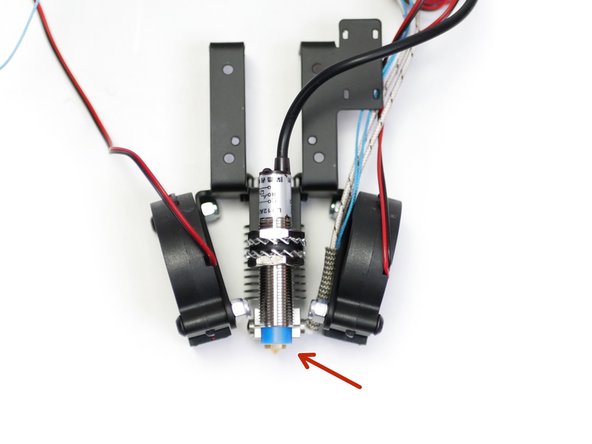

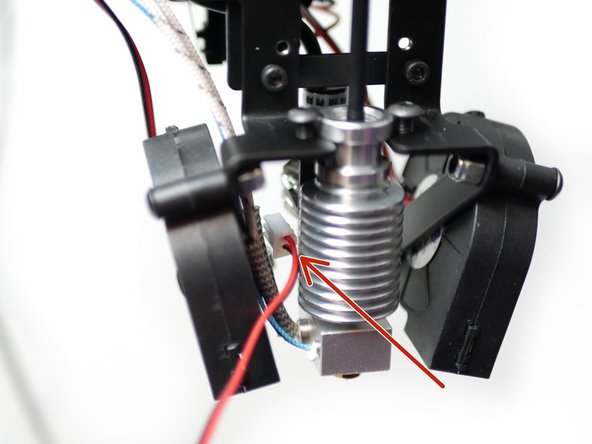

Fix the heater cartridge as shown. Tighten this bolt to secure it.

-

Slide the thermistor cartridge in place. Tighten this set screw to secure.

-

Make sure that the cables are point out of the side shown.

-

-

-

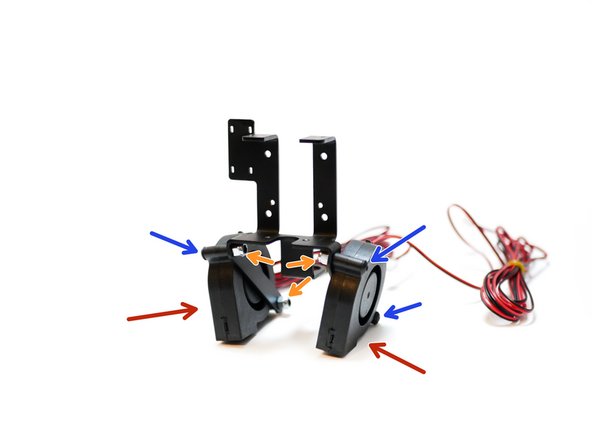

Locate the Direct Drive Mount bracket.

-

Secure to it the two 50mm blower fans as shown.

-

M4 x 22mm Button (x4)

-

M4 Nyloc Nut (x4)

-

-

-

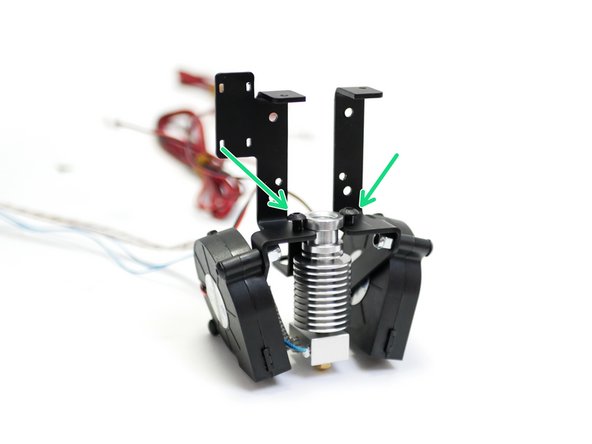

Fix the Hotend to the Mount with two M4 x 8mm button bolts.

-

Ensure the Hotend is pushed all the way into the mount.

-

Ensure that the Hotend's cables point to the left.

-

-

-

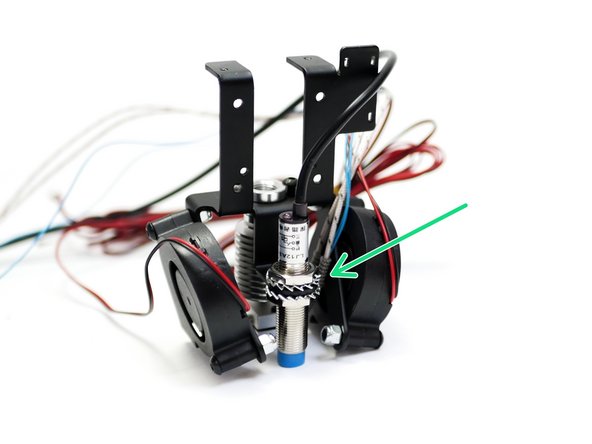

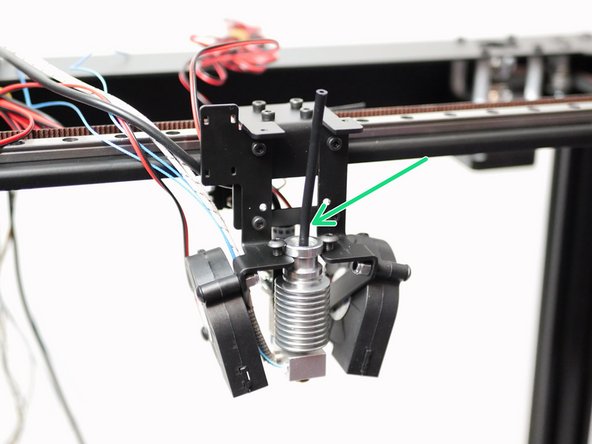

The probe is secured to the back of the Mount as shown.

-

The bottom of the probe should be between 1-2mm above the tip of the nozzle.

-

-

-

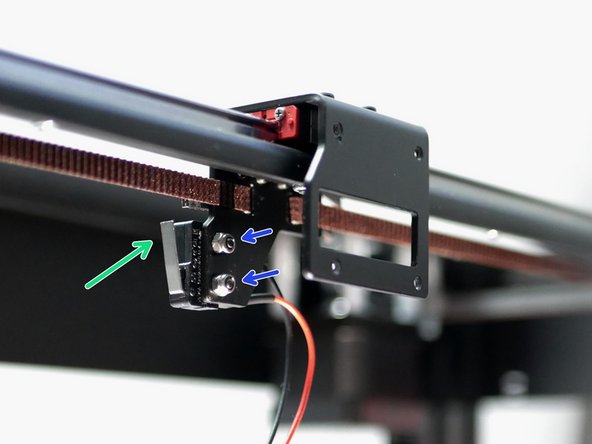

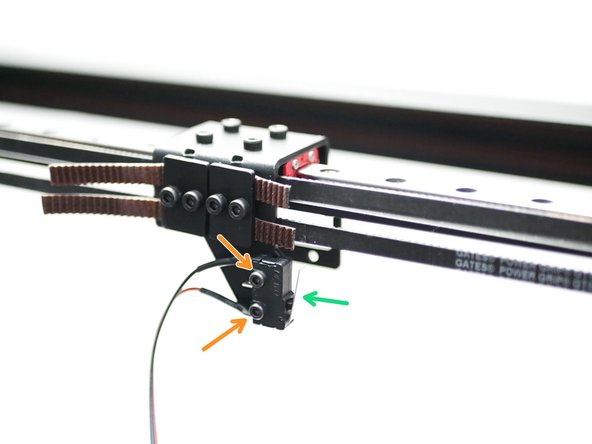

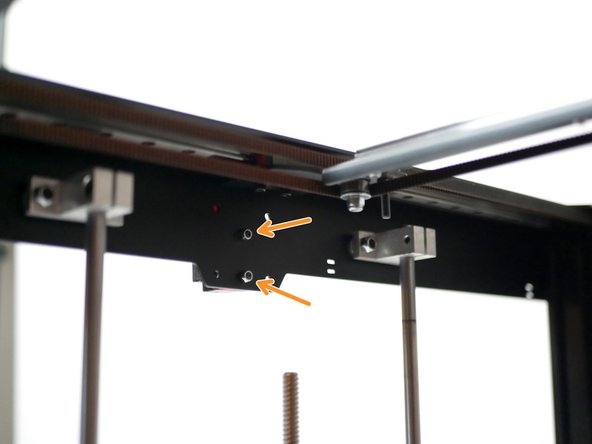

Install the X-Endstop as shown.

-

Note that the X-Endstop is the one with the longer 2M cable.

-

M2.5 x 12mm Bolt

-

M2.5 Nyloc Nut

-

-

-

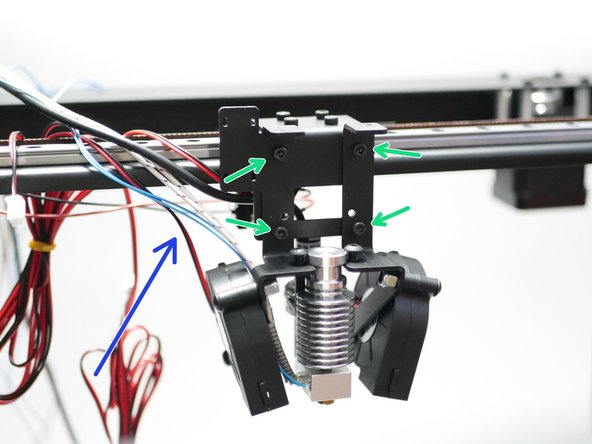

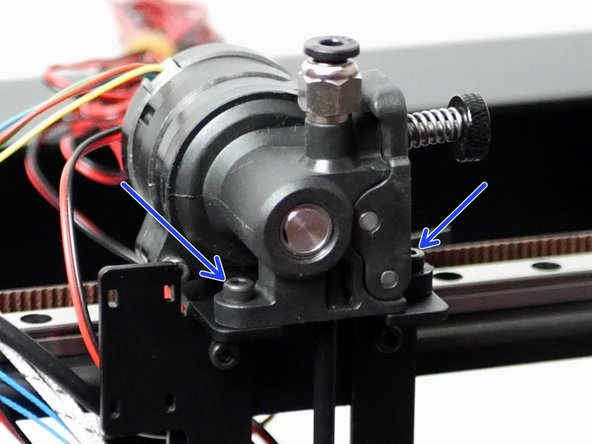

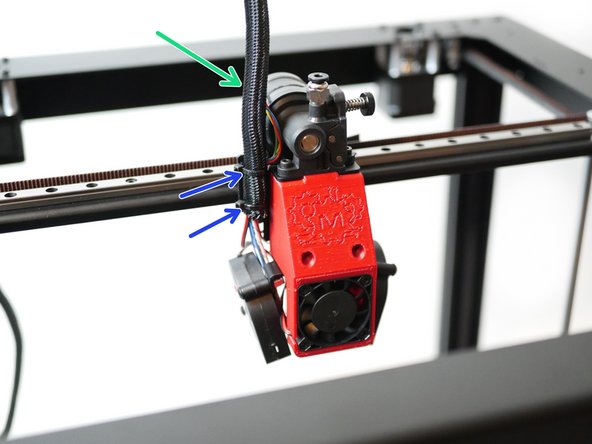

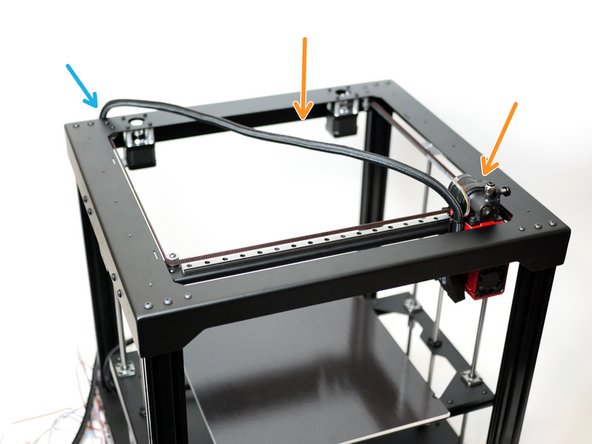

Secure the Mount to the Tool Carriage on the gantry.

-

M3 x 6mm Cap Bolt

-

Have the cables come out of the left side of the mount.

-

-

-

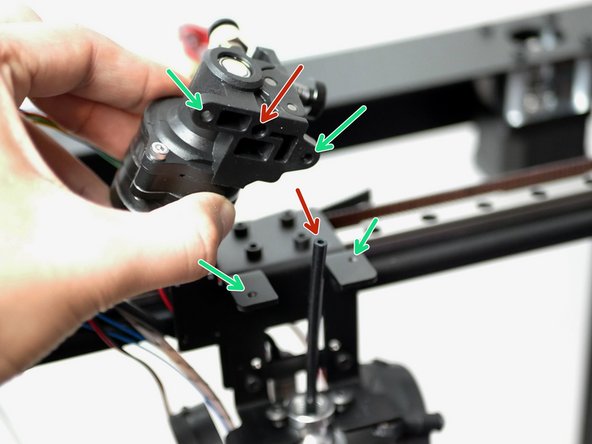

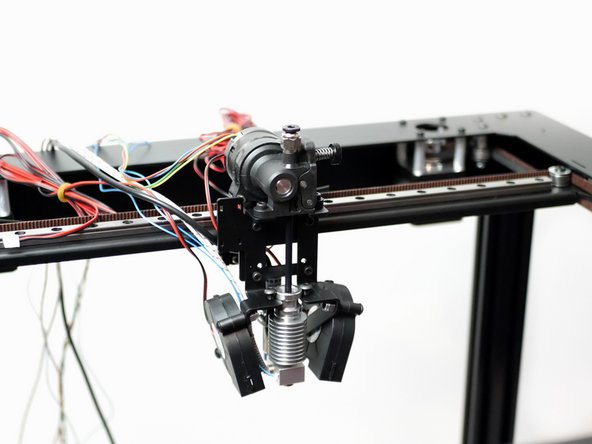

Secure the Orbiter Extruder as shown.

-

The mounting holes line up with those on the hotend mount.

-

The PTFE tube goes into this hole.

-

Secure with two M3 x 8mm Cap head bolts.

-

-

-

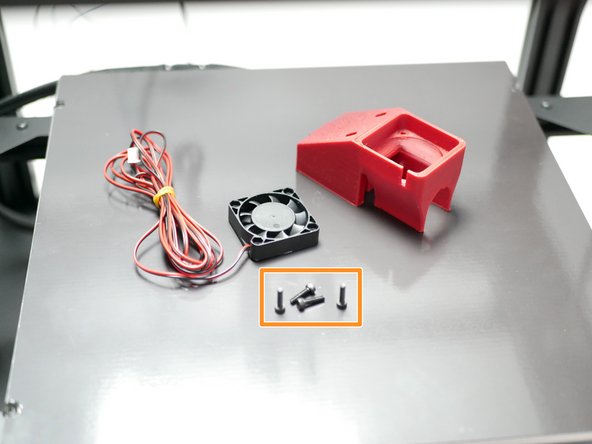

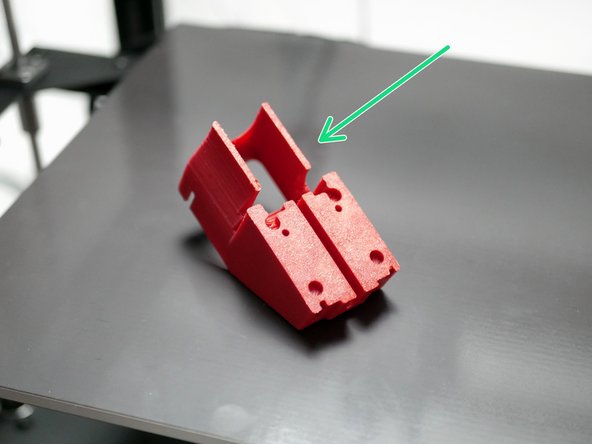

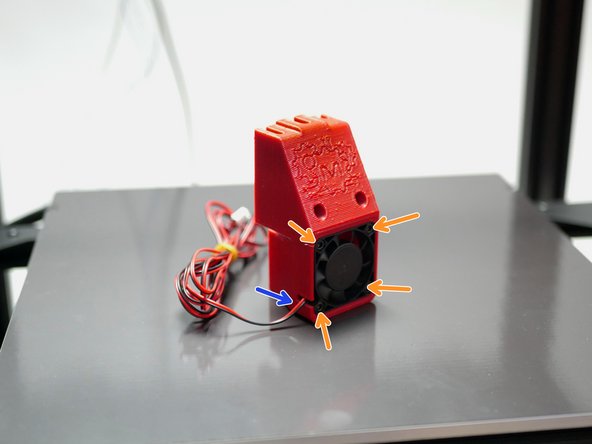

Take the 3D printed mount and remove the support raft from underneath.

-

Fix the fan with 4 M3 x 12mm bolts.

-

Ensure the fan is installed sticker side in and with its cable aligned with the slot.

-

-

-

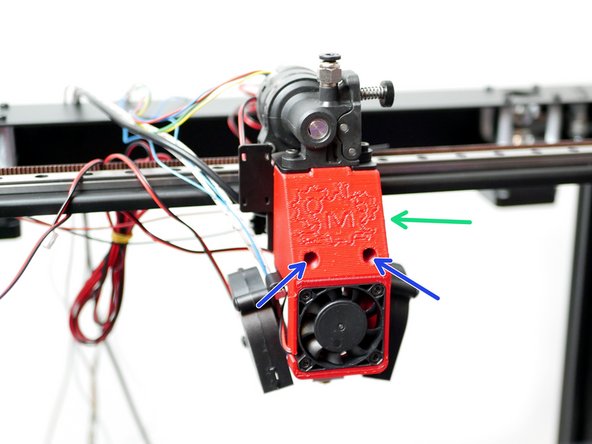

Begin by feeding the fans cable into the left side of the mount as shown.

-

Push the cooling fan mount assembly onto the metal mount.

-

Secure with two M3 x 20mm bolts. Avoid over tightening.

-

Before continuing, use a marker to mark the hotend cooling fan's connector, this will come in handy later when wiring.

-

-

-

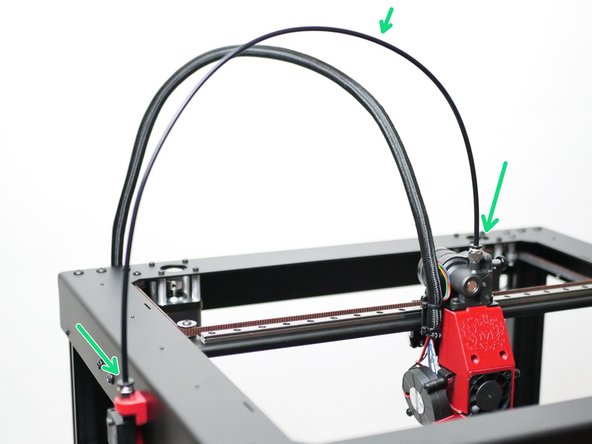

Use the braided sleeving to wrap the cables from the tool head.

-

Use two cable ties to secure it to the hotend mount as shown.

-

Extend the tool head to the bottom right corner.

-

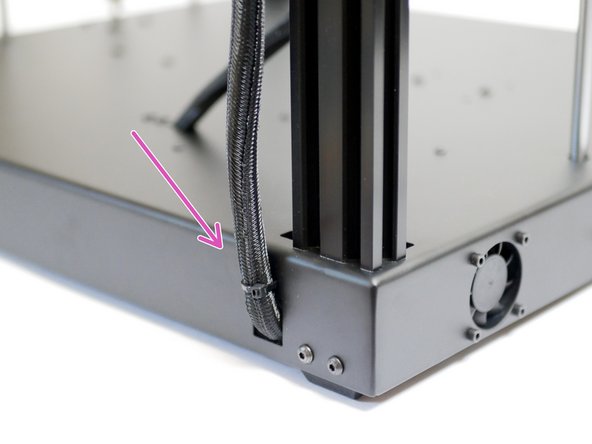

Secure the other side of the cable loom to the rear of the printer.

-

Feed all of the cables into the base. Fix the loom to the base with cable ties.

-

The Orbiter cable is short, but included is a black extension cable, use this to reach the control board.

-

-

-

Take the filament sensor mount and fix to it the PC4 Coupling. The coupling can thread straight into it, you will need to use a pair of pliers to turn and secure it.

-

Secure it along with the filament sensor to the side of the printer.

-

You can secure it to either side of the printer.

-

M3 x 25mm Cap bolt

-

M3 Nyloc Nut

-

-

-

Finally, attach the PTFE tube from the filament sensor assembly to the Orbiter Extruder.

-

The length of the tubing should be approx 60cm.

-

Cancel: I did not complete this guide.

2 other people completed this guide.

2 Comments

I cut the tubing for run from the motor to the hotend to 3 1/2 inches (89 mm), which is very slightly too short - 3 9/16 (90.5 mm) would probably be better. The guide just shows “…” right now.

Greg Murnane - Resolved on Release Reply