-

-

Use a thick lithium based grease in these areas to ensure that the Tool Changer mechanism operates optimally.

-

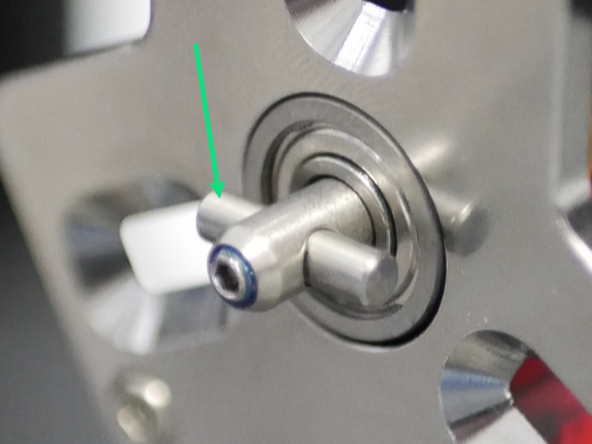

Mechanism Spring

-

Servo Shaft

-

Tool Plate Key Hole (inside)

-

Reapply the grease every 1-2 months or sooner if you notice increased noise or a higher rate of wear on the cam pin.

-

-

-

Lubricate rails with a Lithium or PTFE or Synthetic based grease.

-

Lubricate every ~6 months or sooner if you notice increased noise, jerky motion, or visible gunk/dryness/rust on the rails.

-

Applying the grease:

-

Wipe rails clean of old grease, dust and debris.

-

Apply new grease across the length of the rail.

-

Work the grease in by moving the carriage back and forth.

-

Remove any excess.

-

-

-

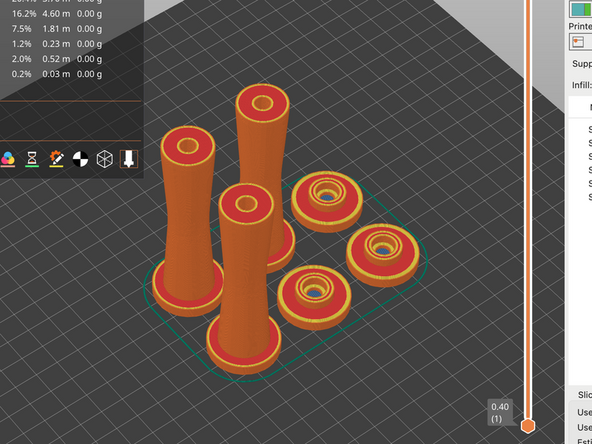

As tool changes are performed friction will cause wear to the mechanism. We have designed the cam shaft to take this wear whilst also making it cheap and easy to replace. The kit comes with 2 pins.

-

Rated for ~10,000 Tool Swaps

-

Available here.

-

-

-

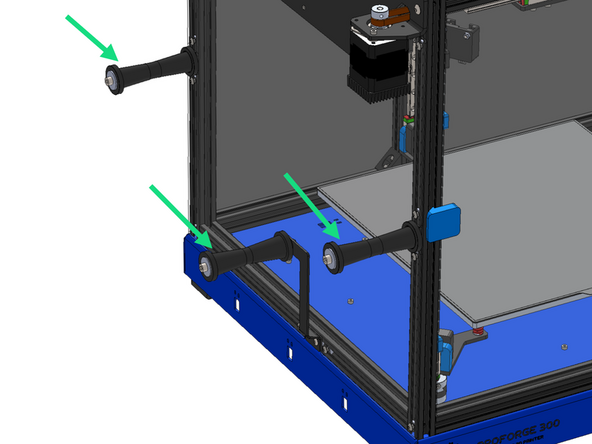

Designed to go over the Spool Holder bolt to provide a cleaner finish.

-

Download here.

-

Assemble by sliding both parts onto the M5 bolt, then secure to frame or bracket as shown.

-

Almost done!

Finish Line