-

-

The second extruder is identical to the first and installed in the same way as outlined in Stage 8.

-

Begin by fixing the extruder face plate and motor to the mount with a single M3x8mm bolt.

-

The motors cable connector should be pointing to the back of the bracket.

-

Ignore the PTFE tubing if building from the Proforge 2/2S guide.

-

-

-

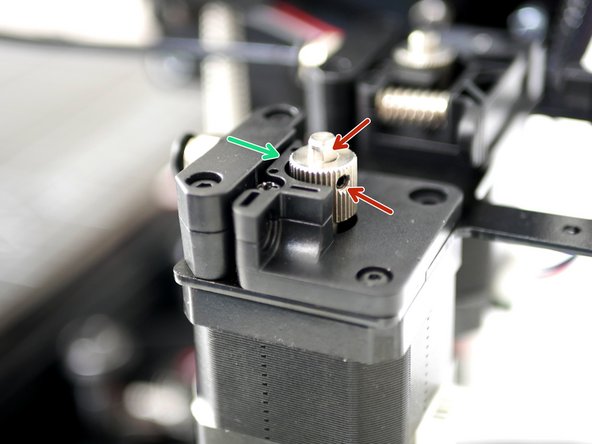

Fix the Drive Gear to the shaft of the motor.

-

The top of the drive gear should only be a few millimetres above the top of the back plate.

-

Tighten the set screw onto the flat of the shaft. Tighten firmly.

-

-

-

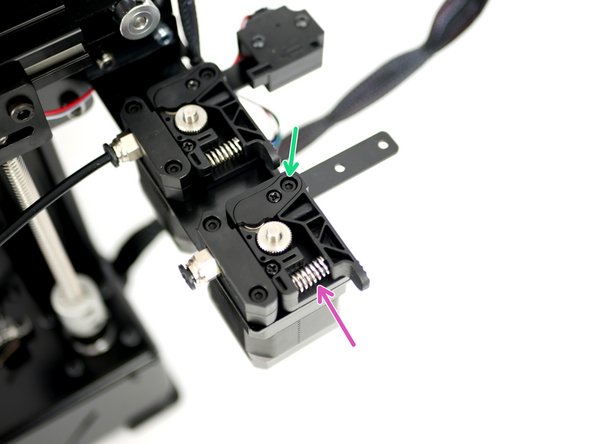

Place in position the Extruder Spring on the Back Plate.

-

Drop in a M3 x 18mm bolt.

-

Compress the spring with the Idler Arm and tighten down the M3 x 18mm bolt.

-

Do not over tighten, the arm should still be able to pivot.

-

-

-

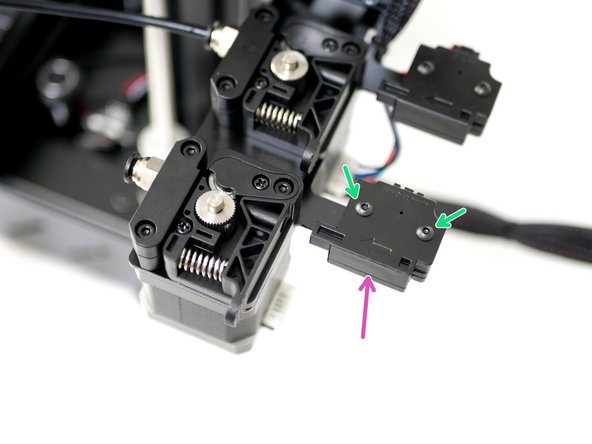

Fix the filament sensor to the Extruder Mounting Bracket:

-

Filament Sensor

-

M3 x 20mm bolt

-

M3 Nyloc Nut

-

Match the orientation of the Filament Sensor as shown in the photos.

-

-

-

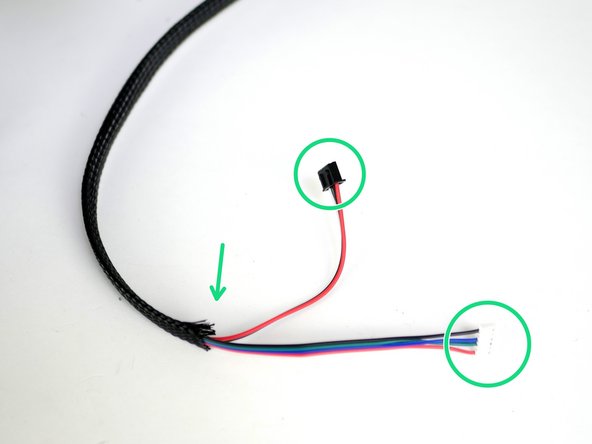

Cut 70CM of Braided Cable sleeving

-

Melt the ends with a lighter to prevent them from fraying out.

-

Feed the cable sleeving over the extruder motor and filament sensor cable as shown.

-

Like shown in the second image, the sides of the cables that connect to the motor and filament sensor should be on the same side of the sleeving.

-

-

-

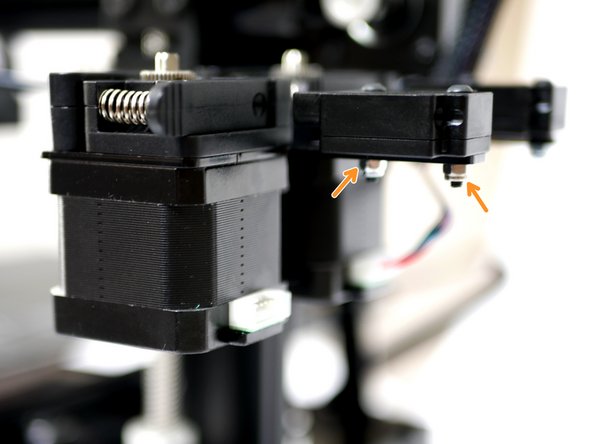

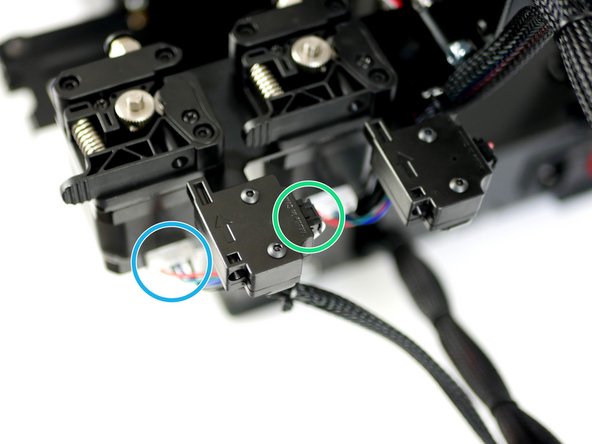

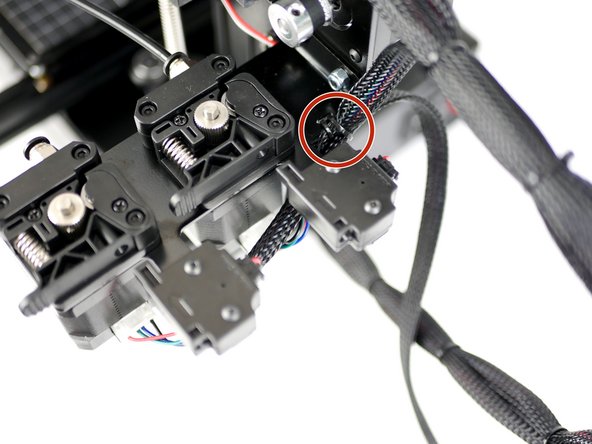

Connect the filament sensor cable to the filament sensor.

-

Connect a motor cable to the motor.

-

Cable tie the cables to the mounting bracket.

-

Cancel: I did not complete this guide.

16 other people completed this guide.