-

-

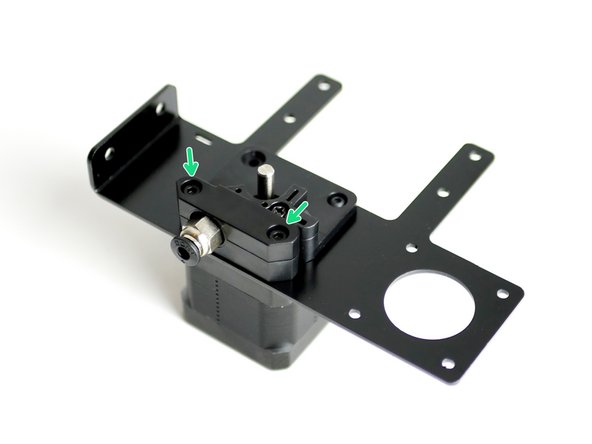

Place the Extruder Mounting Bracket onto a motor. The motors pin connector should be pointing to the back of the bracket like shown.

-

Secure the extruder back plate with a single M3 x 8mm bolt through the top right hole.

-

-

-

Fix the Coupling Bracket onto the motor with two M3 x 18mm cap head bolts.

-

-

-

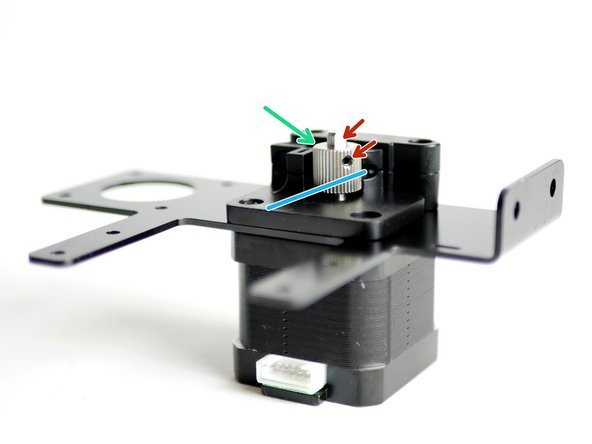

Align the drive gear so that it runs with the filaments path.

-

Filament path

-

Fix the Drive Gear to the shaft of the motor.

-

Tighten the set screw onto the flat of the shaft. Tighten firmly.

-

-

-

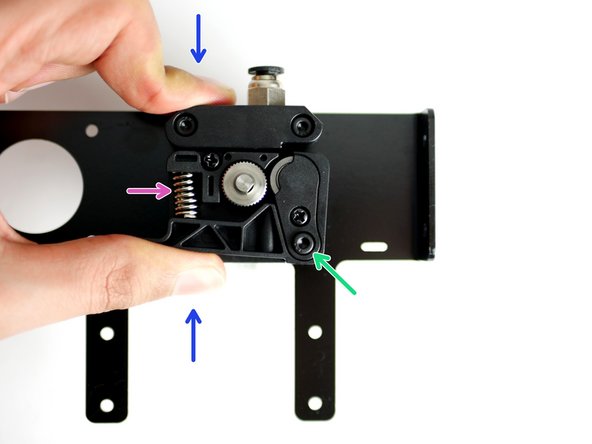

Place in position the Extruder Spring on the Back Plate.

-

Drop in a M3 x 18mm cap head bolt

-

Compress the spring with the Idler Arm as shown in the first image.

-

Tighten down the M3 x 18mm bolt

-

Do not over tighten, the arm should still be able to pivot.

-

-

-

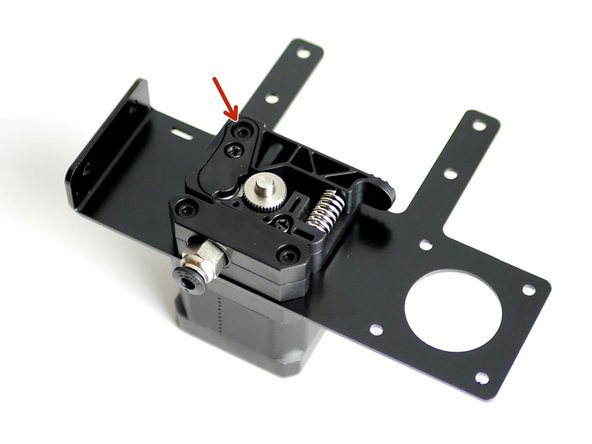

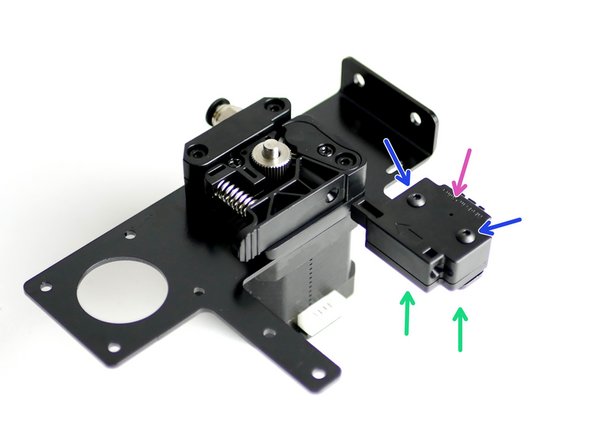

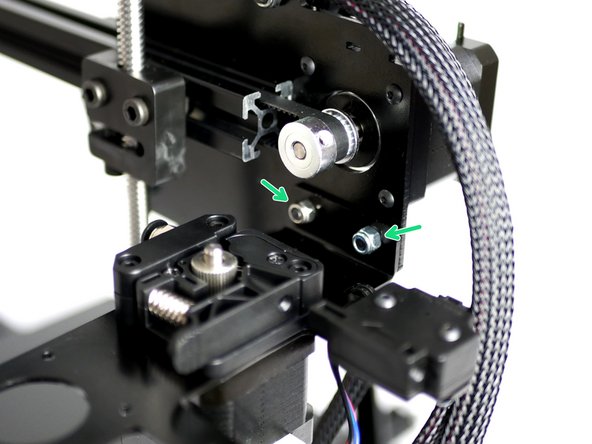

Fix the filament sensor to the Extruder Mounting Bracket:

-

Filament Sensor

-

Two M3 x 20mm bolts

-

Two M3 Nyloc Nuts

-

Match the orientation of the Filament Sensor as shown in the photo.

-

-

-

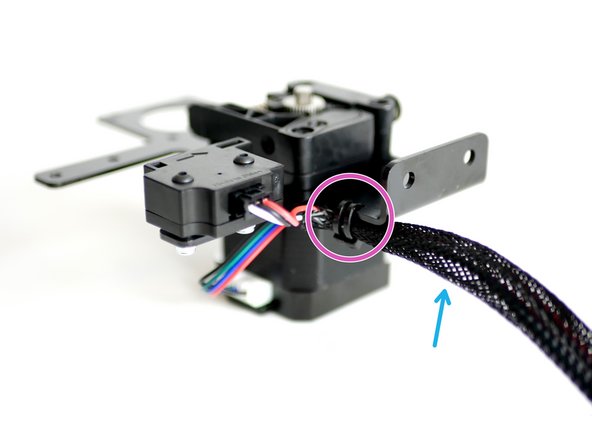

Cut 60CM of Braided Cable sleeving

-

Melt the ends with a lighter to prevent them from fraying out.

-

-

-

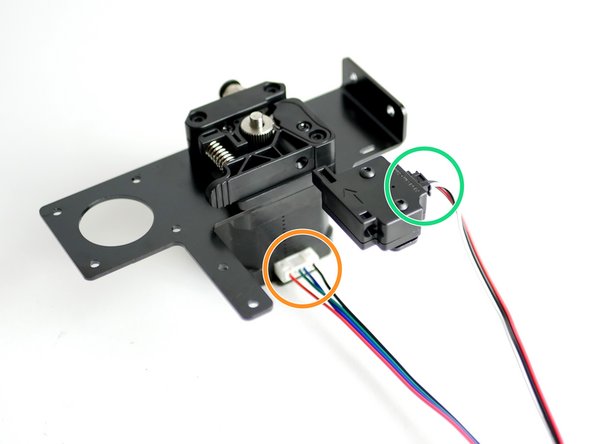

Connect the filament sensor cable to the filament sensor.

-

Connect a motor cable to the motor.

-

Feed onto both of the cables the braided cable sleeving.

-

Cable tie the cables to the mounting bracket.

-

-

-

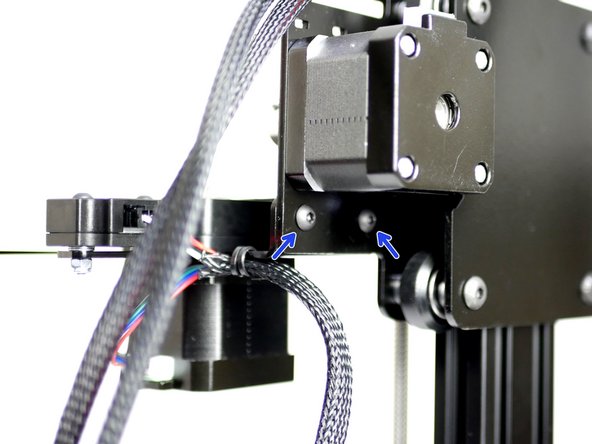

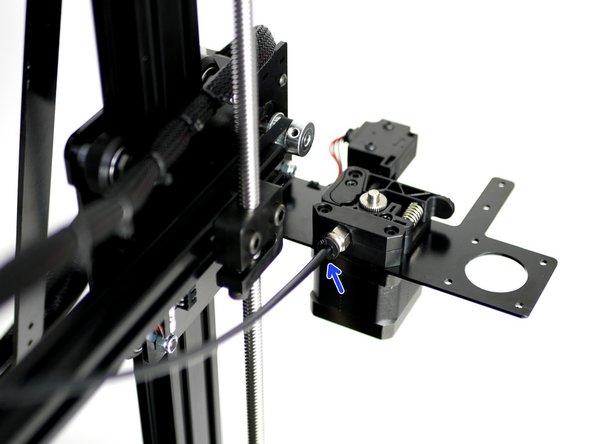

Fix the Extruder Assembly onto the Z-Carriage

-

M4 x 10mm bolt

-

M4 Nyloc Nut

-

-

-

If you are building the Proforge 2/2S with the Dual Switching Extruder stop here and continue the build guide from the Dual Switching Extruder guides here.

-

-

-

Slide onto a M5 x 100mm bolt an M5 15mm washer.

-

Fix to the bolt an M5 Nyloc Nut about 1cm of the way up.

-

Fix the bolt to the top of the Extruder Mount with another M5 Nyloc nut.

-

-

-

If you do not intend on installing the Dual Switching Extruder you can cut the tubing down to 50CM before installing.

-

Insert one end into the PTFE Tubing into coupling on the Extruder.

-

Insert the other end of the PTFE Tubing into the Hotend, make sure that it is fully inserted up to the nozzle.

-

Cancel: I did not complete this guide.

20 other people completed this guide.