-

-

Carefully open the box from the top, as indicated by the "This Way Up" labels.

-

Remove the top layer of packaging.

-

Remove the enclosure panels.

-

Remove the foam from the sides of the box.

-

Picking it from the sides, pull the printer out of the box.

-

-

-

Depending on your configuration, you should have the following:

-

Proforge 3D Printer

-

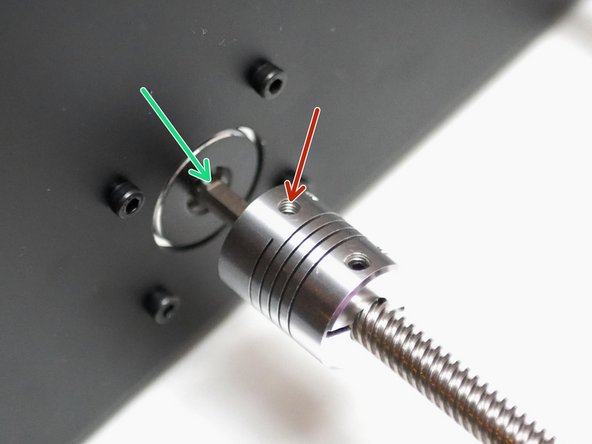

Lead Screws and Couplings. (These are disassembled in recent assemblies to prevent damage to them)

-

A box containing the following: Touch Screen, SD Card, Spool Holder, Power Cable, Hotend Cover.

-

Dual Switching Hotend Config: Two Extruders, Direct Drive Assembly, Direct Drive Accessories Bag.

-

Enclosure: Enclosure Panels, Enclosure Roof, Fume Filter, Fasteners.

-

OctoPi: 4GB SD card, Blue USB Cable, White USB Cable

-

-

-

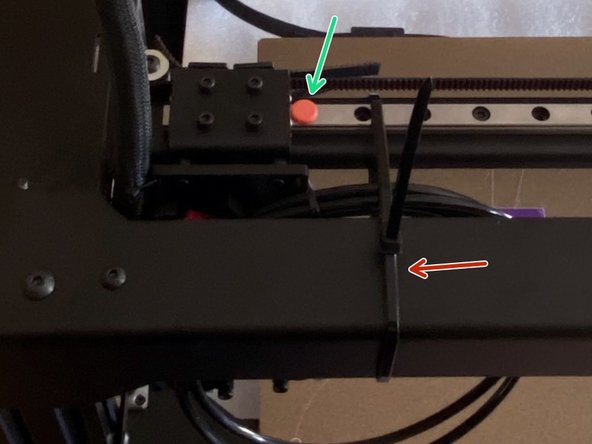

Cut the cable tie holding the gantry.

-

Also remove the orange stopper.

-

Cut the cable ties holding the bed down also.

-

-

-

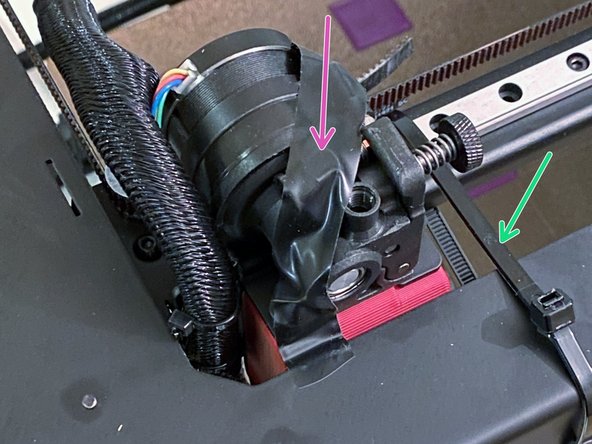

Cut the cable tie and remove the orange stopper from the rail.

-

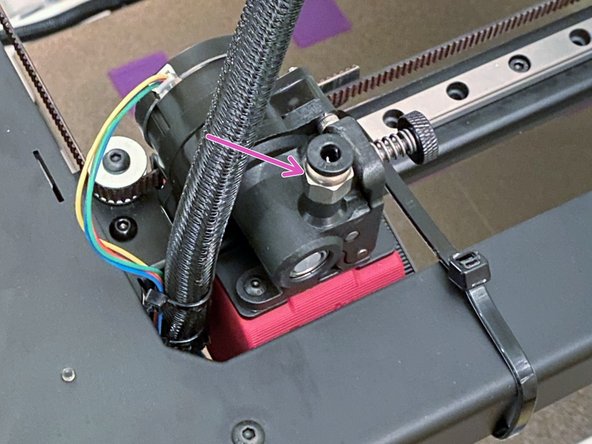

Remove the tape from the print head and fix the coupling onto the extruder.

-

-

-

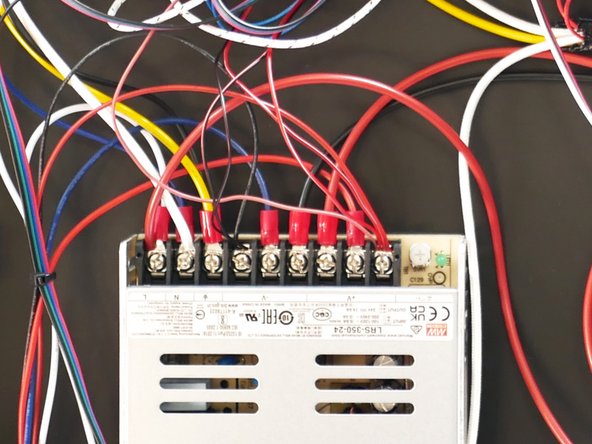

Place the printer onto its side and check that the power supply is set to your mains voltage.

-

Incorrectly setting this and powering on could damage your PSU.

-

-

-

Double-check the wiring in general in case anything has come loose during shipping.

-

Especially double-check the terminals on the power supply. They should all be firmly tightened down.

-

Wiring Diagram

-

-

-

-

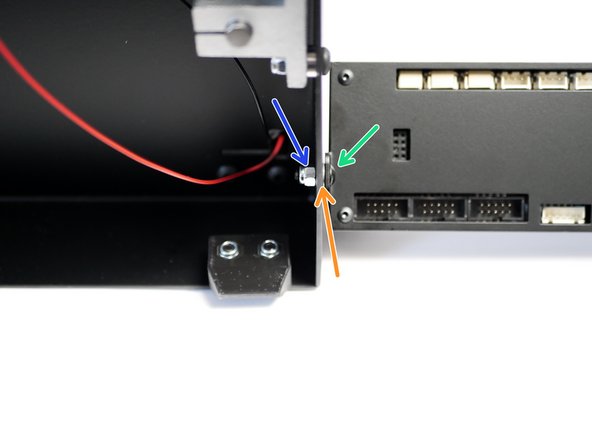

Attach the touch screen case assembly to the bottom left of the base of the printer as shown.

-

M4 x 10mm bolt

-

M4 Washer

-

M4 Nyloc

-

-

-

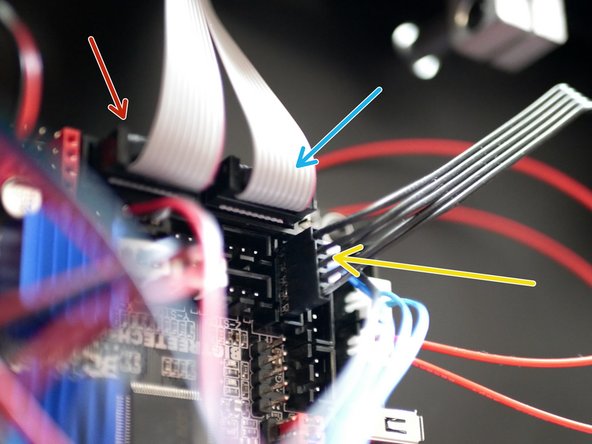

Black cable: This is for controlling the printer through the touch screen interface via serial.

-

The two white cables are for controlling the printer directly via marlin's interface through emulation mode.

-

EXP 1

-

EXP 2

-

Black cable - board side.

-

Note the orientation of the loose connector and the 4-pin connector, match as shown in the third image.

-

-

-

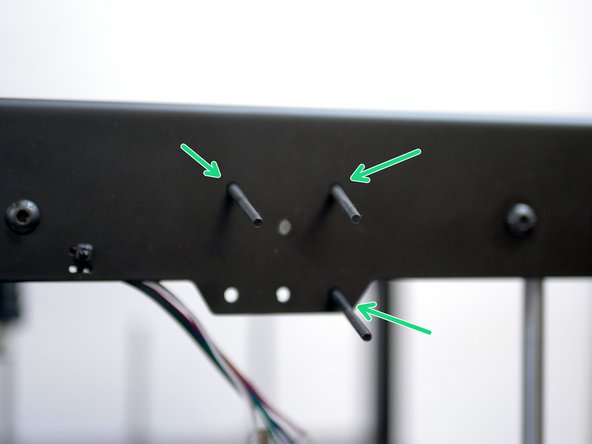

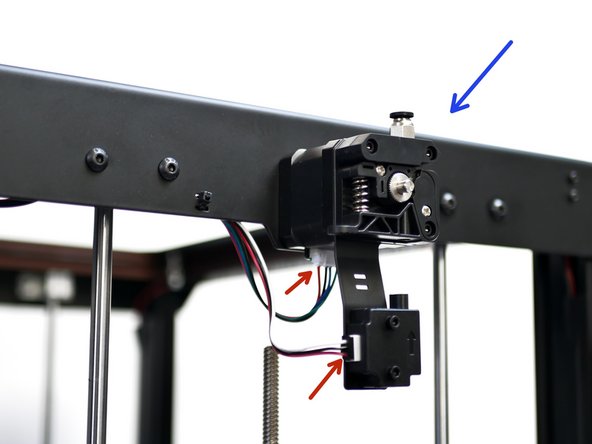

Take these three bolts and remove them from the back of the extruder.

-

Feed them into holes on the top panel, from the inside.

-

Secure the extruder onto the top panel.

-

Fix the cables into the motor and filament sensor as shown.

-

Repeat the same on the other side of the top panel also.

-

-

-

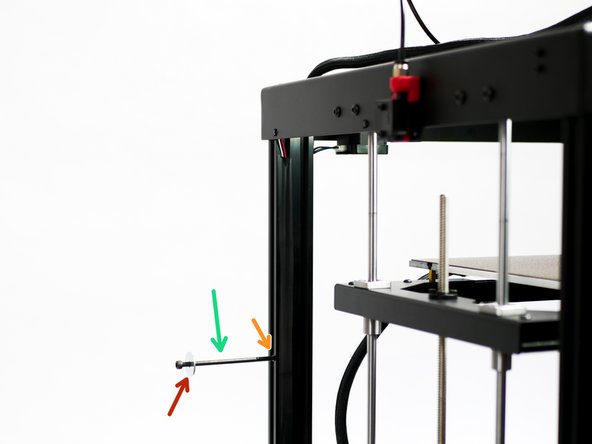

Fix the spool holder assembly to the side of the printer:

-

M5 x 100mm Bolt

-

M5 Penny Washer

-

M5 T-Nut

-

With the Dual Switching Hotend setup this needs to be done on both sides of the printer.

-

-

-

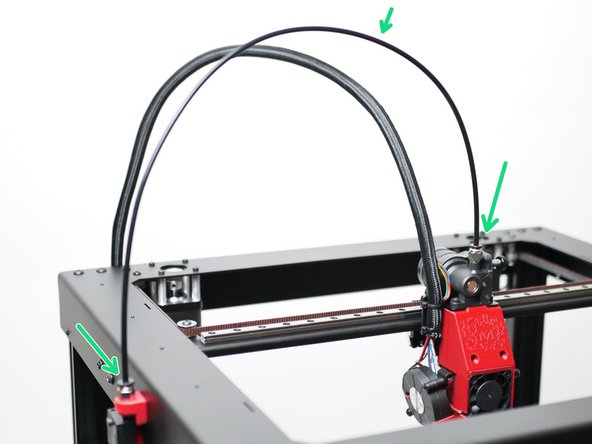

DSH: Fix the PTFE tubing from the hotend to the extruders. The left side of the hotend goes to the left extruder and vice versa.

-

Direct Drive: Fix the PTFE tubing from the orbiter extruder to the feeder on the left side of the printer.

-

-

-

Plug the power cable into the back of the printer.

-

Power on with the switch on the front of the base.

-

If you find your power switch getting stuck 'ON', it is likely secured on too tightly. Loosen the nut holding it to the base.

-

-

-

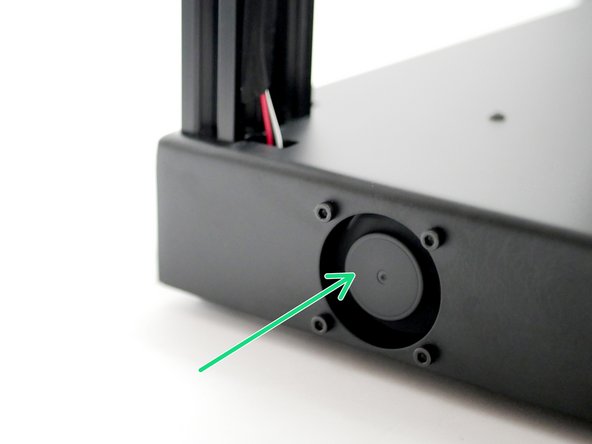

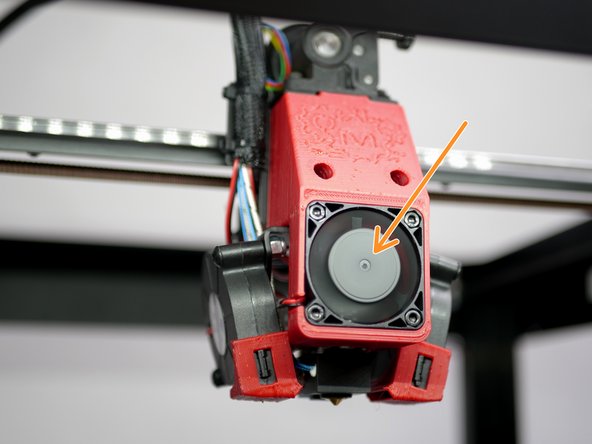

Powering on for the first time should result in the following:

-

Electronics Fan should spin.

-

Hotend Cooling Fan/s should spin

-

LED's should light up.

-

-

-

Everything should already be set-up, but to be safe we recommend running through all of the pre-flight steps here:

-

-

-

-

-

Follow the steps here for your first print:

-

-

-

-

-

Follow the guide here for installing the Enclosure. Some steps have already been done for you.

-

Almost done!

Finish Line