-

-

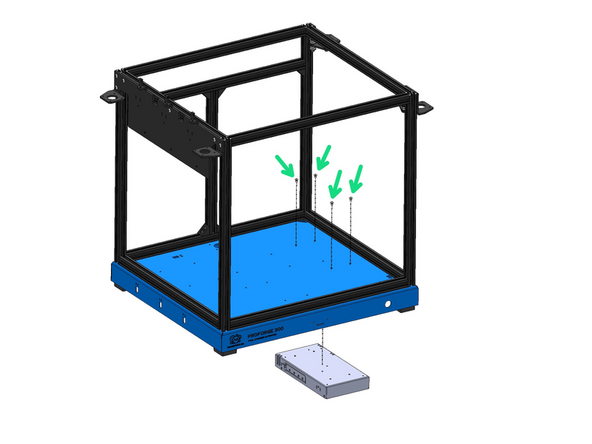

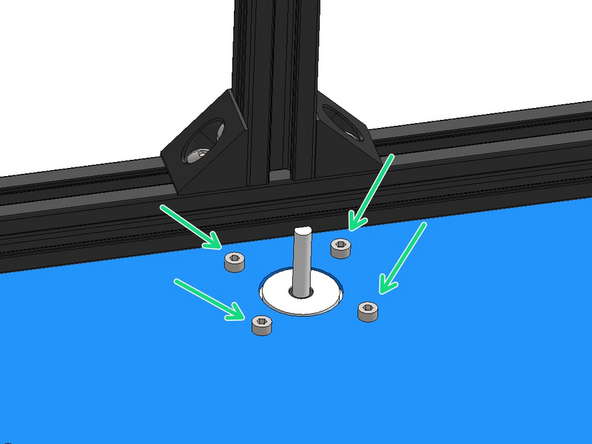

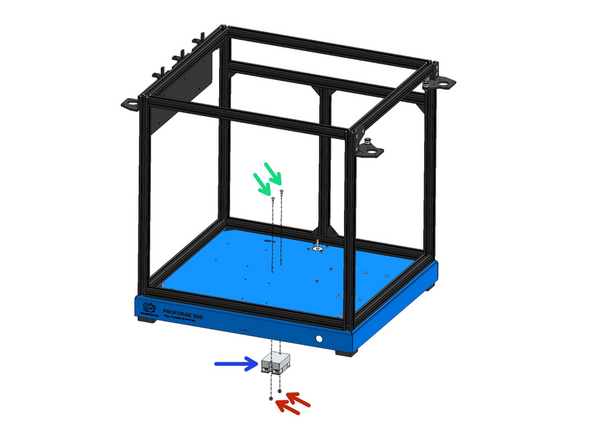

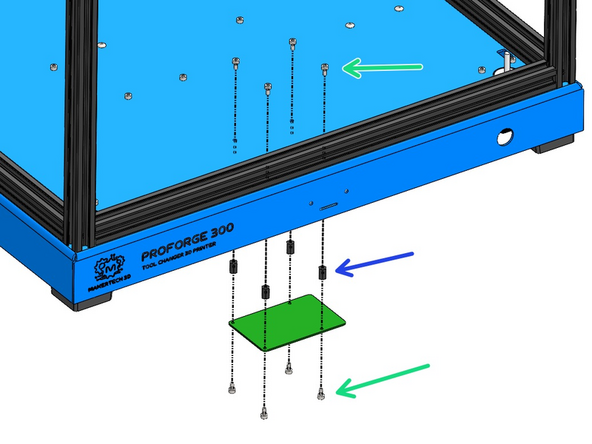

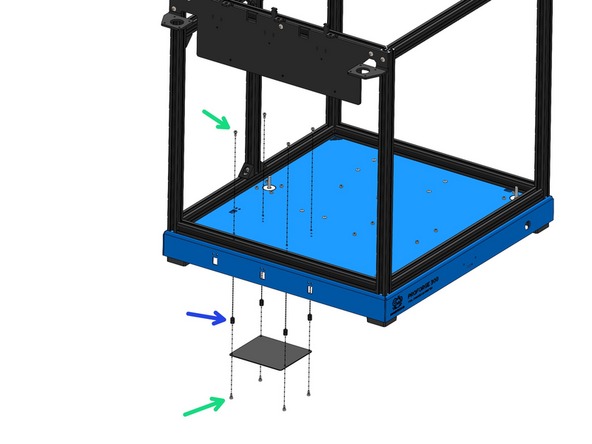

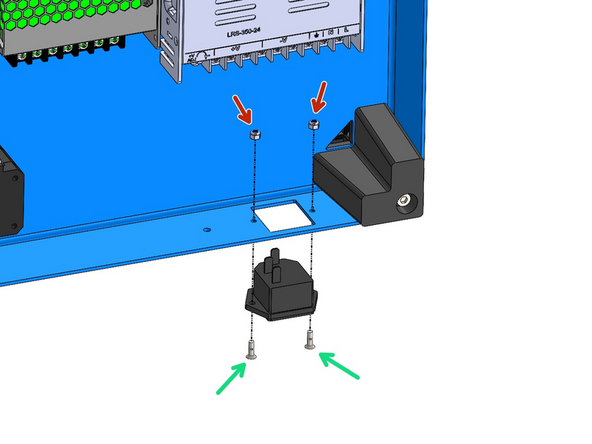

Mount the Base with the rubber feet to the bottom of the Frame Assembly.

-

Base

-

Rubber Foot

-

Include an M5 Washer here

-

M5 x 60 Cap Head Bolt

-

The bolt should thread directly into the bottom of the extrusion.

-

-

-

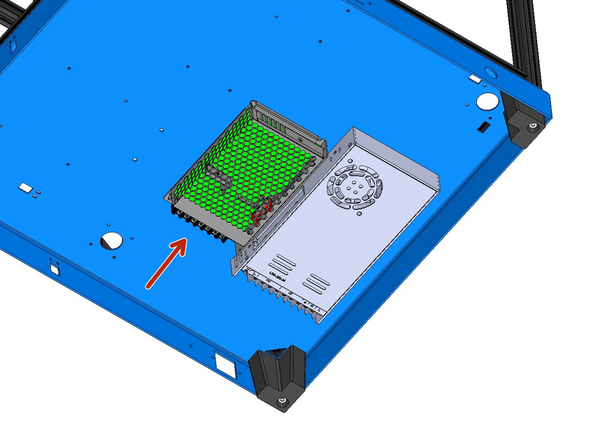

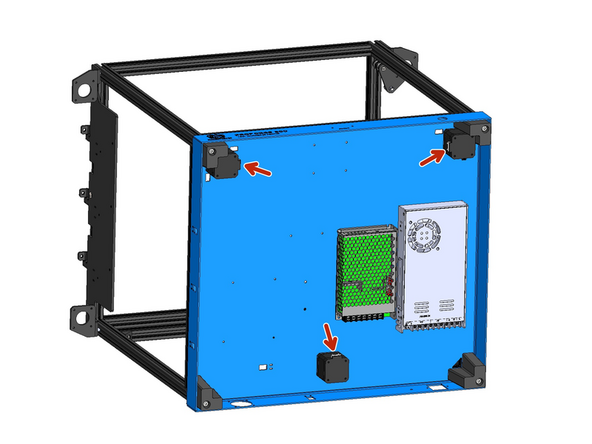

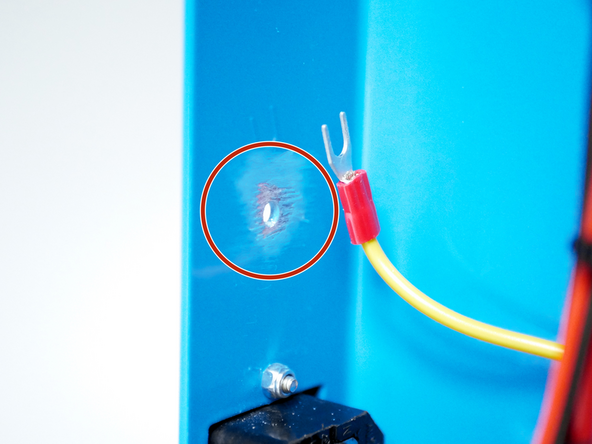

Scuff the paint on the inside of the rear of the base to allow the earth point to make contact.

-

OR use a 4mm drill bit to remove the paint from the inside of the hole.

-

You only to expose a little to for it to be effective.

-

-

-

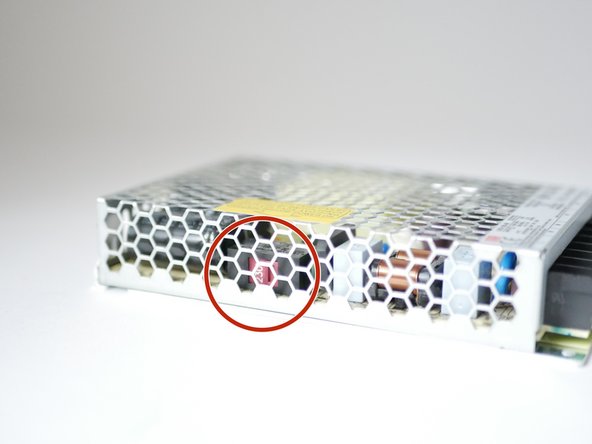

Before mounting the 24v PSU, check that its input voltage is set correctly.

-

The switch on the side of the unit should be set to your mains voltage. For example, in Europe this would be 230v, and in North America it would be 110v.

-

-

-

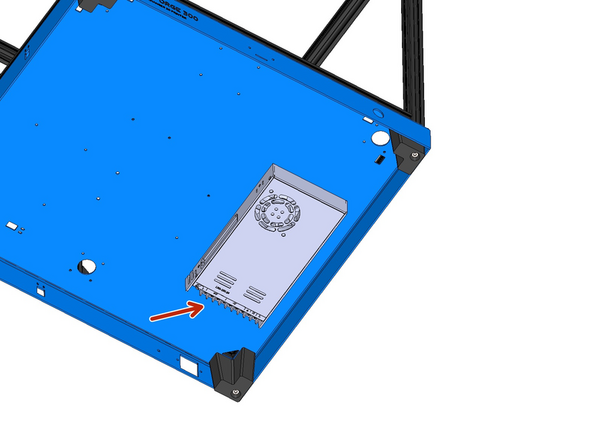

Mount the 24V PSU to the base.

-

M4 x 6mm Button Head Bolts

-

Ensure it's mounted with the terminals pointing to the rear of the machine.

-

-

-

Before mounting the 48v PSU, check that its input voltage is set correctly.

-

The switch on the side of the unit should be set to your mains voltage. For example, in Europe this would be 230v, and in North America it would be 110v.

-

-

-

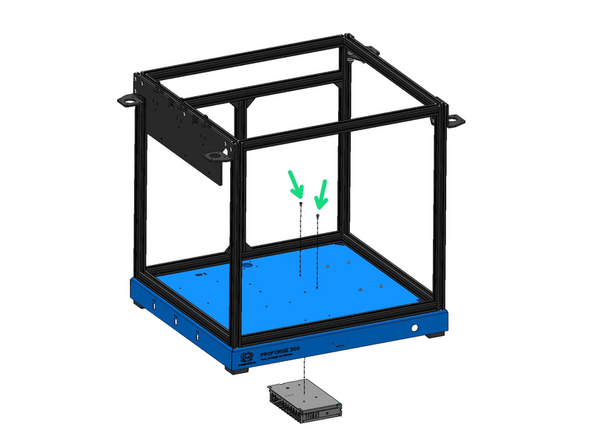

Mount the 48V PSU to the base.

-

M3 x6mm Cap Head Bolt

-

Again - ensure it's mounted with the terminals pointing to the rear of the machine.

-

-

-

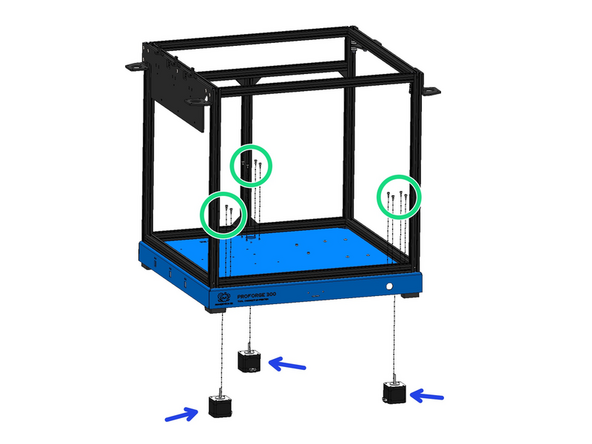

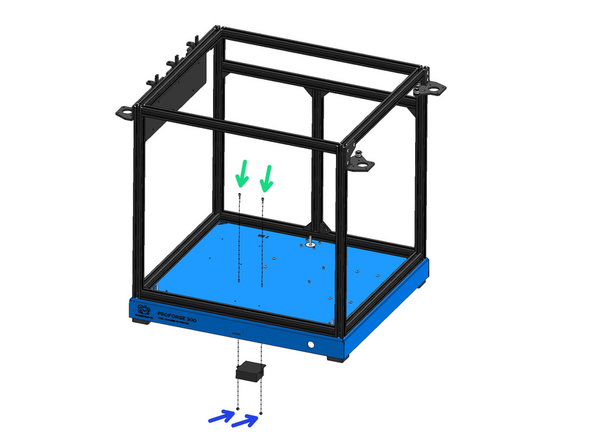

Mount the three NEMA-17 Motors to the base with M3 x 6mm cap head bolts.

-

These are the smaller BQ marked motors.

-

Ensure that the cable connectors on the motors are all facing inwards under the base as shown.

-

-

-

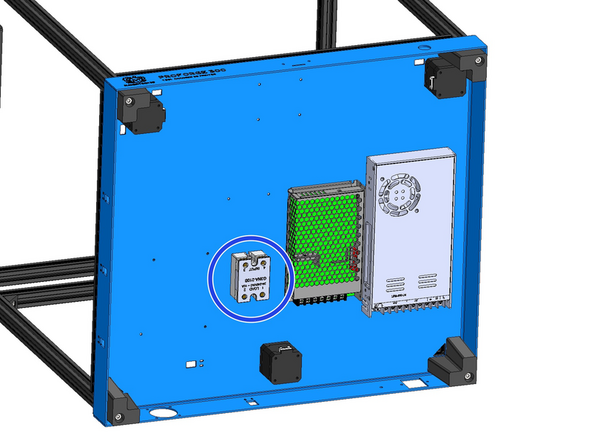

Mount the SSR Relay to the base.

-

M4 x 12mm Button

-

M4 Nyloc

-

Mount the SSR with the load side terminals facing the rear of the base.

-

Bolt orientation is purely aesthetic, feel free to install the other way round (easier), with the nut on the top side of the base.

-

-

-

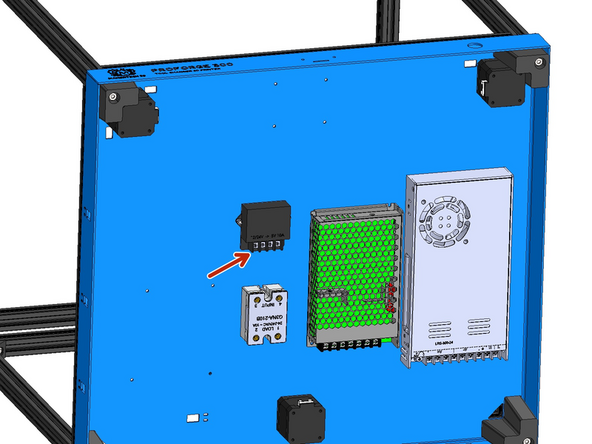

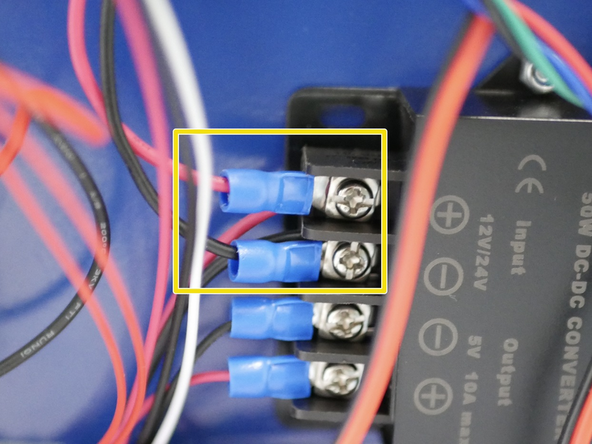

Mount the 5V Power Convertor to the base.

-

M3 x 8mm Bolt

-

M3 Nyloc Nut

-

Orientate the power convertor so that its terminals are facing the rear of the base as shown.

-

-

-

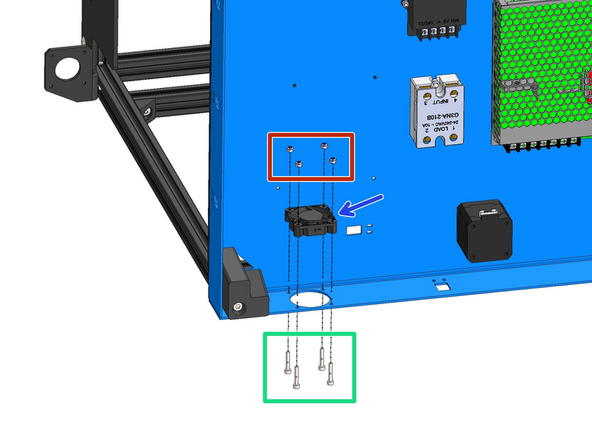

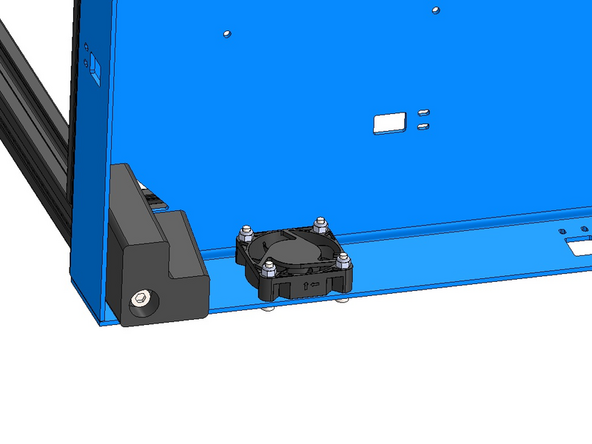

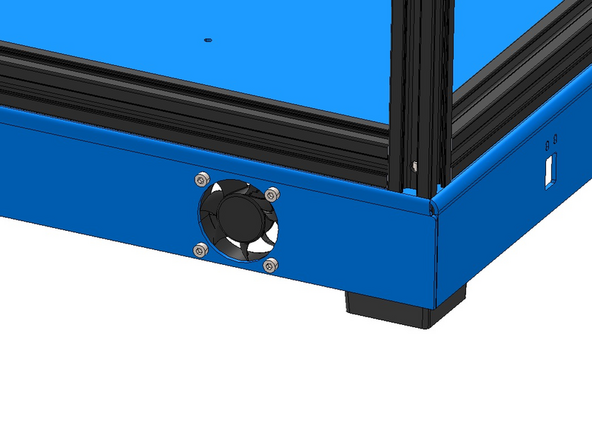

Mount the 40mm fan as shown - orientate the cable so it points to the top of the base.

-

Install the fan with the sticker side facing into the base.

-

M3 x 18mm Bolt

-

M3 Nyloc Nut

-

40mm Fan

-

-

-

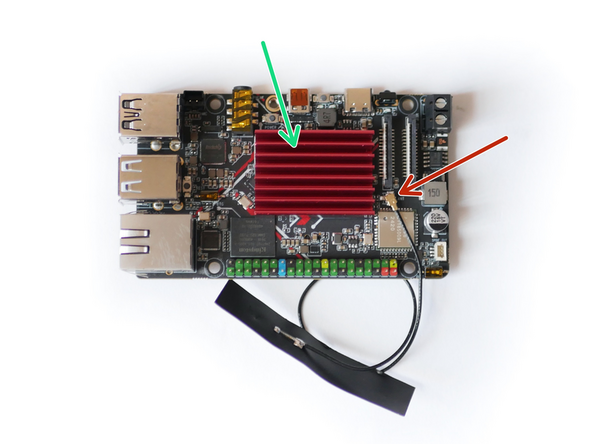

Before unpacking the Pi control board make sure that you have grounded yourself. You can do this by touching a large metal object. This is to prevent any static from damaging the control board when handling it.

-

Connect the WiFi antenna.

-

The connector can be fiddly to install, we recommend lining it up and pressing it down firmly with the end of an Allen key.

-

Stick the heatsink on to the Pi board.

-

-

-

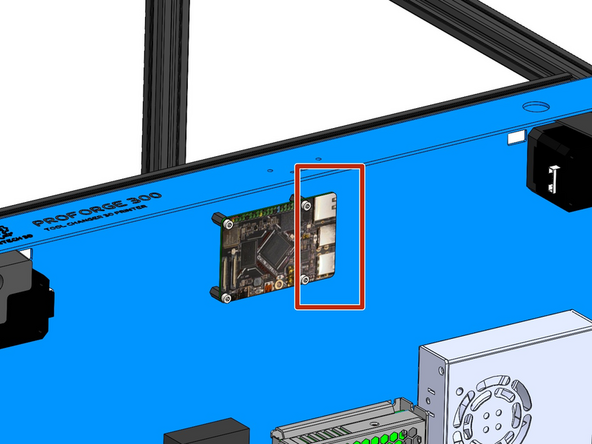

Mount the board to the base:

-

M3 x 6mm bolt (x8)

-

M3 x 10mm standoff (x4)

-

Mount the board with the USB ports pointing to the right as shown.

-

Do not stick the antenna to the base as this may cause signal issues if it is stuck onto metal. Instead leave it hanging.

-

-

-

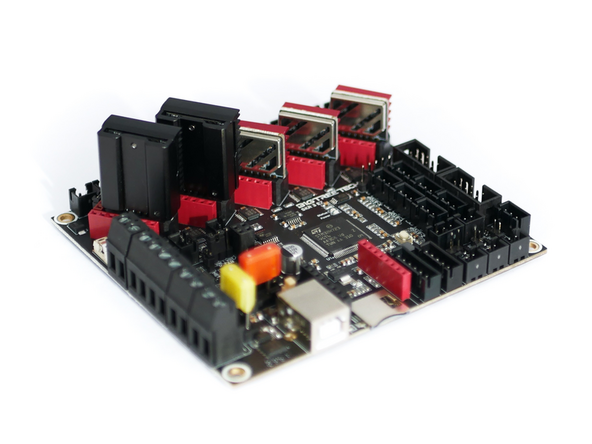

Before unpacking the control board make sure that you have grounded yourself. You can do this by touching a large metal object. This is to prevent any static from damaging the control board when handling it.

-

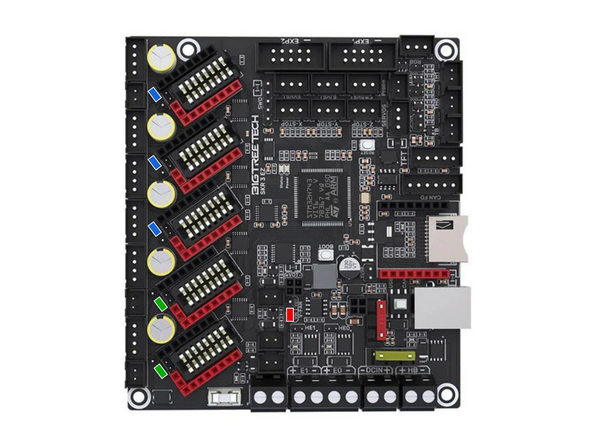

After unpacking the control board you should find a bag of jumpers.

-

For some jumpers may already be mounted onto the board, make sure they are in the correct positions as described below:

-

Use these jumpers to close connections between pins as shown on the diagram.

-

These two jumpers will send 48V to the Gantry Motors

-

These three jumpers will send 24V to the Z-Motors

-

This jumper will send 24V to the SSR Relay for the heated bed.

-

Improper placement of these jumpers will result in damage to the electrical components.

-

-

-

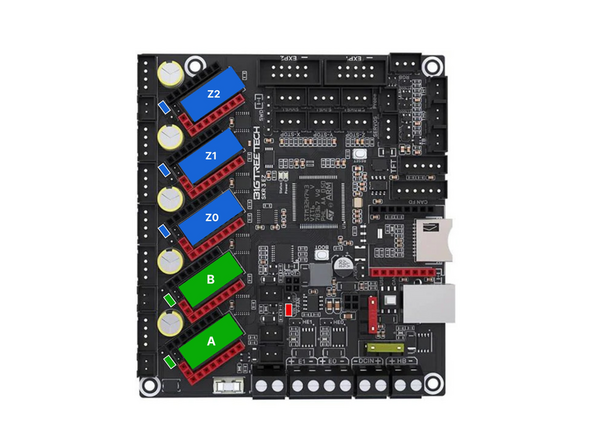

Before unpacking the stepper driver boards make sure that you have grounded yourself. You can do this by touching a large metal object. This is to prevent any static from damaging the drivers when handling them.

-

These drivers can only be plugged in one way round. The flat side of the drivers heatsink should face the screw terminals on the control board.

-

With the board placed on table, carefully push the motor drivers into their slots.

-

Plug two TMC5160 RGB EZ Drivers into the board as shown. They will drive the gantry motors.

-

Plug three TMC2209 EZ Drivers into the board as shown. They will drive the Z motors and extruders.

-

-

-

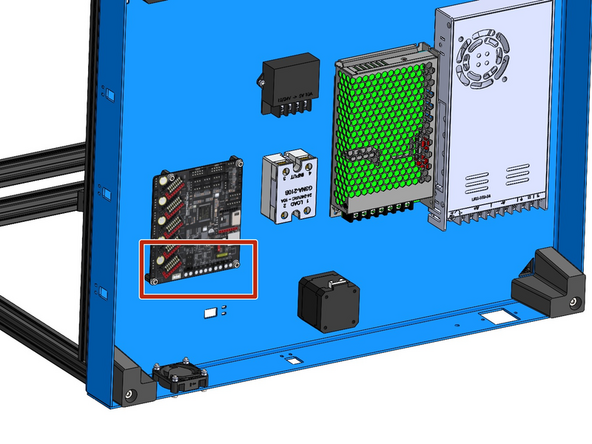

Mount the SKR 3 EZ Control Board as shown:

-

M3 x 6mm Cap Bolt (x8)

-

M3 x 10mm Standoff (x4)

-

Orientate the board with the terminals pointing to the rear of the base.

-

-

-

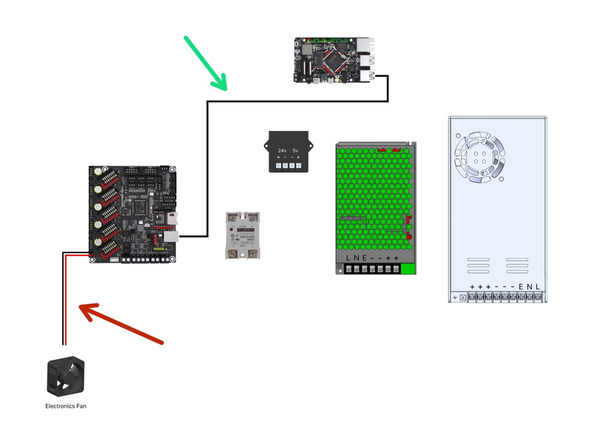

Connect the electronics fan to the SKR control Board.

-

Connect the USB cable from the Pi to the SKR Board.

-

This USB cable should have been included in the box with the SKR Board.

-

-

-

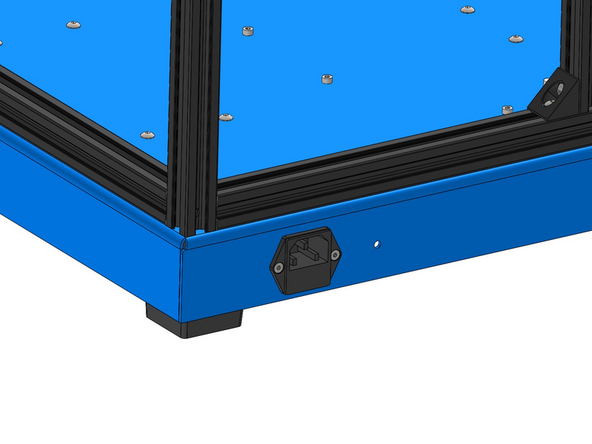

Push all of the cables attached to the power port into the base.

-

Fix the power port to the rear of the base.

-

M3 x 10mm Counter Sunk Bolt

-

M3 Nyloc Nut

-

-

-

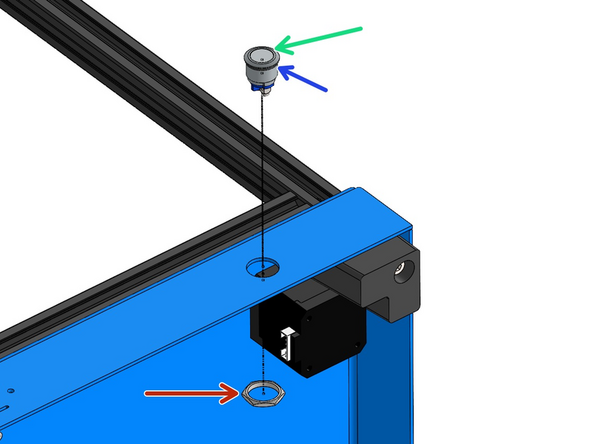

Disconnect the power switch from the power cable assembly.

-

Remove the nut from the switch.

-

Mount the switch to the front of the base as shown, feeding the cables attached to it through the hole.

-

Switch

-

O-Ring

-

Nut

-

Re-connect the switch back to the power cable assembly.

-

-

-

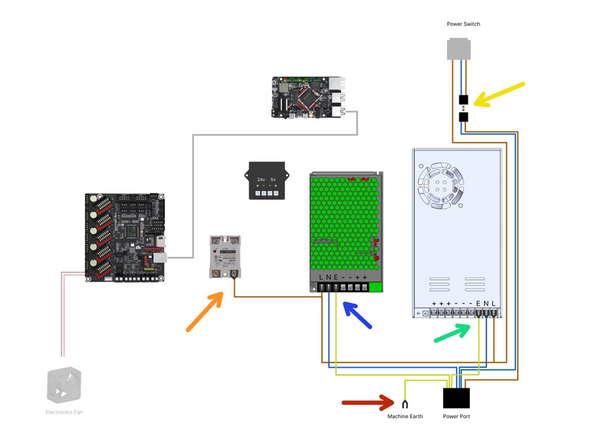

Connect the switch to the mains power port.

-

As shown in the diagram connect the cables from the mains power port to the:

-

24V Power Supply

-

48V Power Supply

-

SSR Relay

-

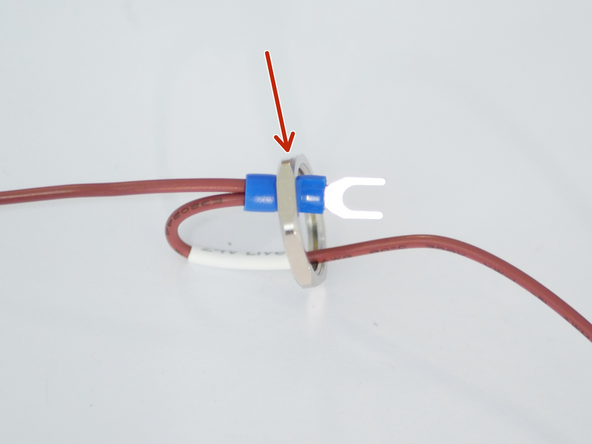

Fix the shortest earth cable to the base where you previously scuffed.

-

M4 x 12mm button bolt and M4 Nyloc Nut

-

-

-

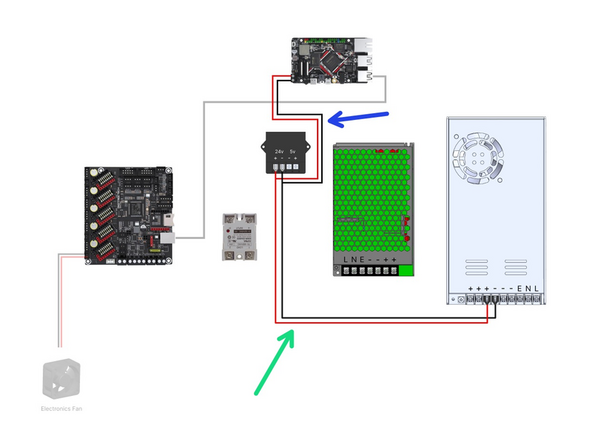

Wire the power converter and BTT Pi as shown.

-

Power Convertor cables - 40cm

-

Connect from 24V PSU to 24V terminals on converter.

-

These cables do not have connectors on the ends, but can still be connected to the terminal without problem.

-

Pi power cables - 40cm

-

Connect from 24v terminals on the convertor to the BTT Pi.

-

-

-

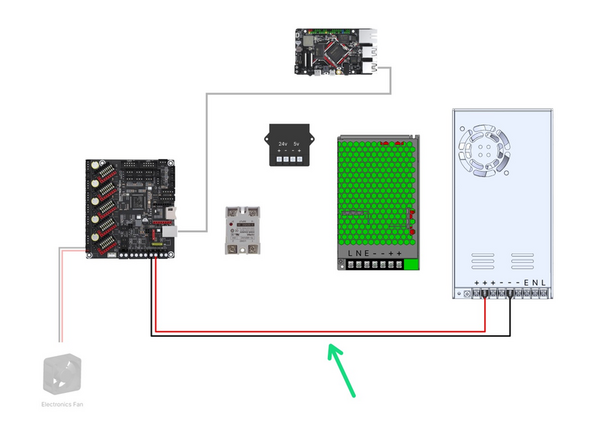

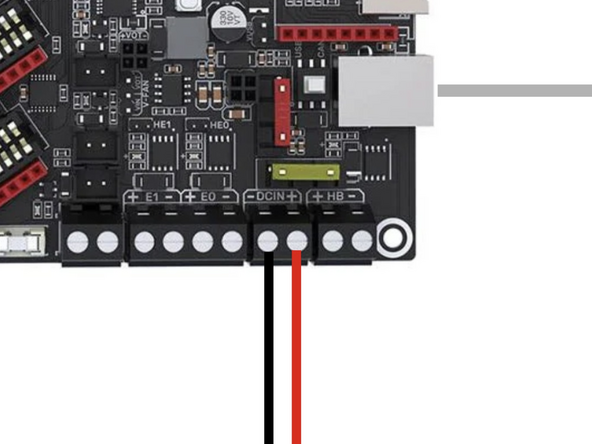

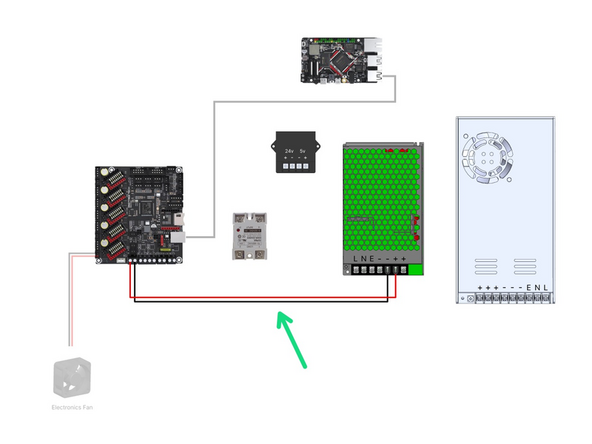

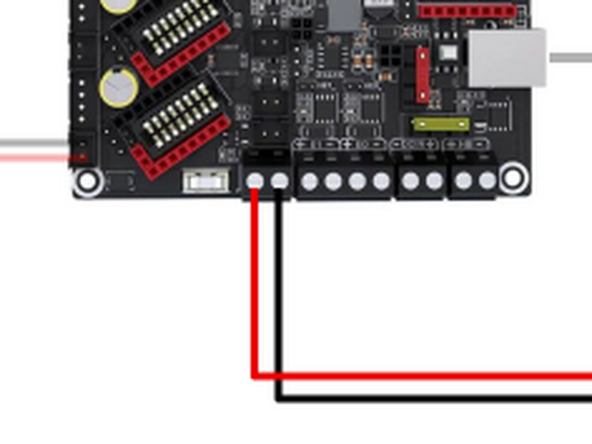

Fix the power cables from the 24v PSU to the control board as shown.

-

Main Board Power Cables - 40cm

-

-

-

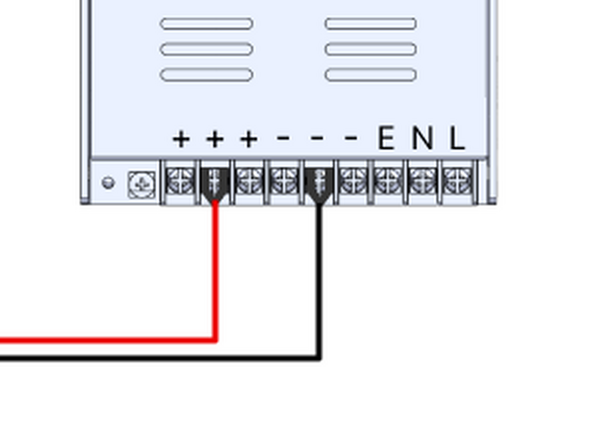

Fix the motor power cables from the 48v PSU to the control board as shown.

-

Motor Power Cables - 40cm

-

-

-

Use the cable tie mounts and cable ties to tidy up the cables.

-

Alternatively you can wait until the end of the build to do this.

-

-

-

Before continuing it's important to double check your wiring. Make sure that the wires are plugged in the right way round, with positive going to positive and negative going to negative.

-

Incorrect wiring may cause your electronics to give off smoke that cannot be put back.

-

Cancel: I did not complete this guide.

2 other people completed this guide.