-

-

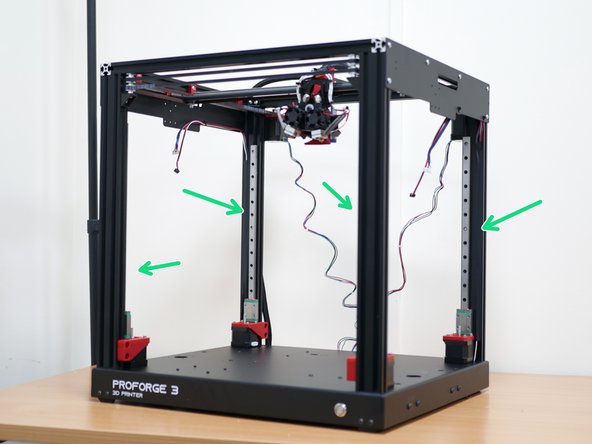

Remove the old motor cables from the frame.

-

Unplug them from the control board also and place them to one side.

-

If you have the Pi cam installed, also remove it and place it to one side.

-

-

-

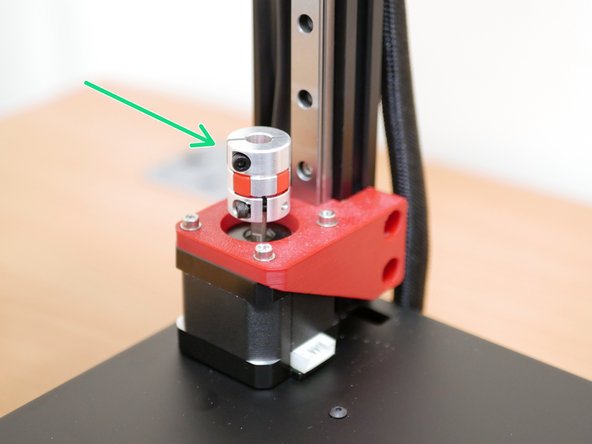

Remove the Z-axis motors from the base and fix them onto the 3D printed Z-motor mounts. Serial No. 42BYGH438.

-

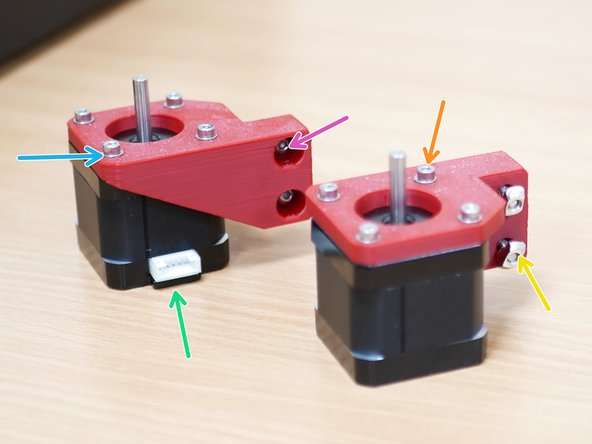

Note, the mounts are mirrored. These two motors will be installed at the front of the base.

-

Orientate the motors as shown with the cable connectors facing away from the mounting holes.

-

M3 x 10mm Bolt

-

M3 Washer

-

M4 x 12mm Bolt

-

M4 T-Nut

-

-

-

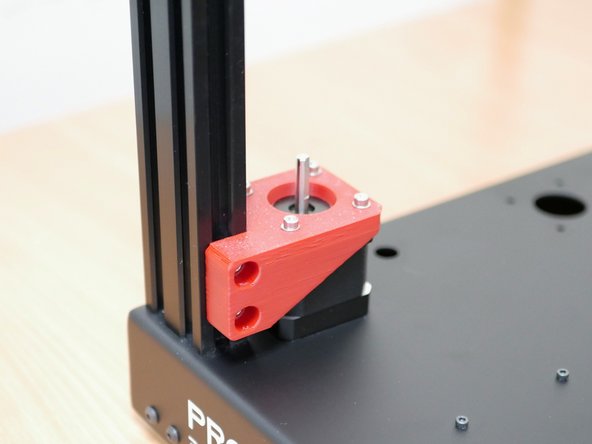

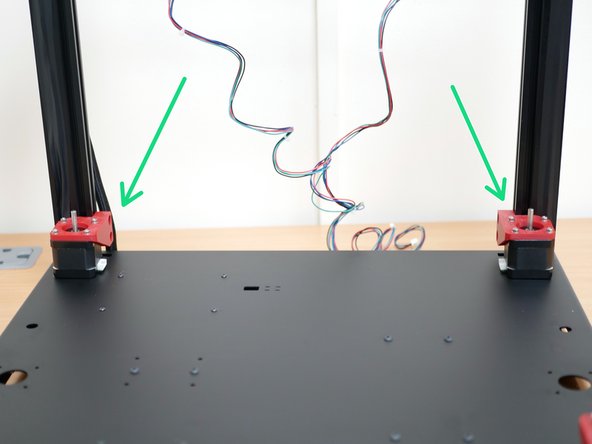

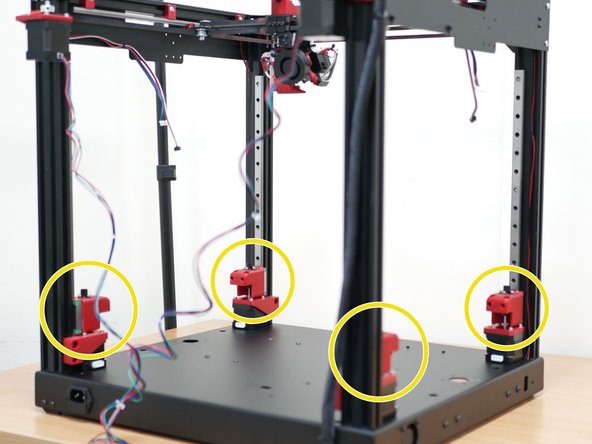

Secure those motor assemblies to the inside front of the frame as shown.

-

-

-

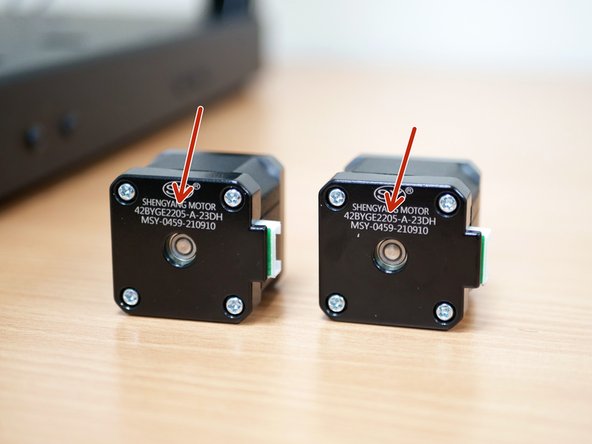

Take the two motors from the old Top Panel Assembly. The motor number should have a 205 in it.

-

As before, the mounts are mirrored. These two motors will be installed at the rear of the base.

-

Orientate the motors as shown with the cable connectors facing the side of the mounting holes.

-

M3 x 10mm Bolt

-

M3 Washer

-

M4 x 12mm Bolt

-

M4 T-Nut

-

-

-

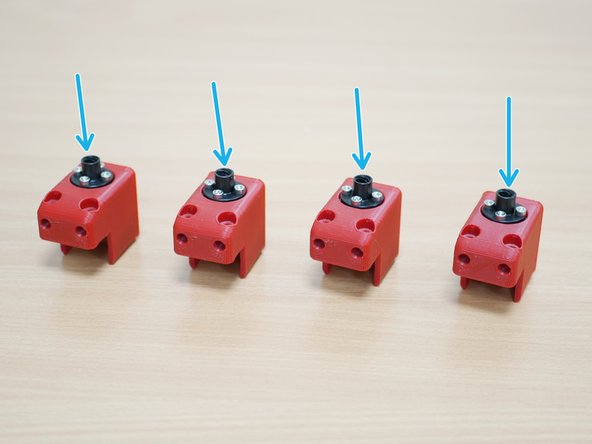

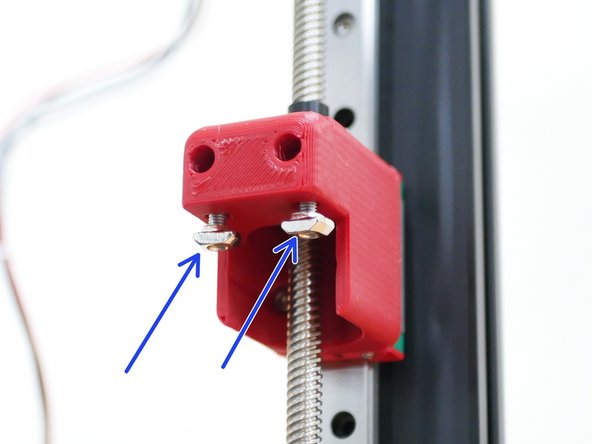

Take the old platform assembly and remove from it the lead screw nuts. The old bolts can be discarded.

-

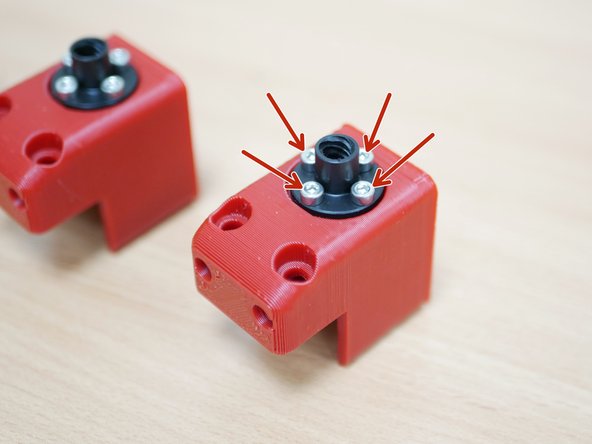

Fix these two lead screw nuts, with the two included in the upgrade kit, to the four 3d printed z-carriage parts.

-

M3 x 10mm Bolt

-

These bolts self tap into the 3d printed part, do not over tighten as it will strip the plastic.

-

-

-

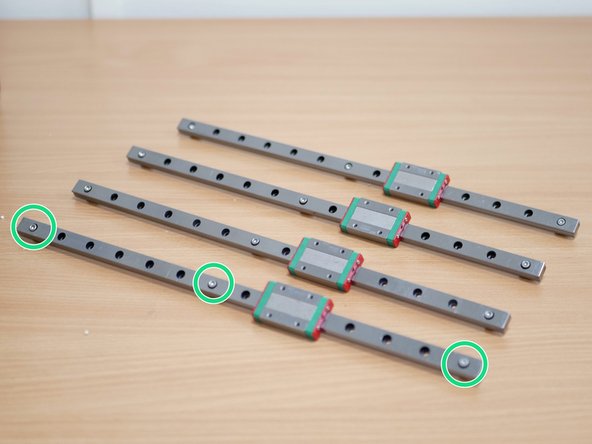

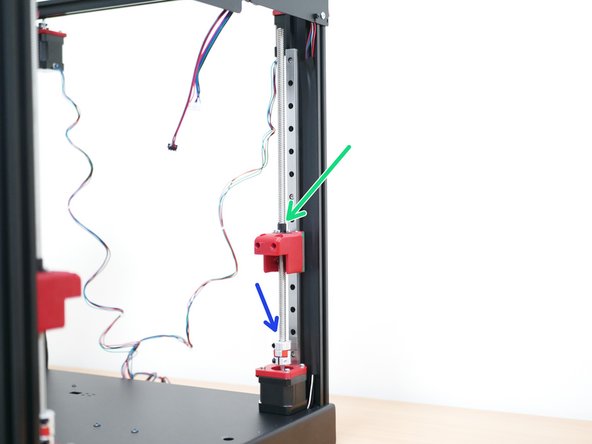

Prepare the linear rails as shown:

-

M3 x 10mm bolt

-

M3 T-Nut

-

Be careful that the carriages do not fall off the rails.

-

-

-

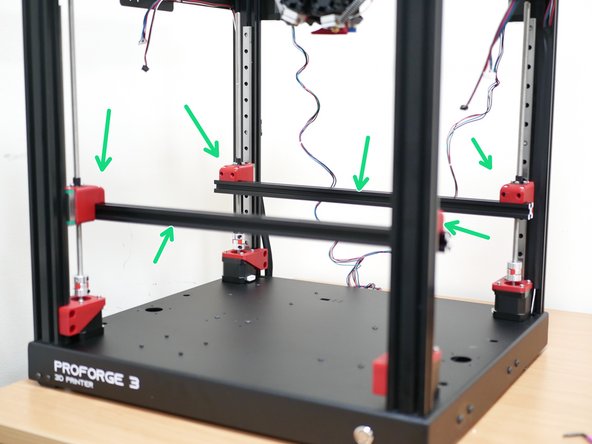

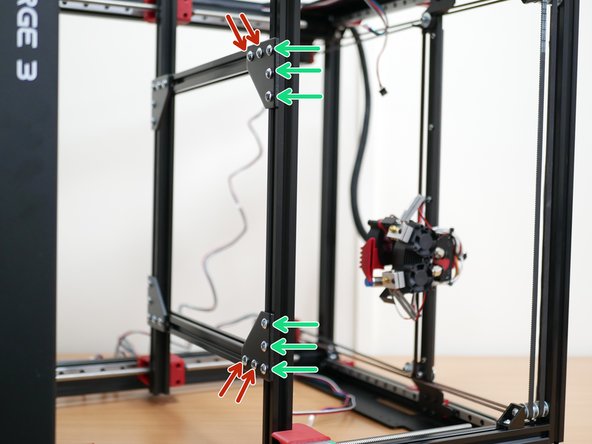

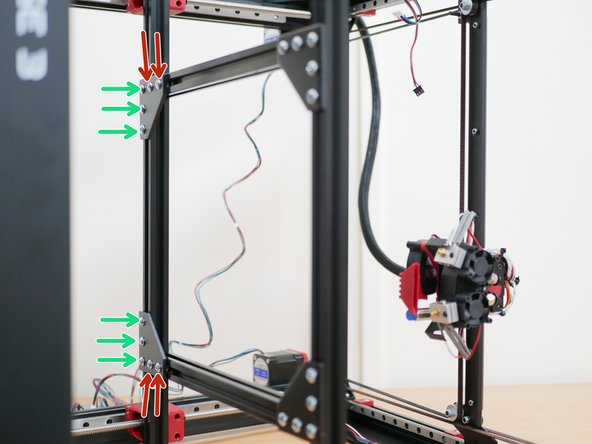

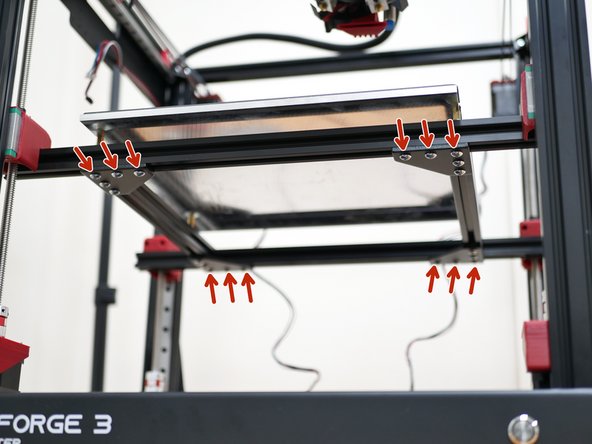

Fix the rails to the inside of the frame as shown.

-

When fixing the rail, press it down on the z-motor mount and then firmly tighten the bolts to the extrusion.

-

-

-

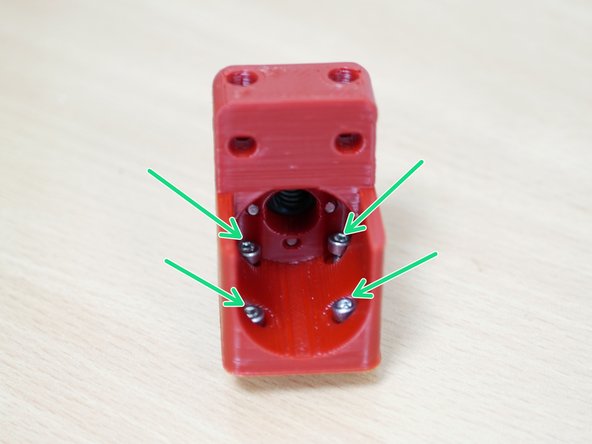

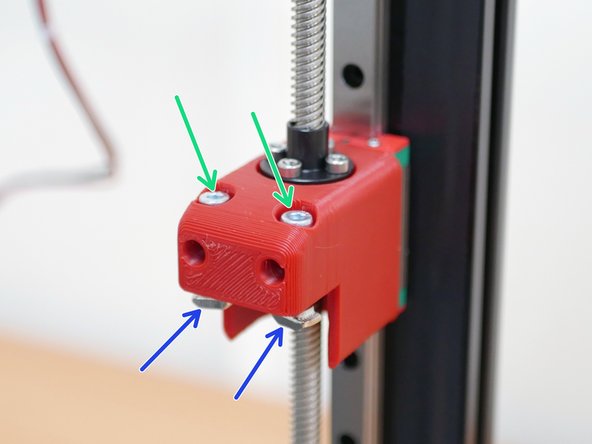

Drop four M3 x 10mm bolts into a Z-carriage as shown.

-

Mount the 3d printed carriage to the rail carriage as shown.

-

Repeat with he other three carriages.

-

-

-

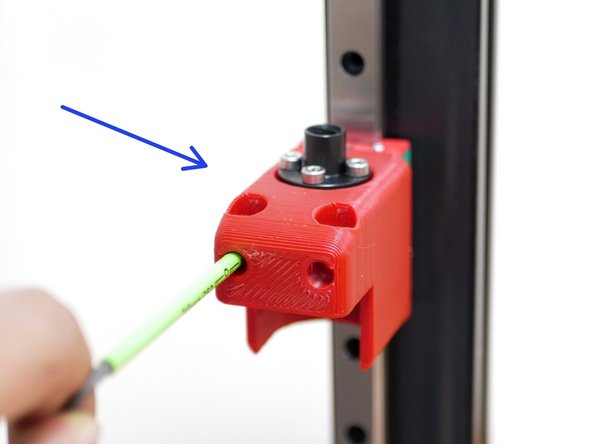

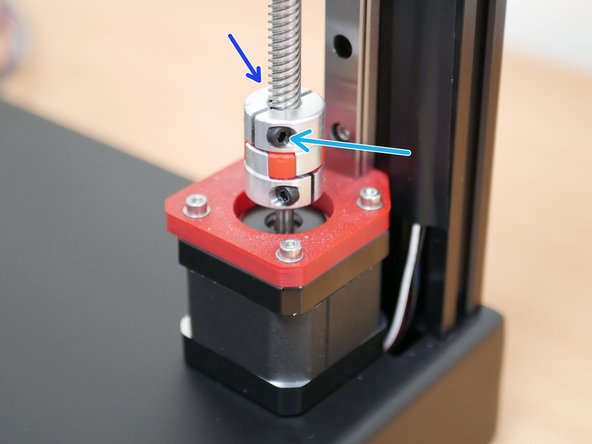

Thread the four lead screws (two form the upgrade and two form the original printer) through the top of the lead screw nut.

-

Feed it into the Plum Coupling.

-

Tighten this bolt to secure it in place.

-

-

-

Drop into each of the Z-carriages two:

-

M4 x 20mm Bolt

-

M4 T-Nut

-

-

-

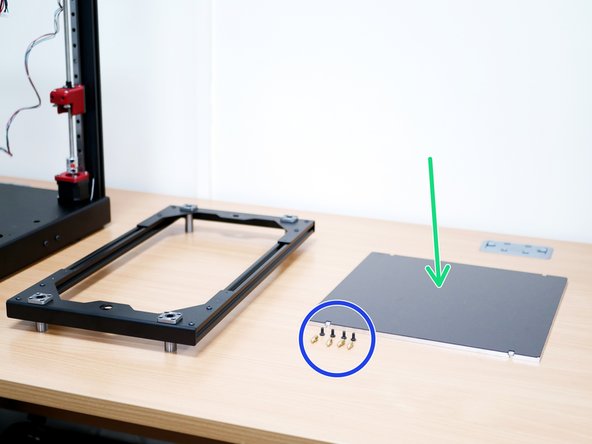

Remove the print platform from the platform frame.

-

Remove the standoffs and M4 bolts - keep these safe as they will be reused.

-

Remove the extrusions from the brackets.

-

These brackets can be discarded.

-

-

-

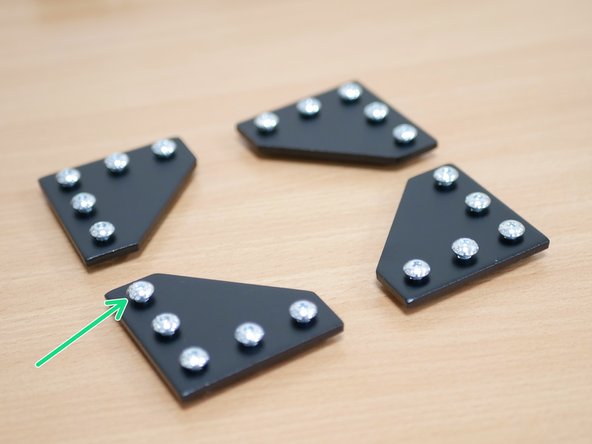

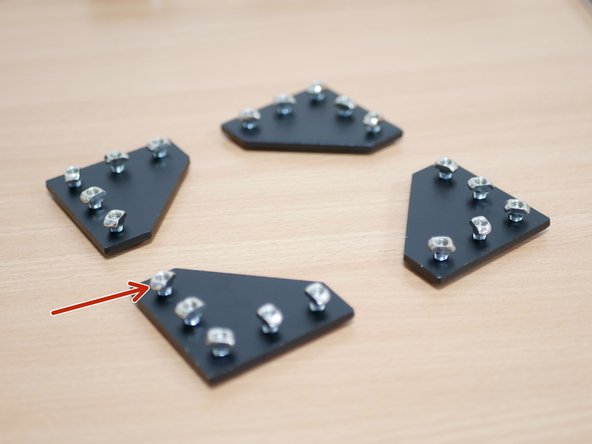

Prepare the four platform brackets as shown with:

-

M5 x 8mm bolts

-

M5 T-Nuts

-

-

-

Use the brackets to join together two shorter extrusions with the two longer ones.

-

The bolts that attach to the shorter extrusions - secure firmly.

-

The bolts that attach to the longer extrusions - secure loosely so that the shorter extrusions can still slide.

-

-

-

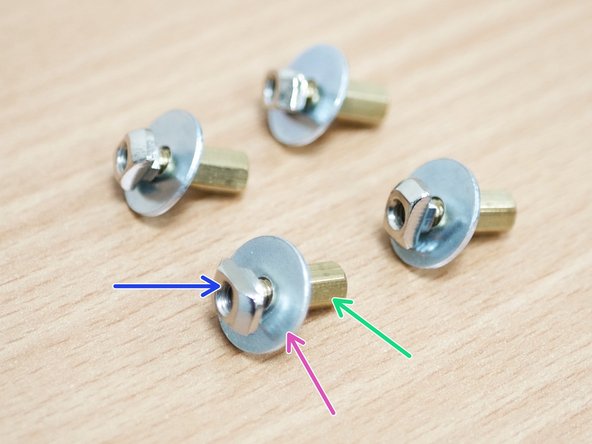

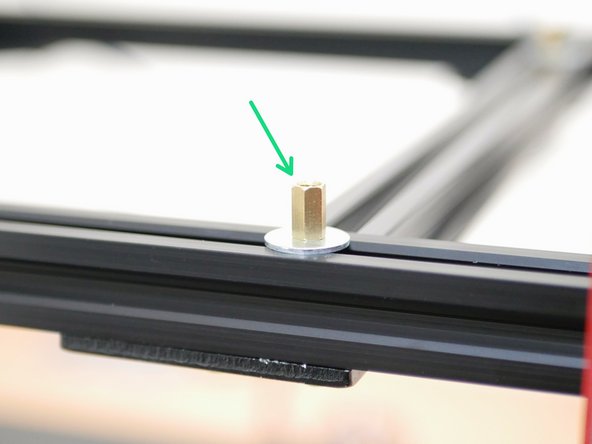

Use the brass stand offs from the old assembly and create four of these assemblies as shown

-

M4 Penny Washer

-

M4 T-Nut

-

-

-

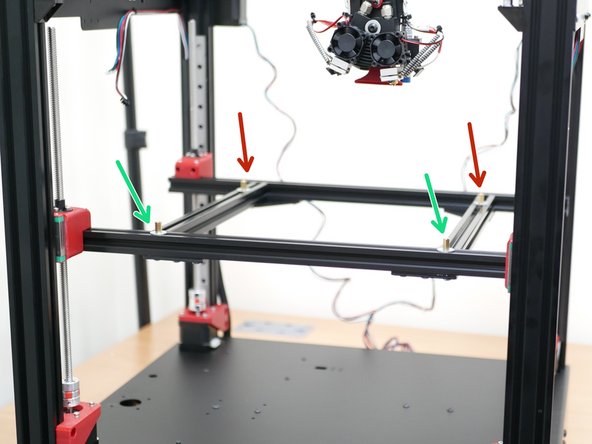

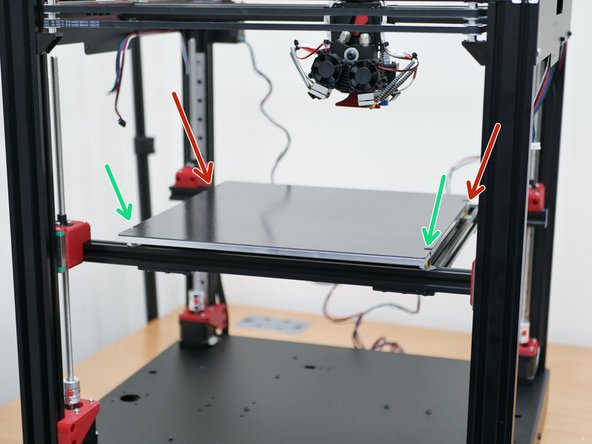

Loosely fix the platform mounts to the extrusions.

-

Position the front two on the longer front extrusion.

-

Position the other two on the sorter extrusions.

-

-

-

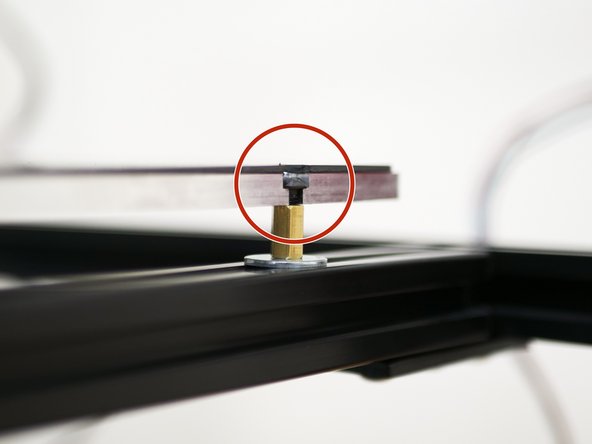

Mount the platform using the old M4 x 6mm bolts.

-

Firmly tighten the rear bolts and hence the mounts to the shorter extrusions,

-

Loosely fasten the front two bolts, so that the platform can still slide left and right.

-

-

-

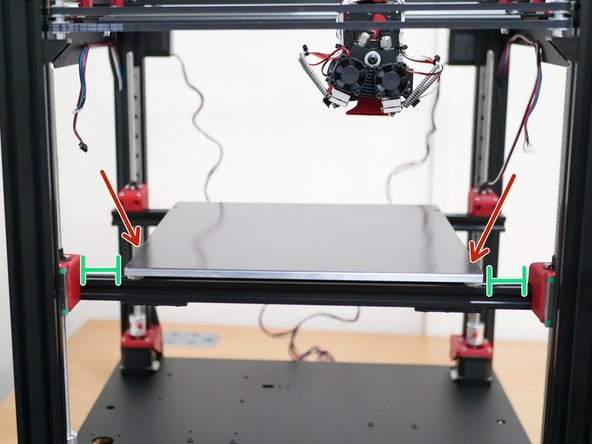

With the platform still able to slide left and right, adjust its position so that it lines up to the centre of the printer.

-

The distance between the edge of the platform and the 3d printed carriage should be approx. 47mm.

-

When happy it is approximately central, tighten down the remains loose bolts:

-

Front platform bolts

-

Bracket bolts

-

Cancel: I did not complete this guide.

4 other people completed this guide.