-

-

Prepare 12 rail mounts as shown by loosely fastening a T-nut onto the M5 bolt.

-

M5 x 8mm Button Head

-

M5 T-nut

-

-

-

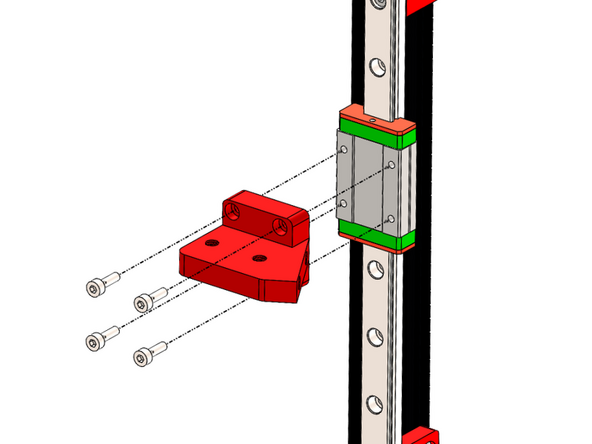

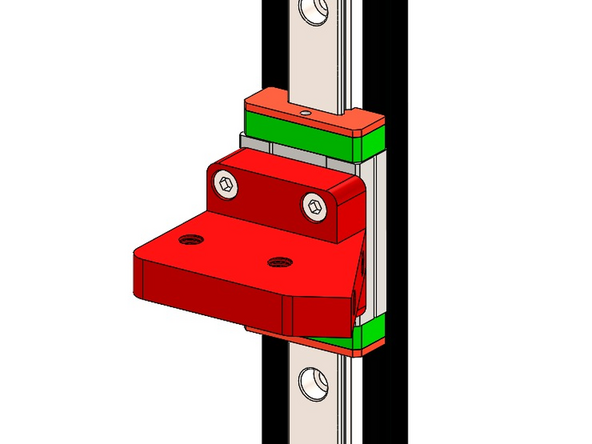

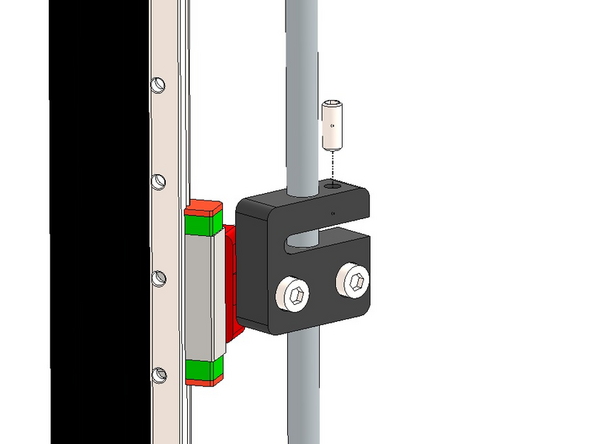

Fix the mount assemblies from the previous steps onto the four 460mm long MGN12 rails.

-

Space them out as shown with two fixed one forth edge and the third in roughly the middle.

-

M3 x 6mm Cap Bolt

-

Use the orange stoppers to prevent the carriage from falling off the rail.

-

-

-

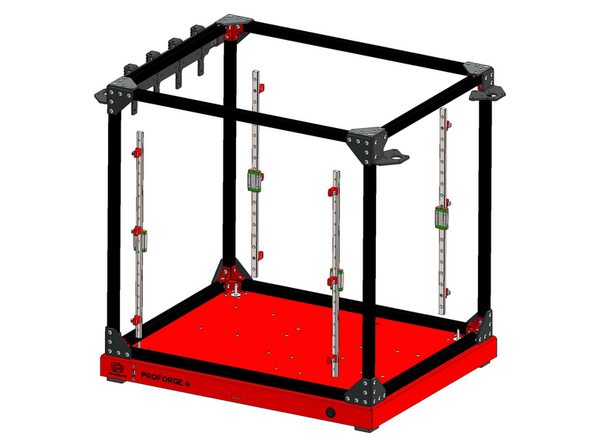

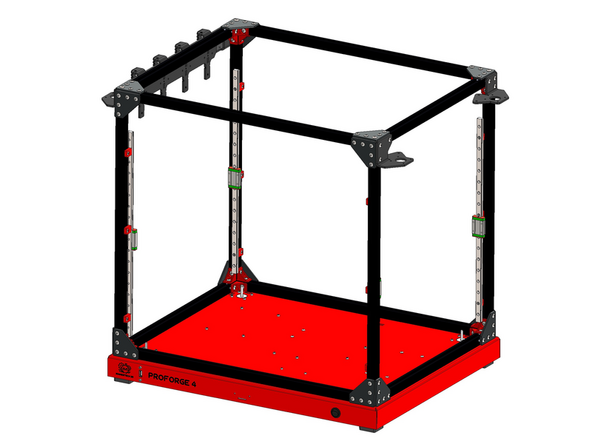

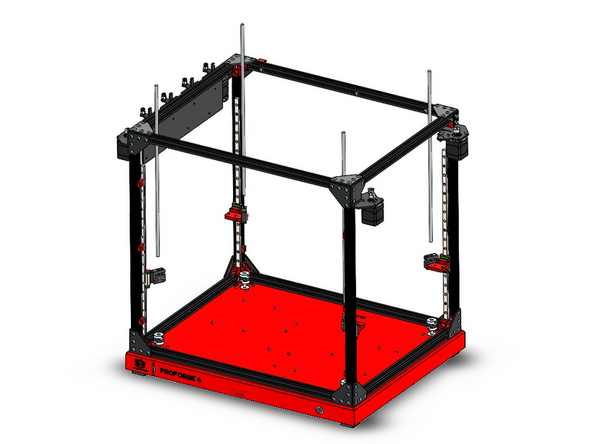

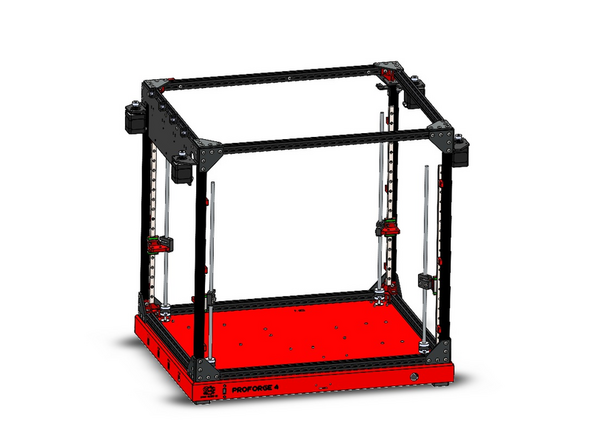

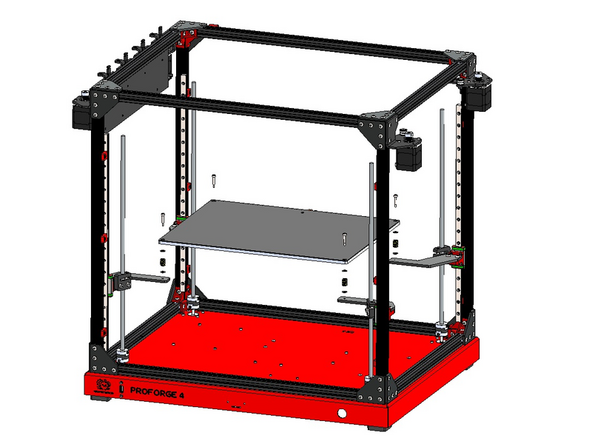

Mount the rail assemblies onto the inside of the frame as shown.

-

Mount the rail assemblies onto the inside of the frame as shown.

-

-

-

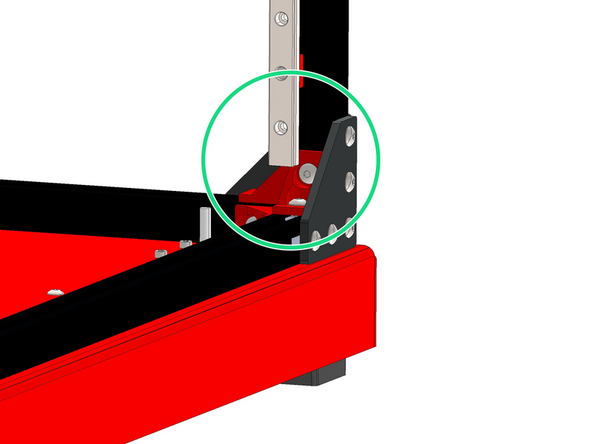

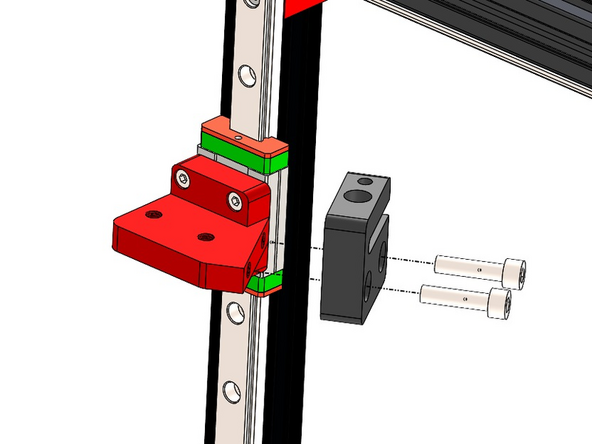

Mount the four Z-Carriages onto the rail carriages.

-

P4.2 Z-Carriage

-

M3 x 10mm Cap Head Bolt

-

Match the orientation of the brackets as shown.

-

-

-

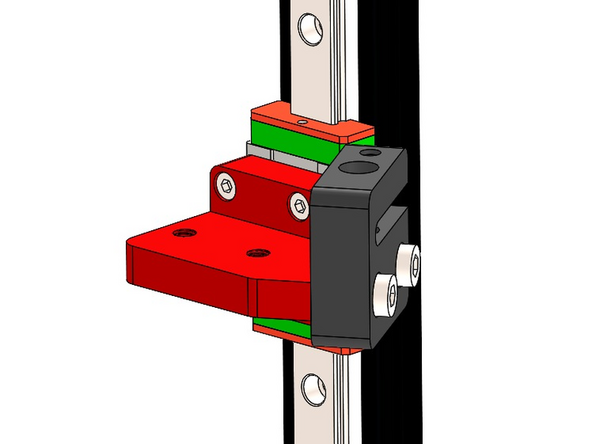

Fix the lead screw nut onto the bracket.

-

M5 x 20mm Bolt (Button head - image is incorrect)

-

Orientate the nut as shown.

-

-

-

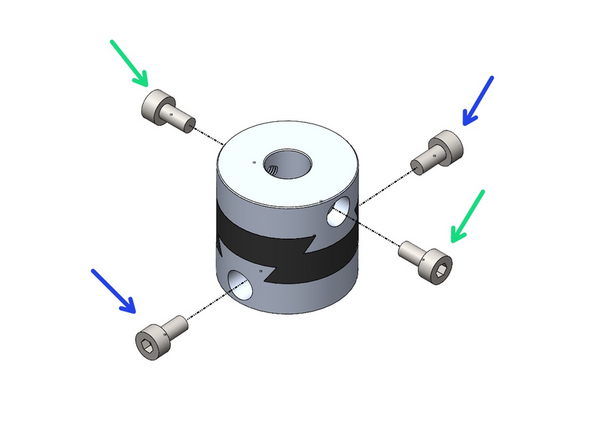

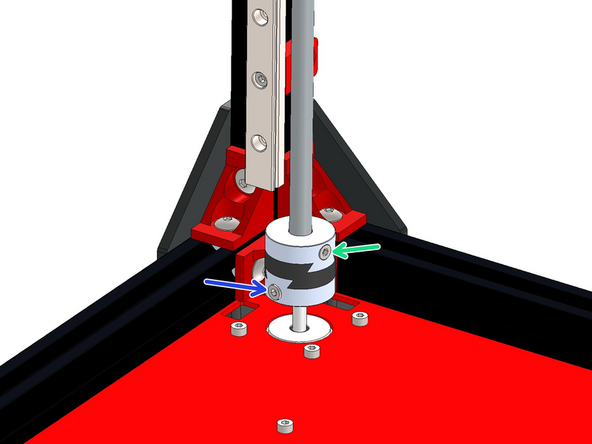

Assemble four Oldham Couplings as shown.

-

M3 x 6mm Cap Head Bolts

-

M3 x 8mm Cap Head Bolts

-

-

-

Install the Oldham couplings to the Z-Motors shafts and Lead Screws.

-

-

-

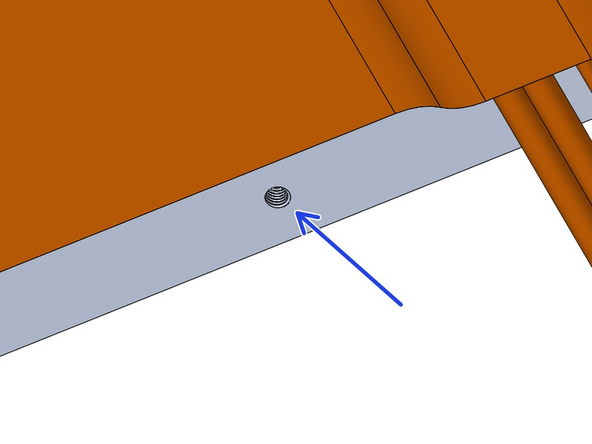

Add the M5 x 12mm Grub screw to the lead screw nut as shown.

-

Tighten until you feel some resistance, the purpose of this grub screw is to prevent backlash along the nut and lead screw.

-

Do not tighten to the point that the lead screw will no longer turn. You should still have smooth rotation of the lead screw through the nut.

-

-

-

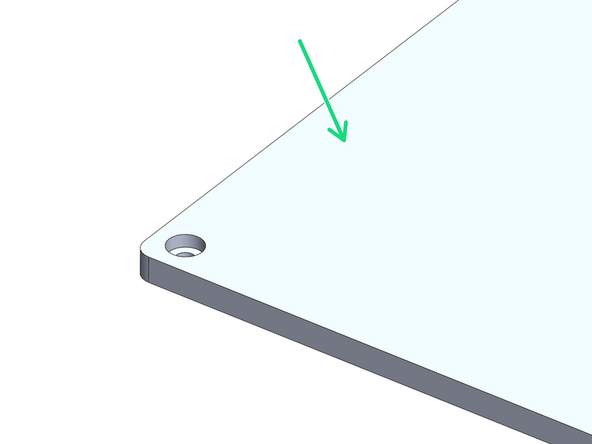

Stick over the aluminium platform plate the magnetic flex-plate sticker.

-

You may find this sticker, being magnetic, stuck onto the back of the black PEI flexplate in the packaging.

-

Ensure it is stuck onto the side shown in the images.

-

Peel away the backing paper from the magnetic sheet. Begin by sticking it to one of the shorter edges pressing it down carefully preventing any air bubbles. Use a credit card to press the sticker down, pushing out any potential air pockets.

-

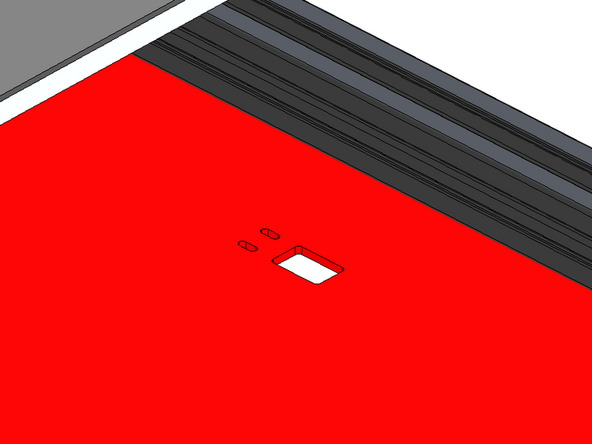

After sticking the sheet down use a craft/box knife to cut away where shown to expose this hole. Use a pin to poke through the other side of the plate to make where you should cut. This is where the calibration probe mounts to.

-

You don't need to be particularly neat about these cuts, this sticker will have the flexplate go over it.

-

-

-

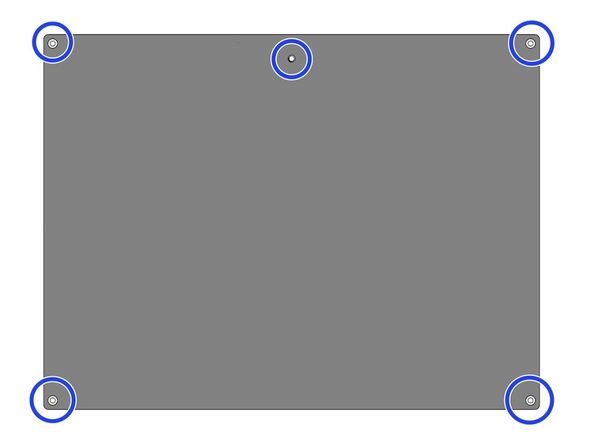

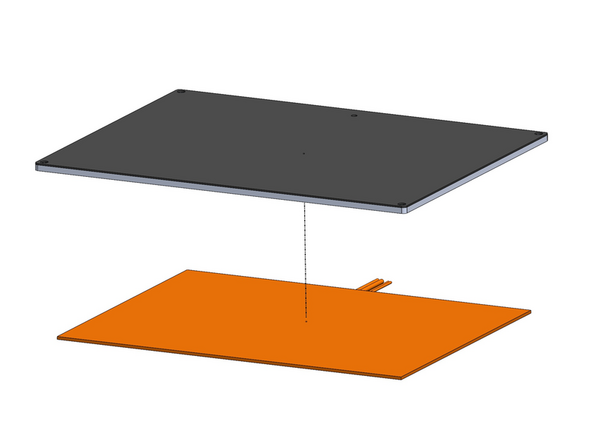

Peel the backing paper away from the heater pad.

-

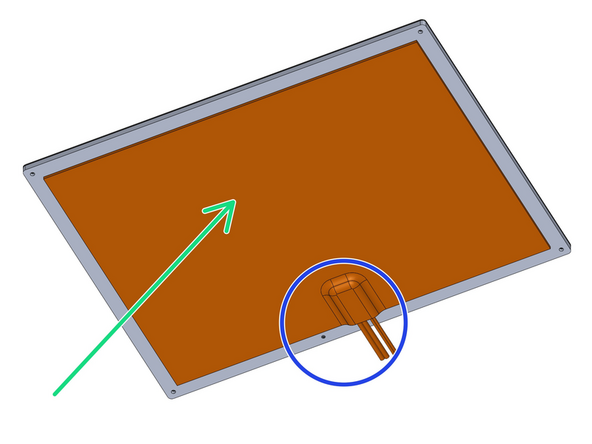

Fix the heater onto the centre of the underside of the platform as shown.

-

Ensure the cables are on the side with the M4 threaded hole as shown.

-

Make sure the hole is not covered either.

-

-

-

Fix the 1M Earth cable to the platform with an M4 x 6mm button head bolt.

-

-

-

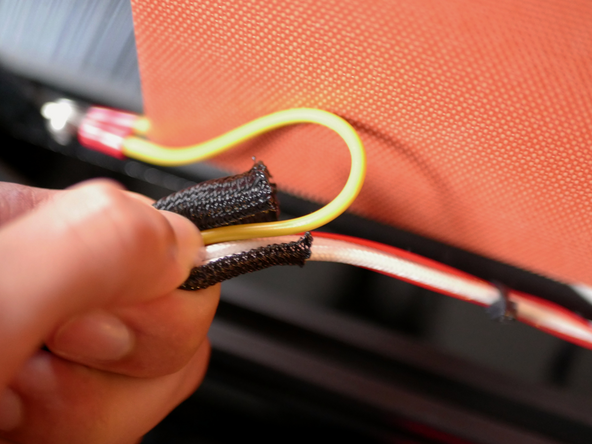

Cut 70cm of the braided sleeving and wrap the heater and earth cables with it.

-

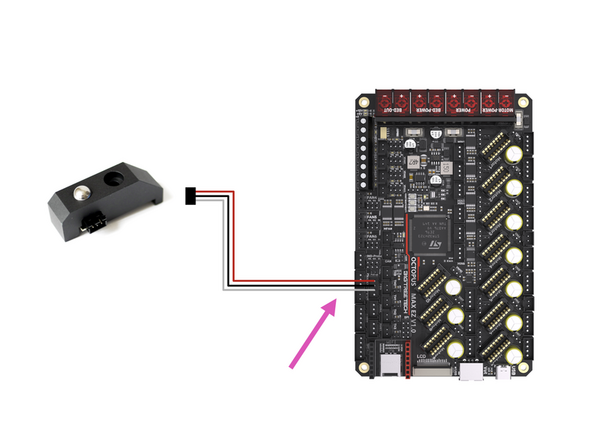

Also wrap into this cable sleeving the black, white and red cable for the calibration probe. Ensure that the side of the cable with the 3-pin header is on the side of the heater.

-

-

-

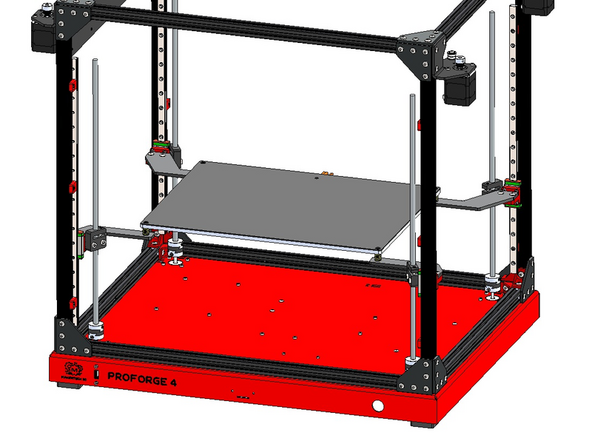

Mount the four Z-Brackets to the Z-carriages as show.

-

The larger brackets go to the rear of the printer.

-

Fix with two M5 x 14mm Button Head Bolts.

-

-

-

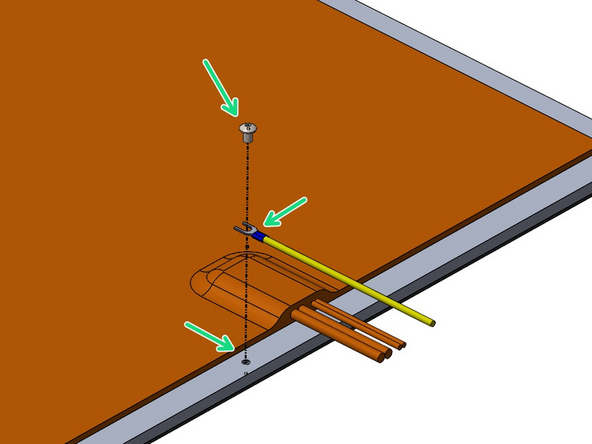

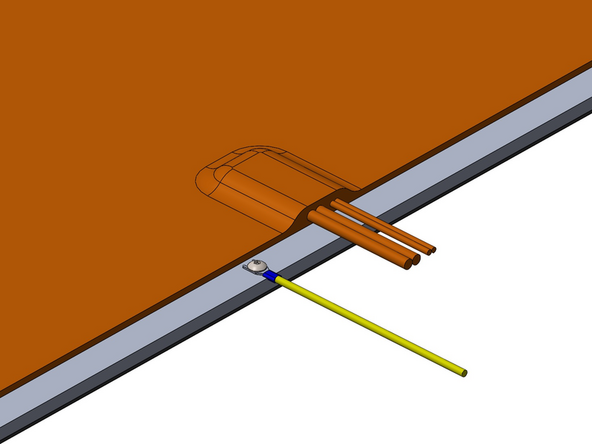

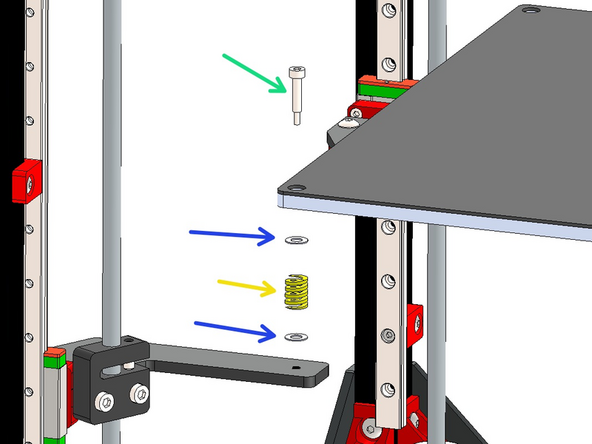

Mount the platform assembly onto the Z-Brackets:

-

M3 x 16mm Shoulder Bolt

-

M4 x 8 x 0.5mm Shim

-

Yellow Compression Spring

-

-

-

Stick onto the underside of the rear left bracket two cable tie mounts.

-

Cable tie the cables from the heater to the cable tie mounts.

-

-

-

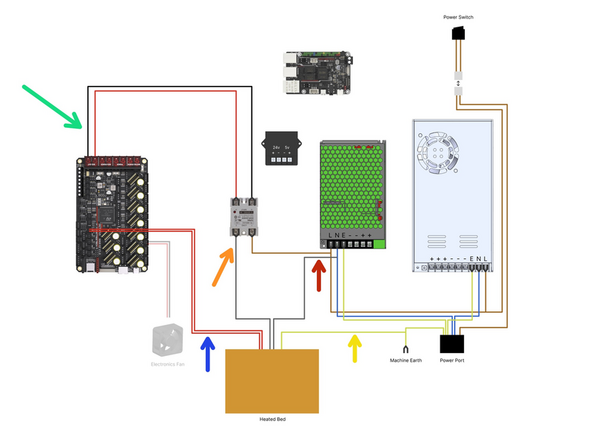

Feed the cables into the base and wire the heated bed as shown:

-

Bed Signal Cables - 30cm

-

Bed Power Cables

-

One cable to SSR Relay

-

One cable to N terminal on 48v PSU

-

Bed Thermistor - Plug into control board

-

Bed Earth - Bolt to Base

-

Calibration Probe Cable - 4-pin connector side (Note that the calibration probe itself is not secured anywhere yet - it is only mounted to the bed when a calibration needs to be performed)

-

Cancel: I did not complete this guide.

One other person completed this guide.