Parts

No parts specified.

-

-

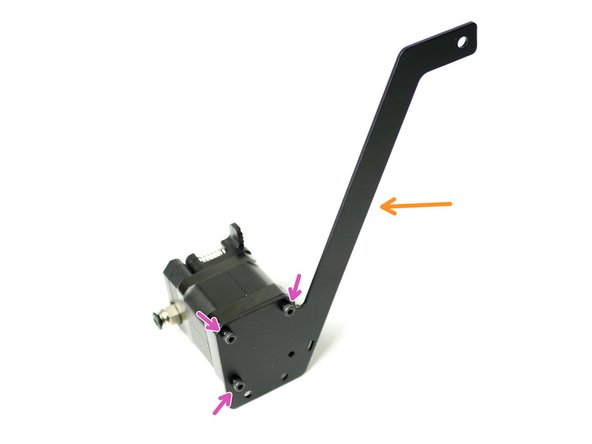

Fix the back plate to the motor face.

-

M3 x 6mm bolt

-

Match the orientation of the motors connector.

-

-

-

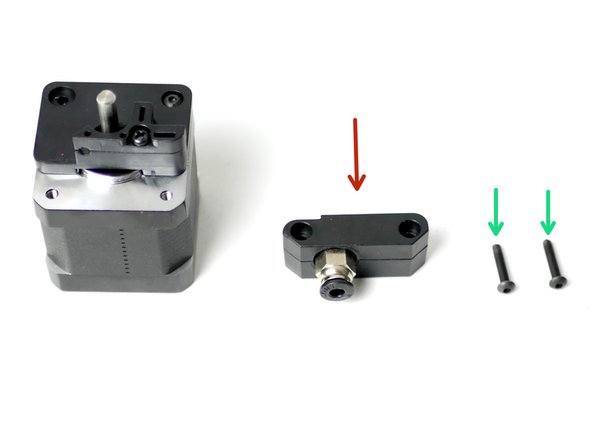

Fix the coupling mount to the face of the motor.

-

Coupling mount

-

M3 x 16mm bolt

-

-

-

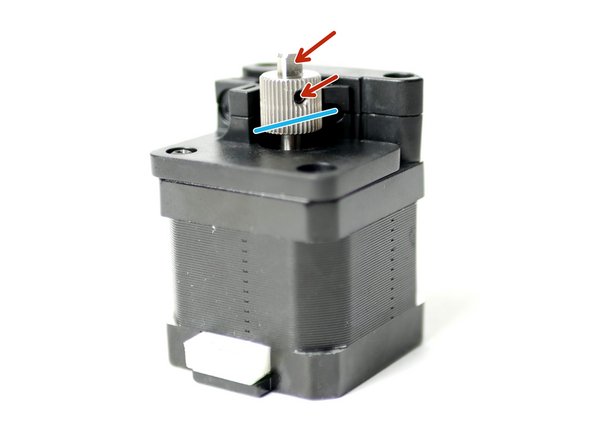

Align the drive gear so that it runs with the filaments path.

-

Filament path

-

Fix the Drive Gear to the shaft of the motor.

-

Tighten the set screw onto the flat of the shaft. Tighten firmly.

-

-

-

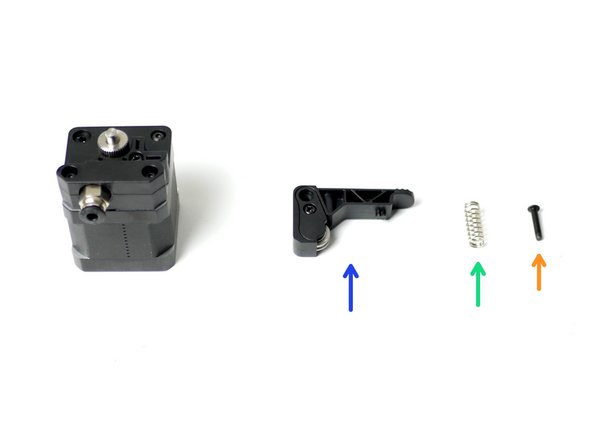

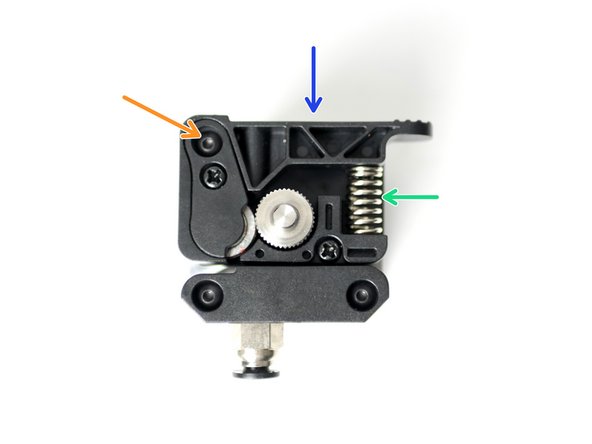

Take the Idler arm and attach it to the assembly.

-

Idler arm

-

Extruder Spring

-

M3 x 16mm bolt

-

Put the spring in place and hold the arm in position before dropping in the M3 x 16mm bolt.

-

Do not over tighten, the arm should still be able to swivel when pressure is applied.

-

-

-

Take three M3 x 40mm bolts and slide onto each of them an M3x2mm spacer.

-

M3 x 40mm bolt

-

M3 x 2mm spacer

-

Fix these bolts onto the spool holder and fasten them into the back of the extruder motor, where the three bolts were removed in the previous step.

-

Spool Holder

-

M3 x 40mm bolt and spacer

-

Match the orientation of the spool holder shown.

-

-

-

Create the spool holder arm:

-

M5 x 100mm bolt

-

M5 penny washer

-

M5 nyloc nut

-

Approx 1CM

-

Fix the arm onto the spool holder bracket with another M5 nyloc nut.

-

Make sure that it is on the same side as the extruder.

-

-

-

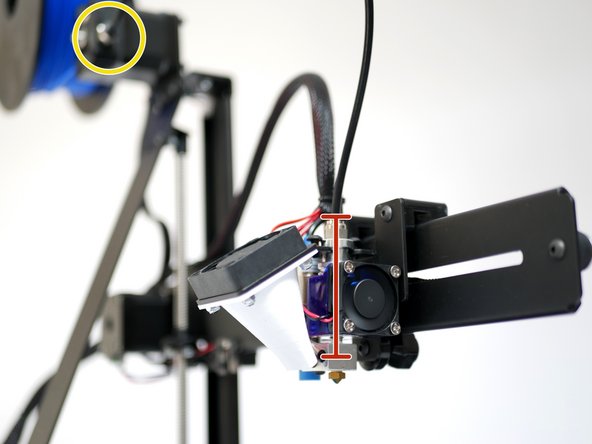

Mount the Extruder assembly onto the left the of the Z-pillar.

-

M4 x 10mm bolt

-

M4 nyloc nut

-

-

-

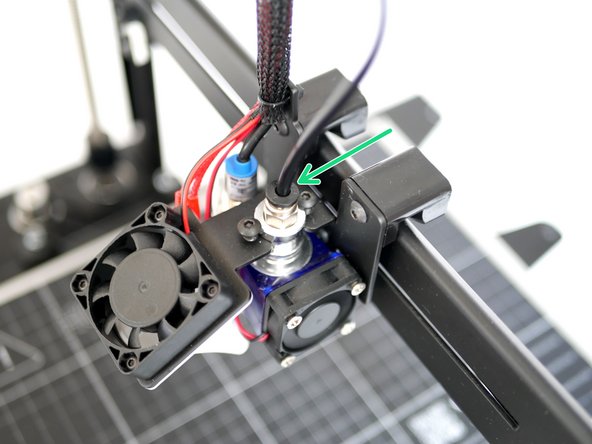

Insert one end of the PTFE tubing to the extruder.

-

Insert the other end into the Hotend.

-

Make sure that it is fed all the way to the bottom of the hotend, this should be approximately 6CM.

-

Double check, as running filament through the hotend with the PTFE tube not all the way down will clog the Hotend.

-

If your hotend does get clogged you will have to disassemble it to remove the clogged plastic from the hotend throat.

-

Cancel: I did not complete this guide.

18 other people completed this guide.

2 Comments

We’d recommend getting up and running with single extrusion first.

The dual extrusion guide is here: