Parts

No parts specified.

-

-

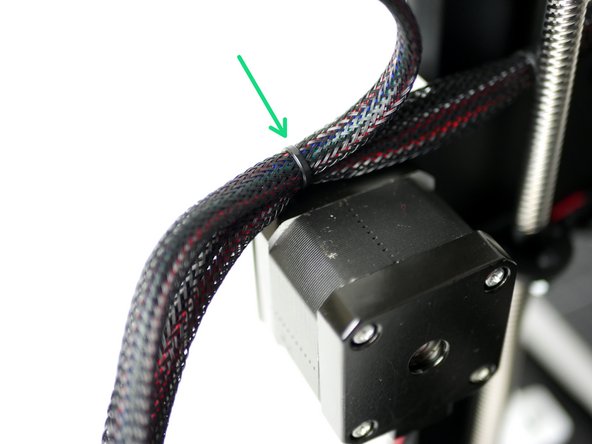

Cut 70CM of the braided cable sleeving.

-

Use a lighter to melt the ends to prevent fraying.

-

-

-

Take two 1m motor cables.

-

Thread the sleaving over both of them.

-

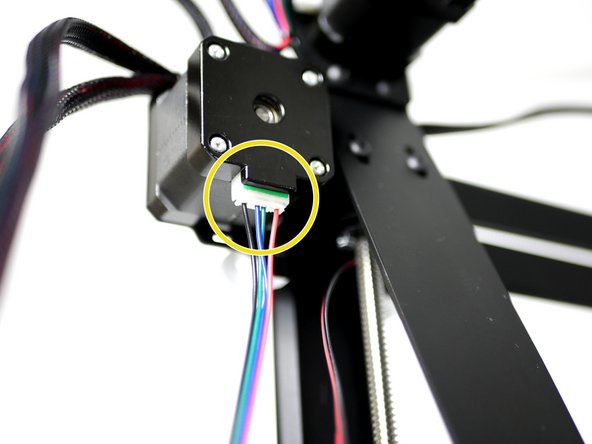

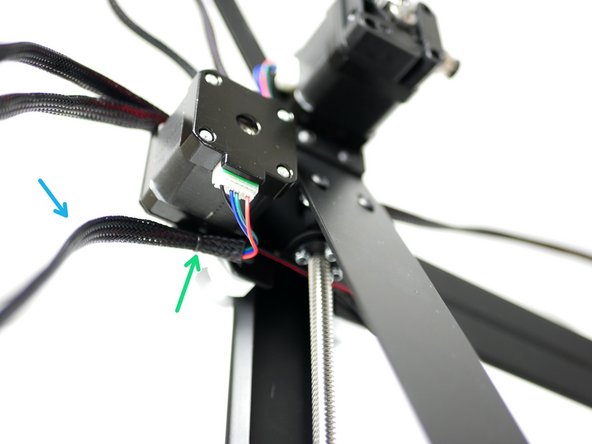

Plug one of the cables into the extruder motor.

-

Cable tie that cable to the spool holder bracket.

-

Note, the second cable is there for the dual extrusion upgrade, it is installed now even if you don't have that upgrade.

-

-

-

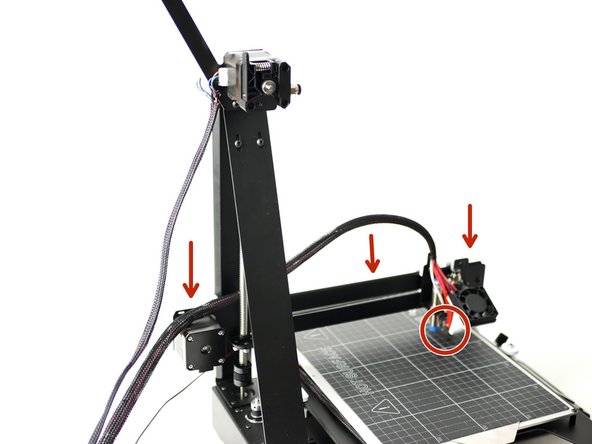

Turn the lead screw to bring the gantry all of the way down, the hotend should be touching the print surface.

-

Cable tie both bunches of cables together to the gantry.

-

-

-

Cut 45CM of the braided cable sleeving.

-

Use a lighter to melt the ends to prevent fraying.

-

-

-

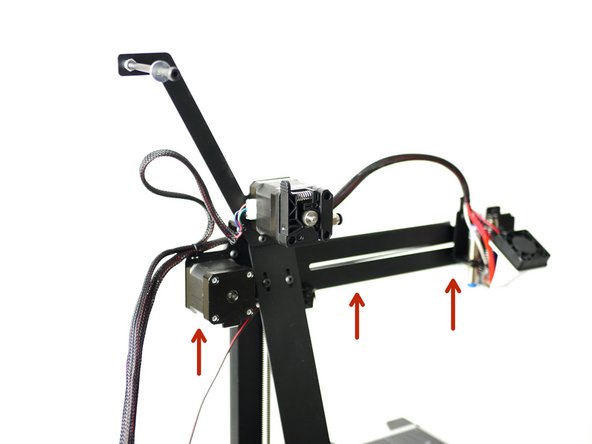

Raise the gantry to the very top.

-

Plug a 1M motor cable into the y-motor.

-

Slide the 45CM cable sleeving over the motor cable and Y-endstop.

-

Cable tie to the bottom of the gantry.

-

-

-

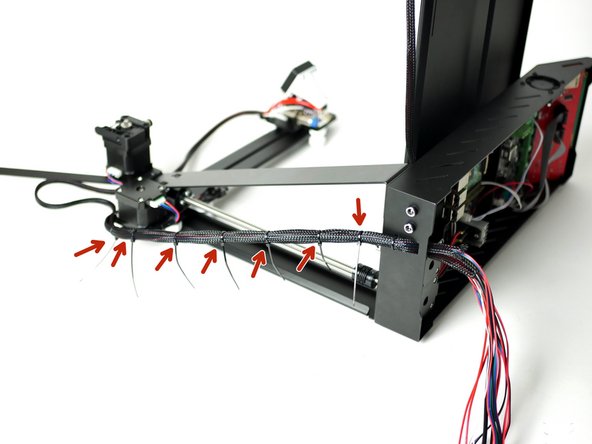

Before tying off the cables together, it may be worth using tape to mark what each of the cables is connected to.

-

Place the Axis on its side like shown. Use multiple cable ties to create a single branch of cable.

-

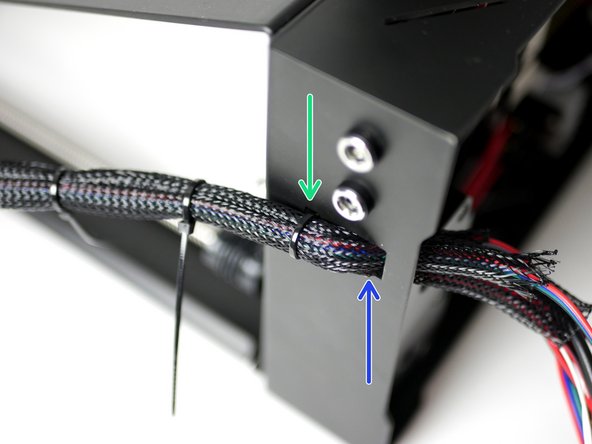

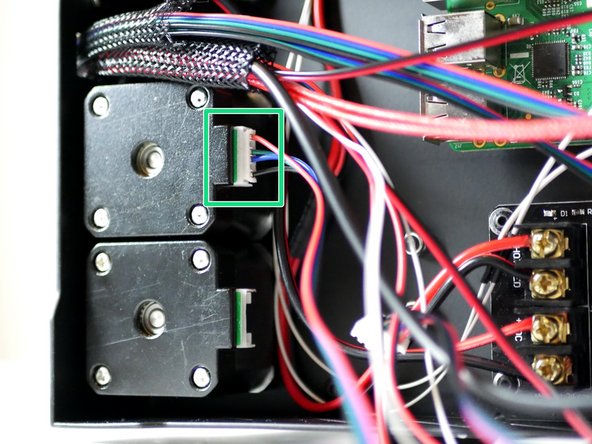

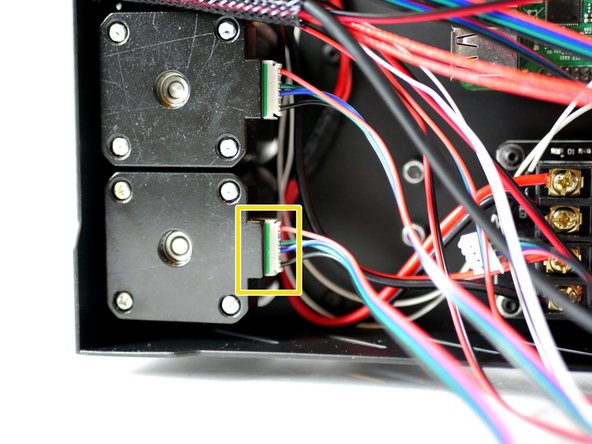

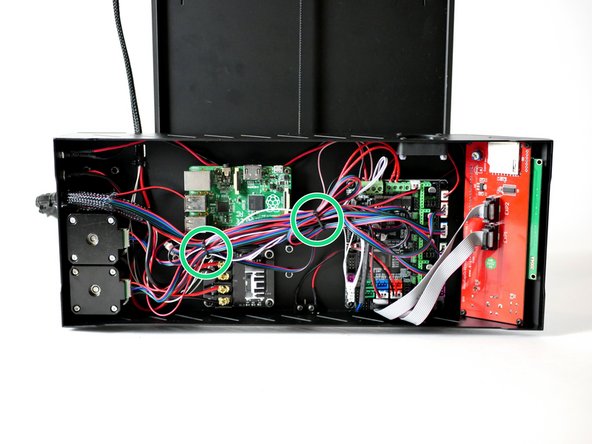

Push all of the cables through the square hole in the back of the base.

-

Use a cable tie to attach the cable branch to the base.

-

-

-

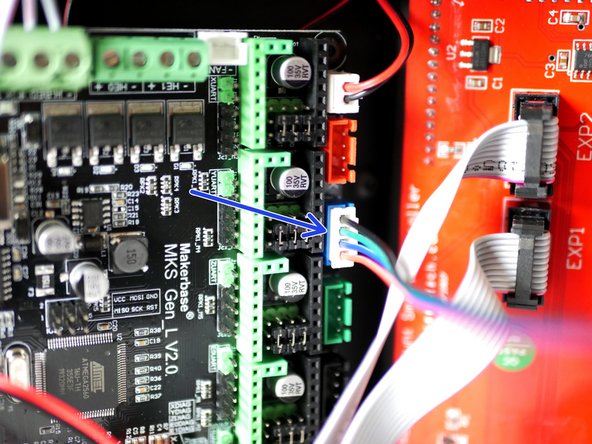

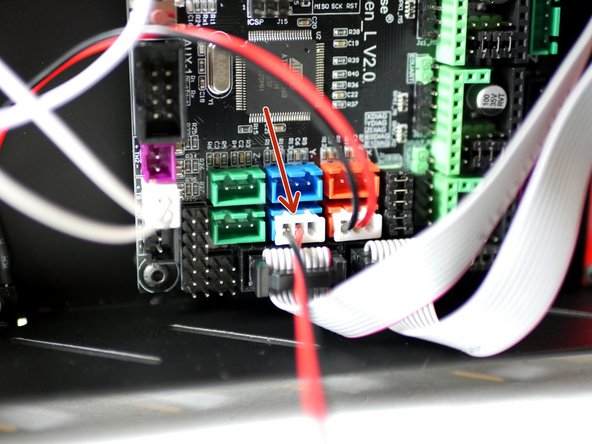

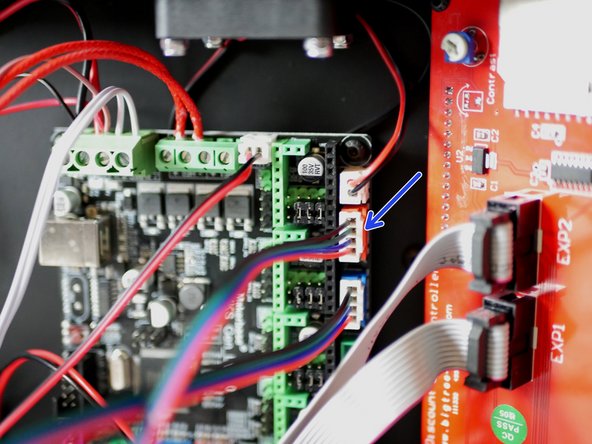

Plug the Y-axis (gantry) motor into the control board.

-

Plug the Y-endstop into the control board.

-

-

-

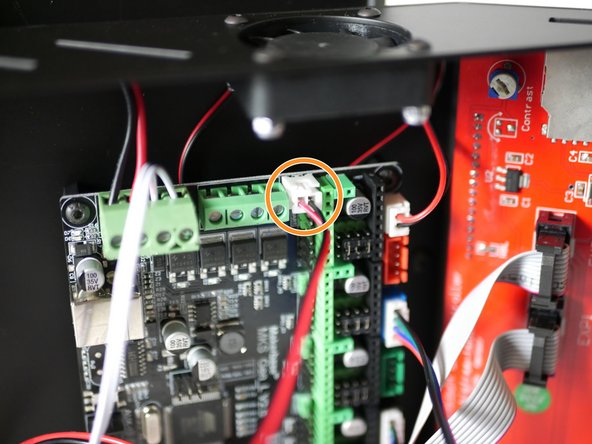

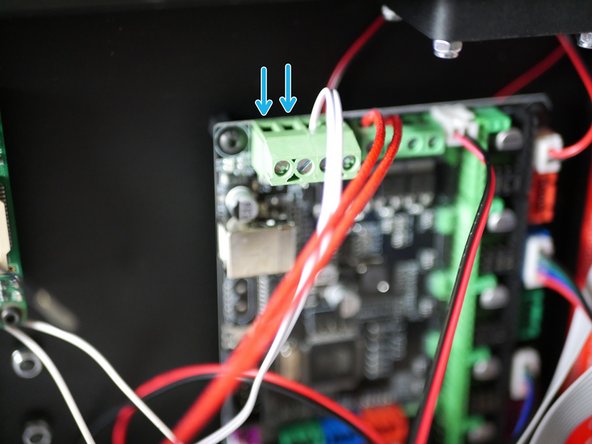

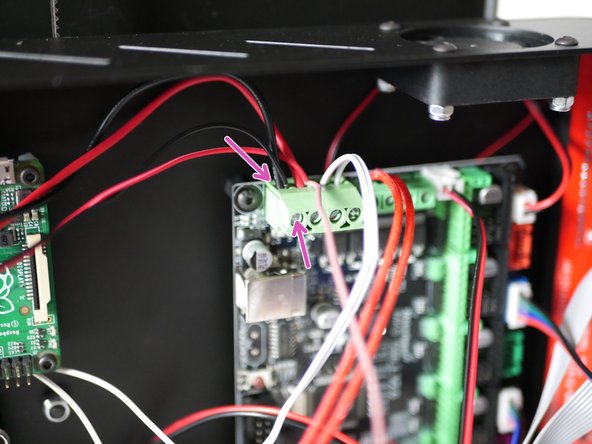

Plug the hotend thermistor into the control board.

-

Secure the hotend heater cables to the terminals on the control board.

-

Their polarity does not matter.

-

-

-

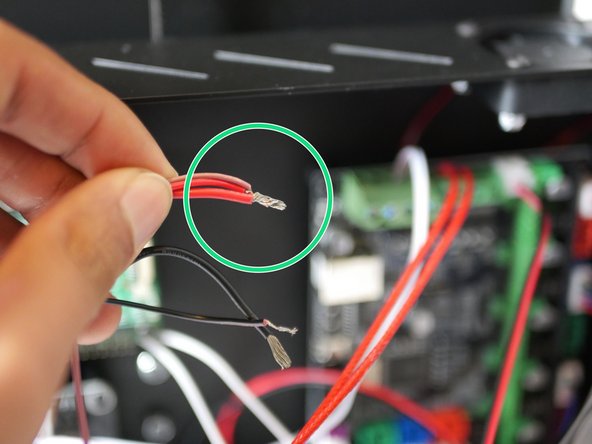

First prepare the 30mm hotend fan (the smaller fan that connects directly onto the hotend) by cutting of the connector and exposing some of the wire.

-

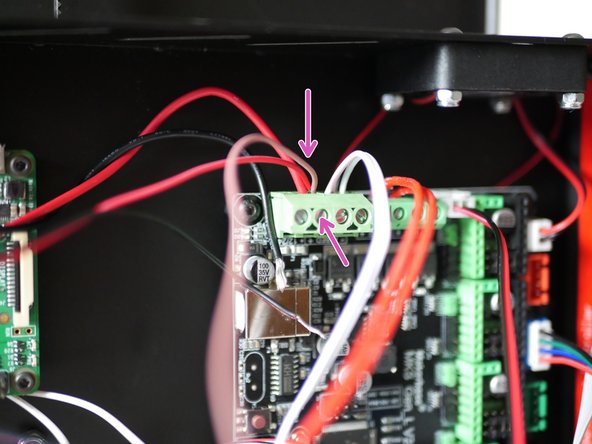

Unplug the power cables from the control board.

-

Take the red power cable, the red 30mm hotend fan cable and the brown cable from the probe and wind together.

-

Plug all three back into the control board and secure the terminal tightly.

-

-

-

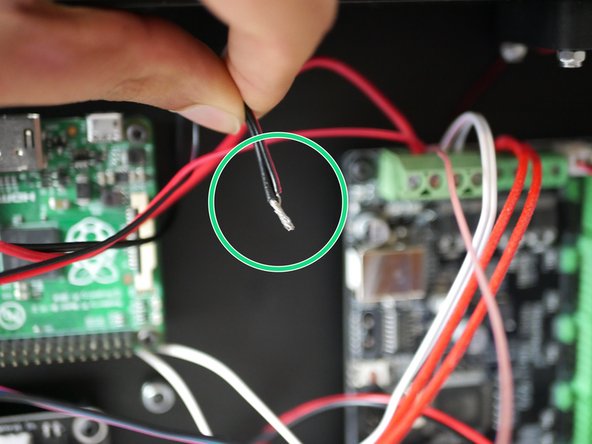

Take the remaining black power cable and black cable form the hotend fan and wind together.

-

Plug both back into the control board and secure the terminal tightly.

-

-

-

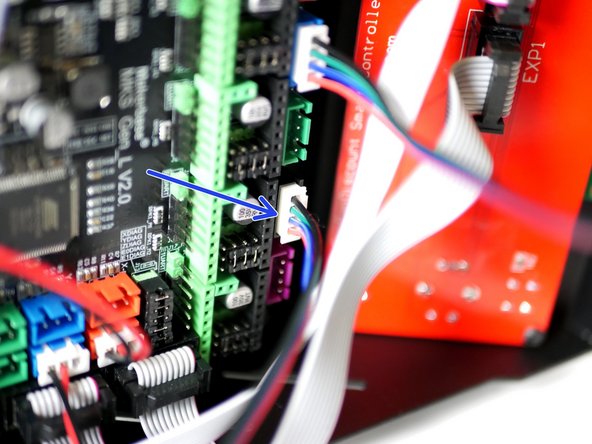

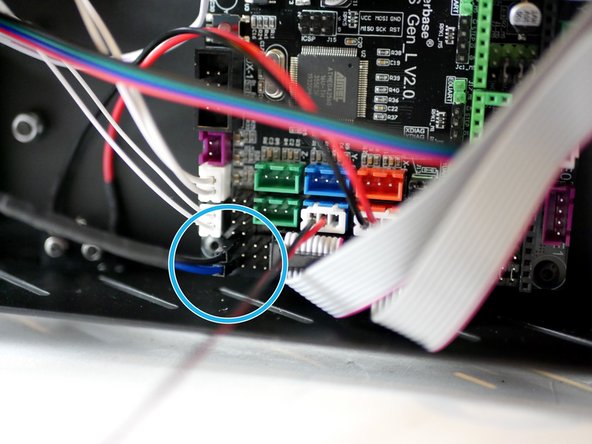

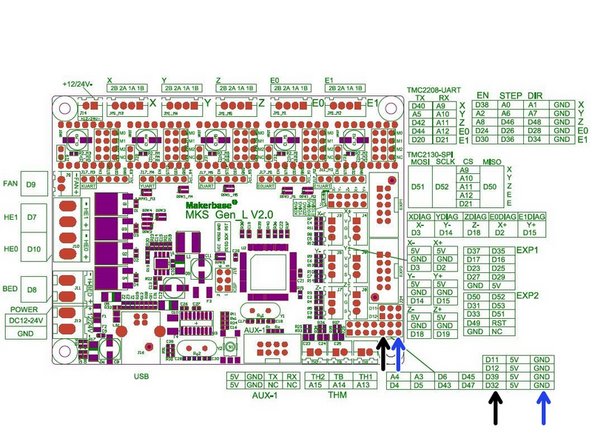

Plug the black and blue probe cables into the positions shown on the control board.

-

Black to D32

-

Blue to GND

-

NOTE: There is an empty pin between the black and blue cables!

-

-

-

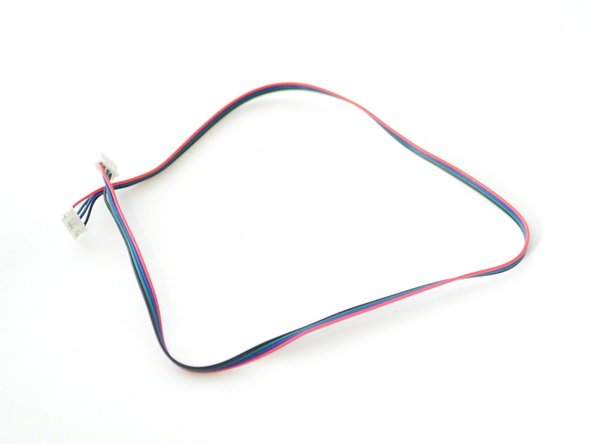

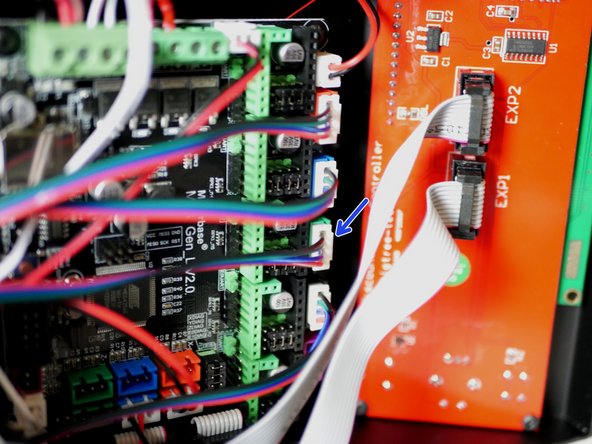

Take one of the 50CM motor cables.

-

Plug one end into the X-motor.

-

Plug the other end into the control board.

-

-

-

Take the remianing 50CM motor cable.

-

Plug one end into the Z-motor.

-

Plug the other end into the control board.

-

-

-

Skip this step if you do not have the TMC2208 driver upgrade.

-

The stepper drivers are the most delicate part of the Axis 3d printer and it is why we've also included a spare. Before opening, make sure that you are grounded (touch a large metal object) to avoid any chance of static damage.

-

The TMC2208 upgrade comes with either 3 or 6 drivers. If you have three you can use two on the x/y axes and keep one as spare, if you have 6 you can use them on the X/Y/Z/E0 (and E1 for dual extrusion) and have one spare.

-

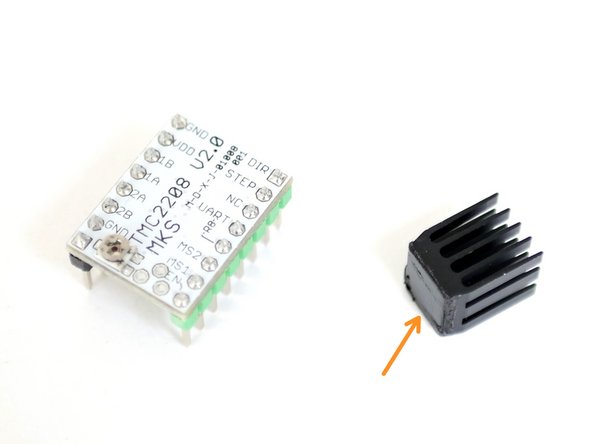

Prepare the TMC2208 stepper drivers by removing them from their packaging and sticking the heat-sink to the top.

-

Make sure that the heat-sink is not touching any of the pins. Orient the fins of the heat-sink as shown.

-

-

-

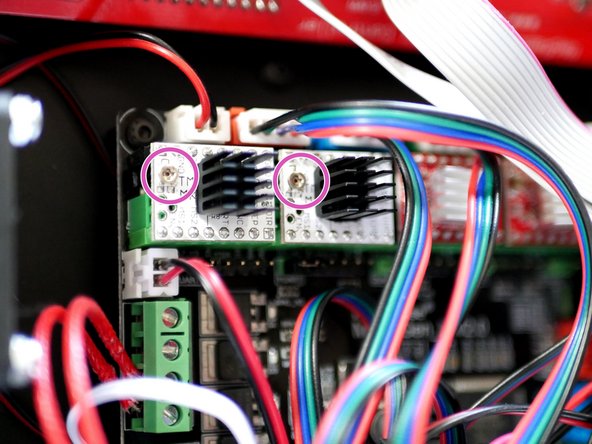

Skip this step if you do not have the TMC2208 driver upgrade.

-

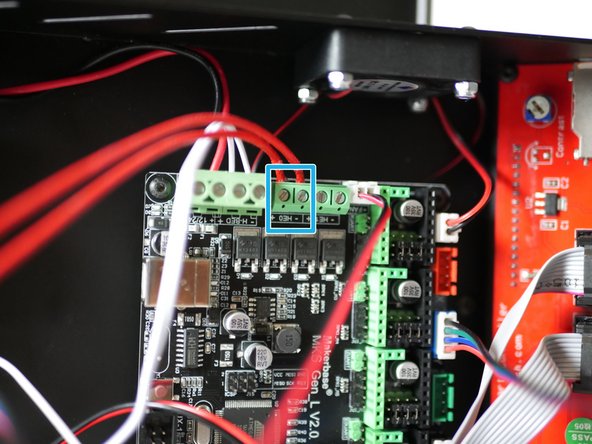

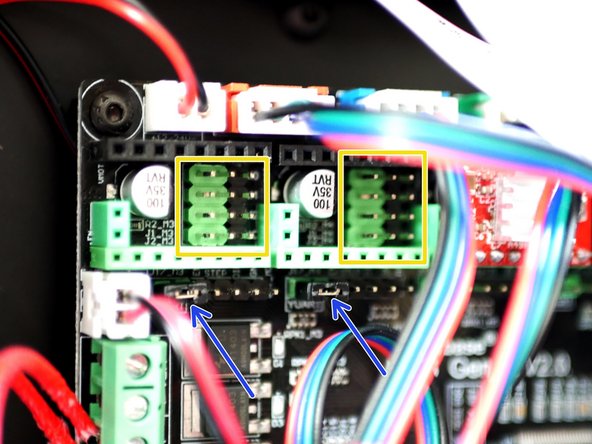

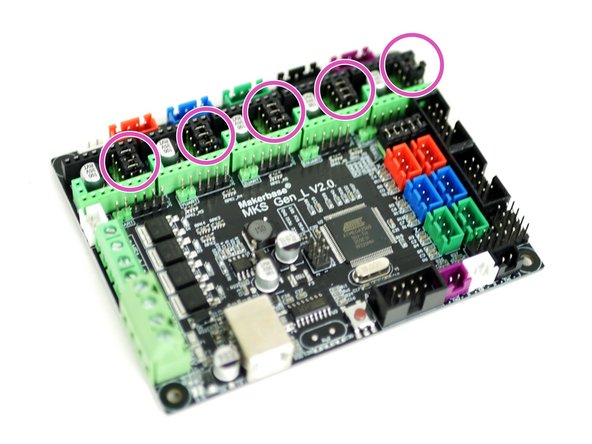

To install the TMC2208 drivers you will need to make sure that there are no jumpers plugged in at the stepper driver locations on the control board.

-

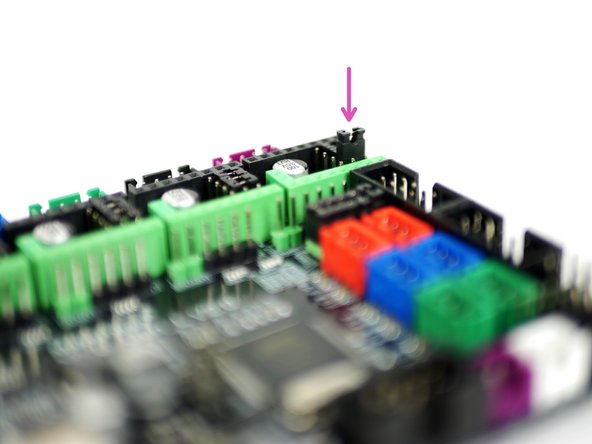

You will however need to make sure that there is one jumper placed on the UART pins for each axis you have a TMC2208 installed.

-

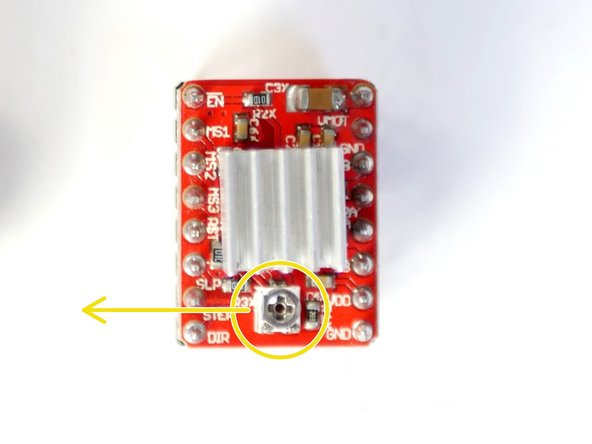

Plug the TMC2208 driver into the positions shown, make sure that the trim-pot is pointing towards the power terminals, installing the driver the wrong way round will destroy it.

-

Note, the trim-pot doesn't need adjusting as these drivers allow us to control the current via the firmware.

-

-

-

The stepper drivers are the most delicate part of the Axis 3d printer and it is why we've also included a spare. Before opening, make sure that you are grounded (touch a large metal object) to avoid any chance of static damage.

-

Prepare the A4988 stepper drivers by removing them from their packaging and sticking the heat-sink to the black chip.

-

Make sure that the heat-sink is not touching any of the pins. Orient the fins of the heat-sink as shown.

-

Trimpot: Adjust the trimpot so that flat side is pointing left as shown in the second photo.

-

-

-

If you do not have any of the TMC2208 drivers you will need to install the A4988 drivers like shown.

-

Under the A4988 driver positions on the control board there needs to be three jumpers installed like shown in the second and third photo.

-

Make sure that all of the drivers are orientated with their trim-pots pointing away from power terminals.

-

Plugging them in the wrong way round will destroy them.

-

Cancel: I did not complete this guide.

18 other people completed this guide.