-

-

Download the latest version of Cura here.

-

Run through the setup wizard and install it onto your computer.

-

Also download the benchy test print, this will be your first print and at the same time will test that the printer can safely print all of its geometries.

-

-

-

Open up the Cura application.

-

Run through the startup wizard.

-

Click on "add a non-networked printer"

-

Select the AXIS 3d printer.

-

Then hit next.

-

-

-

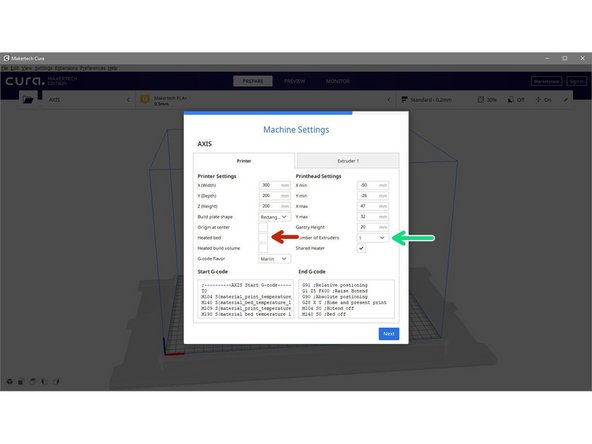

Here these setting will vary depending on your setup.

-

If you have a heated bed installed, check this box.

-

If you have dual extruders set-up, set number of extruders to 2.

-

Finally hit next and then finish.

-

-

-

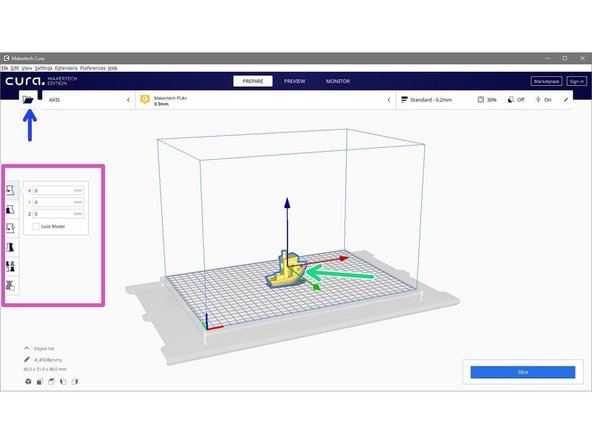

Click on the open file icon.

-

Navigate to and open the Benchy.stl file.

-

You can also use the tools on the side of the screen to move, scale and rotate your model.

-

-

-

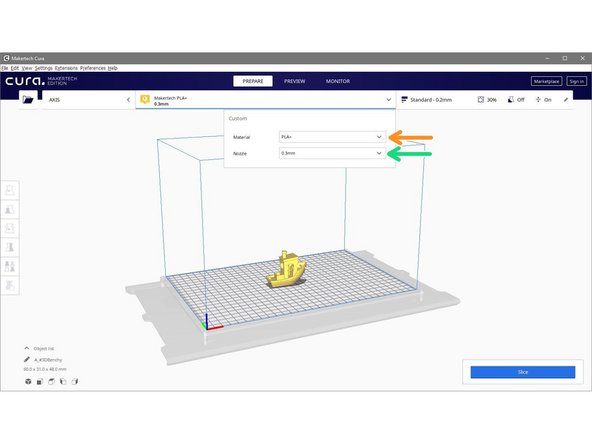

Select the nozzle size you have installed.

-

We recommend to have installed 0.4mm or 0.3mm.

-

Select the material.

-

we recommend picking from the Makertech list and choosing PLA+ for your first print.

-

-

-

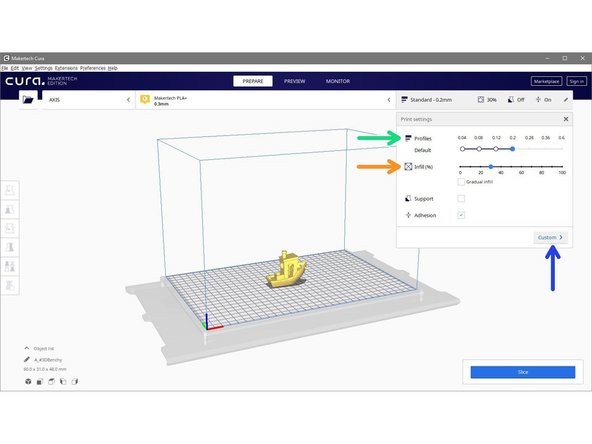

Leave setting as their defaults for the first print.

-

Profiles: Print profiles are default settings at different layer heights. The lower the number the more layers, hence more detail, but at the cost of greater print time.

-

Note, different nozzle sizes will have different layer height ranges.

-

Infill: This is the amount of material the printer will deposit inside the print. Between 20-30% is ideal in most cases.

-

Other options can also be tweaked by clicking custom. Hovering over an option will give you a description of its purpose.

-

You may find you need to adjust certain settings to get your printer working perfectly, we recommend posting in the forum for the best advise on this.

-

-

-

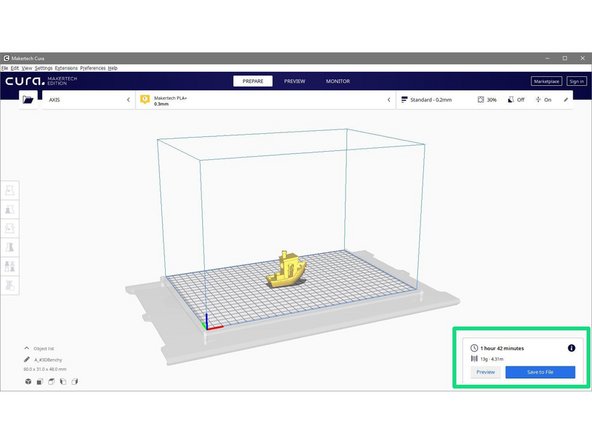

When happy with the settings, hit slice.

-

Slicing will convert your 3d model (an .stl file) into and .gcode file which in turn can be read by the printer to print your model.

-

If you have the LCD screen installed (from the highly recommended power pack upgrade) you can save your sliced file to an SD card and print directly from your printer.

-

-

-

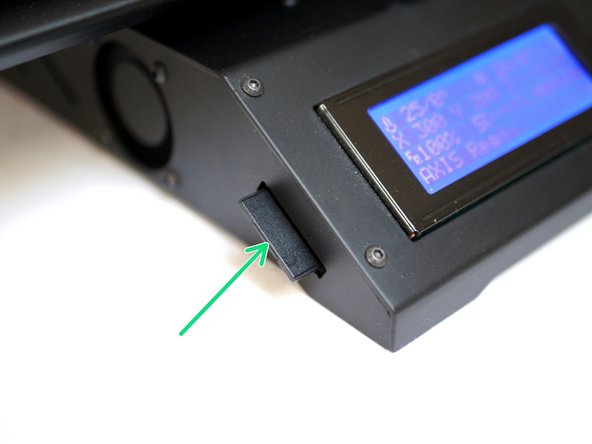

The most efficient way to print is via SD card, its self contained and doesn't rely on a computer connection.

-

After saving your .gcode to the SD card, slot it into the side of the Axis like shown.

-

Click the turn wheel once and turn it clock wise to scroll to the bottom of the menu.

-

Click on "Print from Media"

-

Print the .gcode file.

-

-

-

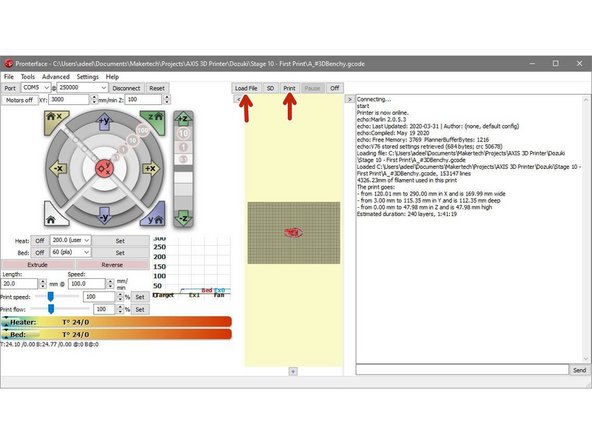

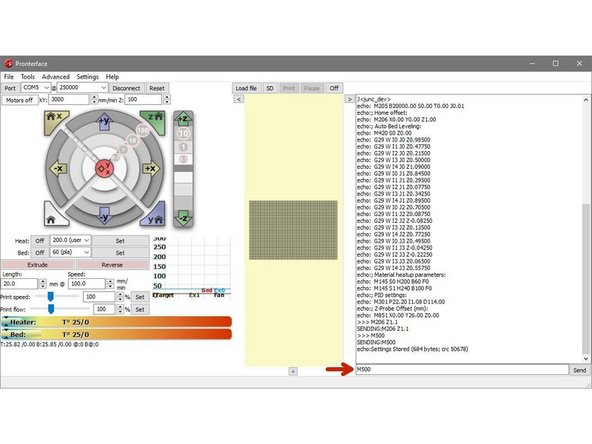

To print via USB you will first need to connect the Axis to your printer via USB.

-

Open your saved .gcode in pronterface and hit print once it's loaded.

-

In case of an error pronterface should receive a message in it's terminal to help diagnose.

-

-

-

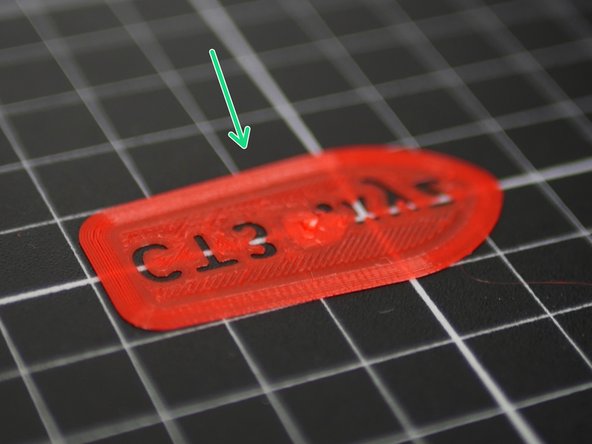

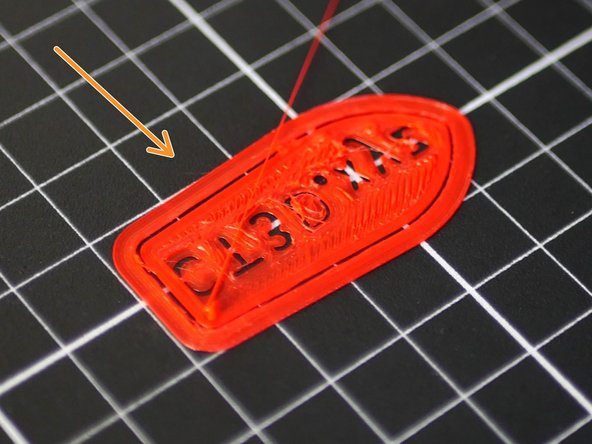

The most critical part of any print is its first layer, this is the contact point between the rest of the print and the print platform.

-

If printed too high then the model will detach mid-print, too low and will be a pain to remove form the platform.

-

What we want is a happy medium like this.

-

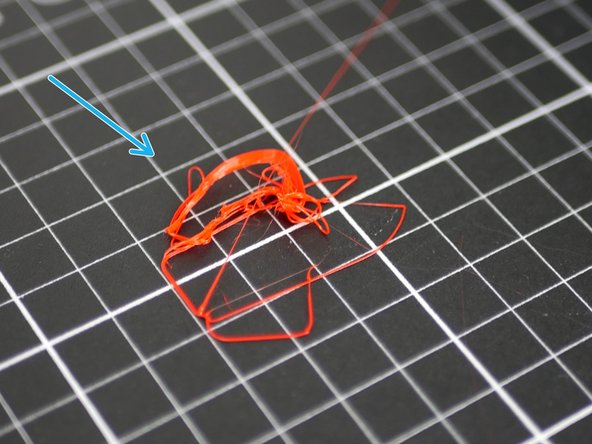

Too high - the first layer isn't sticking or the model has peeled off.

-

Too low - the nozzles is pressing the plastic down too much, or at worst digging into the bed.

-

If you find your first layer to be too low or high, stop the print and adjust the z-offset, as shown in next step.

-

-

-

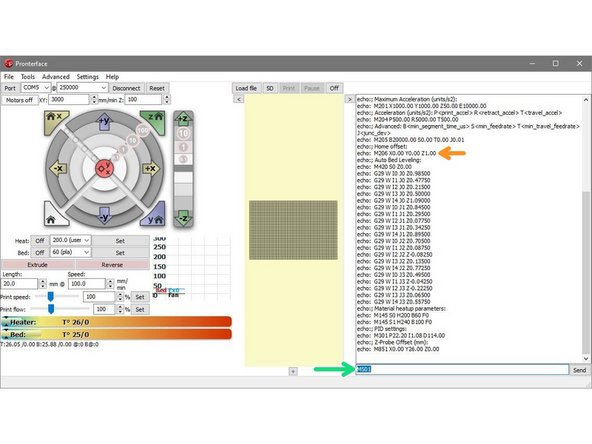

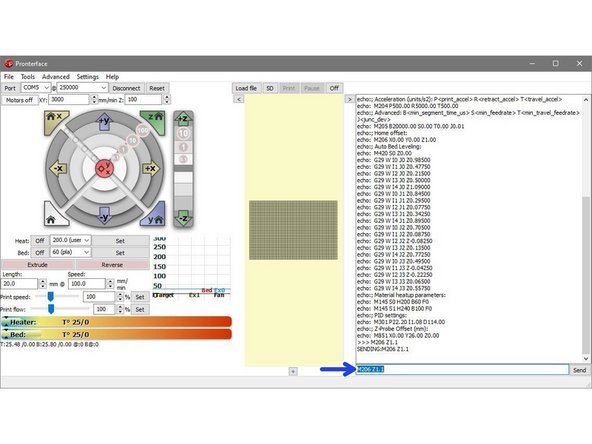

Connect the Axis to Pronterface.

-

Send M501 to check what your previous z-offset is set to.

-

In our case this was 1.0.

-

First layer too high, increase the Z-offset by 0.1mm.

-

First layer too low, decrease Z-offset by 0.1mm.

-

E.g. The first layer isn't sticking (it is too high) we will increase the Z-offset by 0.1mm to 1.1mm.

-

Enter M206 Z1.1 to set the new Z-offset.

-

Enter M500 to save to printer memory.

-

-

-

With the Z-axis offset dialled in you should have a successful first print!

-

If you're having issues with getting your first print done, post your issue in the forum here and we'll do our best to help!

-

Cancel: I did not complete this guide.

3 other people completed this guide.