-

-

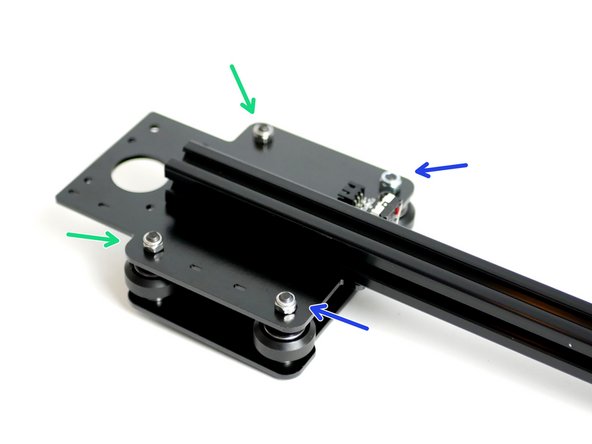

Prepare the Z-Axis Bracket

-

Two M5 x 8mm bolts

-

Two M5 T-Nuts

-

Orient as shown in the photos.

-

-

-

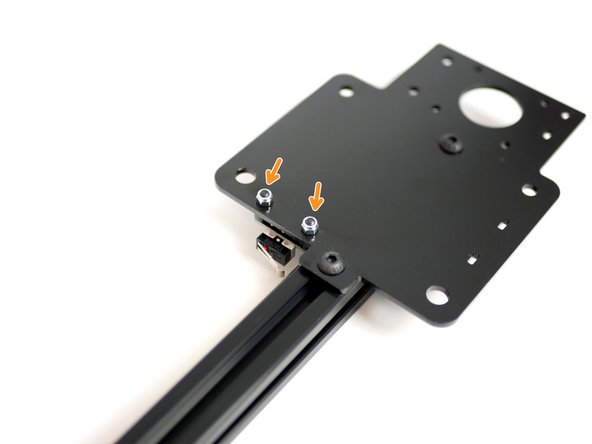

Fix the 2020 x 450mm Beam onto the Z-Axis Bracket.

-

Make sure the distance between the edge of the z-axis bracket and beam is 40mm for the Proforge 2 and 50mm for the Proforge 2S

-

Keep as straight and square as possible to the bracket. Use the part of the bracket that comes out to help gauge this.

-

-

-

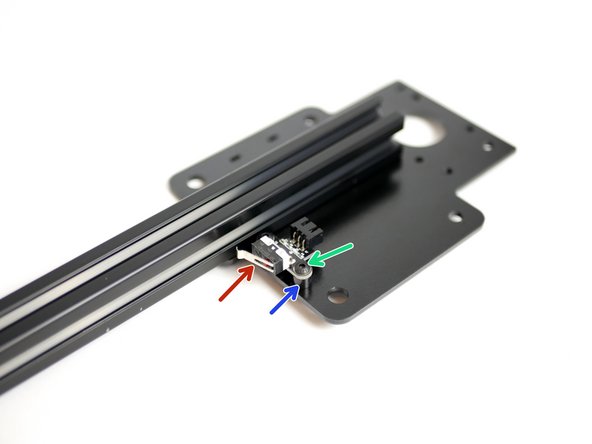

Install the Endstop onto the Z-Axis Bracket.

-

Two M3 x 14mm bolts

-

Two M3 x 5mm Spacers

-

Two M3 Nyloc Nuts

-

-

-

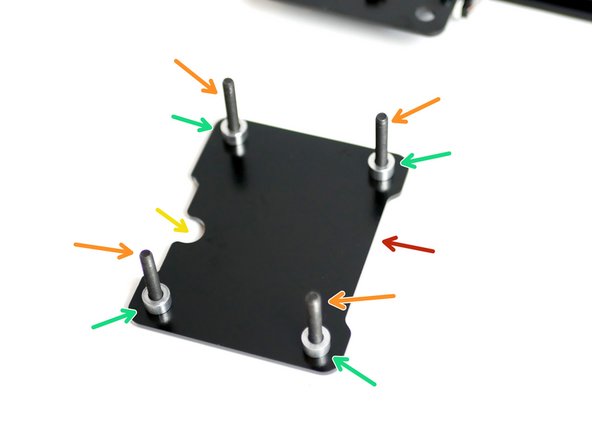

Prepare the Z-axis support bracket with rollers and spacers:

-

Z-Axis Support Bracket

-

The support bracket should be oriented so that the circular cut out should be on the lower left.

-

Four M5 x 35mm Bolts

-

Six M5 x 6mm aluminium spacers. Four beneath the Roller Wheels, two above the Roller Wheels on the same side as the cutout

-

-

Two Eccentric Spacers. opposite side of the cutout

-

Match the direction of the eccentric spacer in third image.

-

-

-

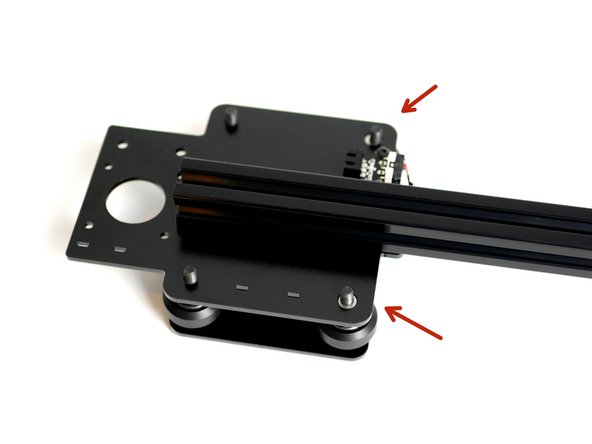

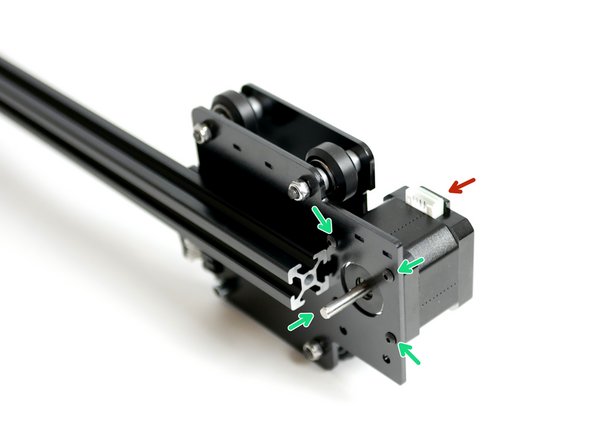

Place carefully over the spacer/roller stack the main Z-Axis Bracket Assembly.

-

Match the photographs, the eccentric spacers should be on the side of the endstop.

-

Tighten firmly the Nuts that are holding together the rear side of the assembly.

-

Tighten loosely the nuts holding together the front of the assembly with the eccentric spacers.

-

The eccentric spacers should be able to turn freely - they will be tightened later.

-

-

-

Fix a NEMA 17 Motor onto the bracket as shown in the image.

-

Four M3 x 6mm bolts.

-

Orient the Motors cable connector upwards.

-

Cancel: I did not complete this guide.

29 other people completed this guide.