-

-

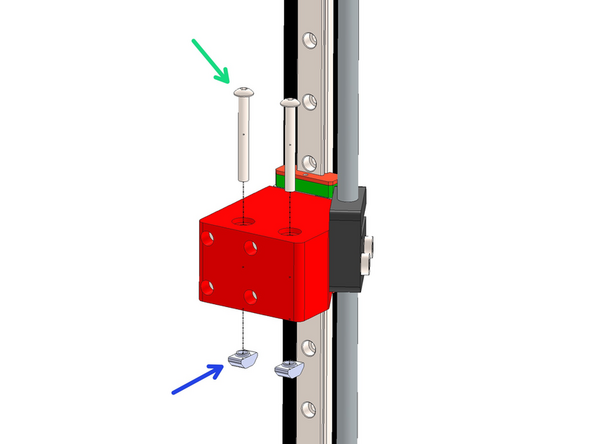

Prepare 12 rail mounts as shown by loosely fastening a T-nut onto the M5 bolt.

-

M5 x 8mm Button Head

-

M5 T-nut

-

-

-

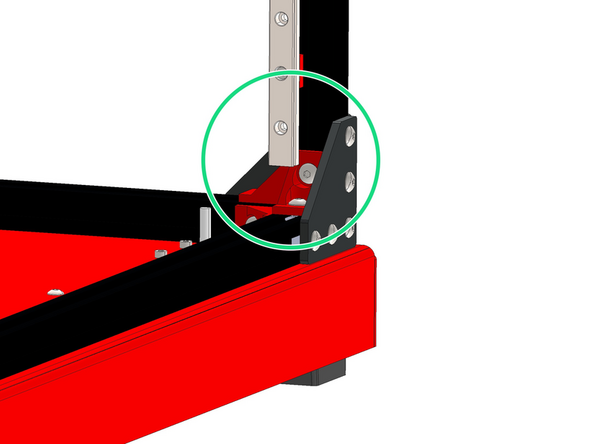

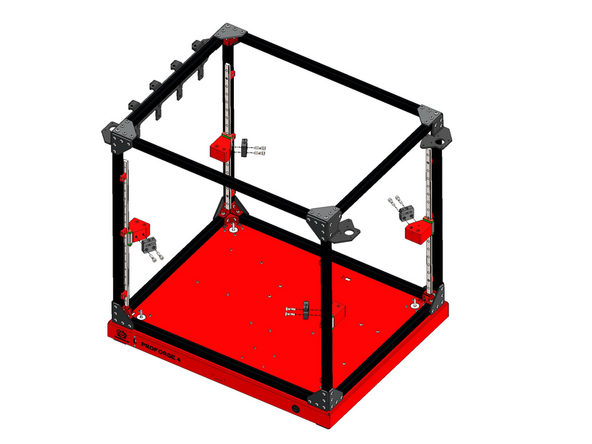

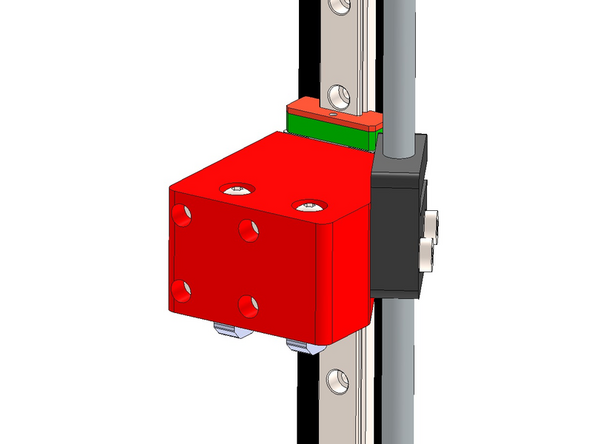

Fix the mount assemblies from the previous steps onto the four 460mm long MGN12 rails.

-

Space them out as shown with two fixed one forth edge and the third in roughly the middle.

-

M3 x 6mm Cap Bolt

-

Use the orange stoppers to prevent the carriage from falling off the rail.

-

-

-

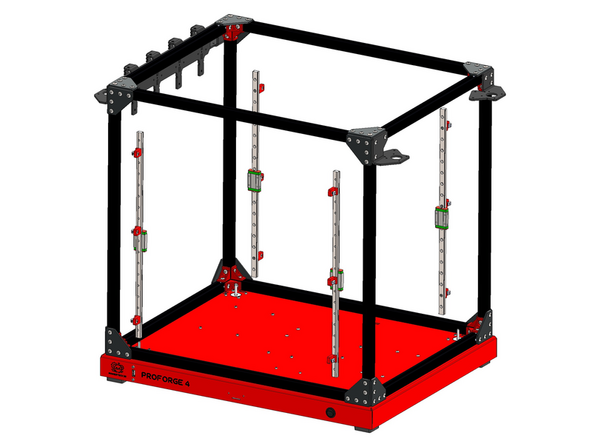

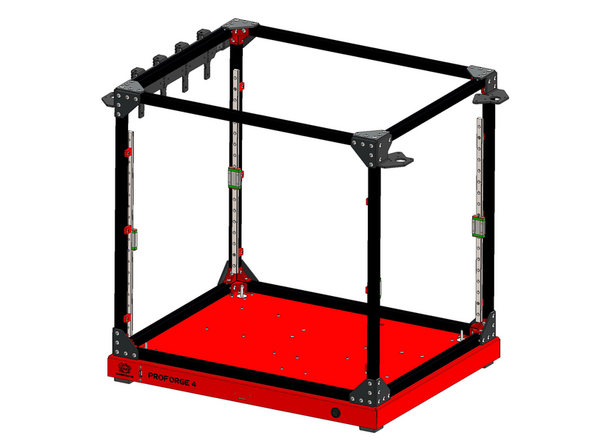

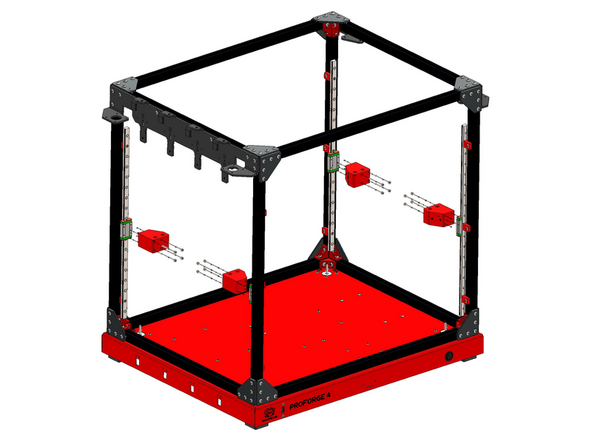

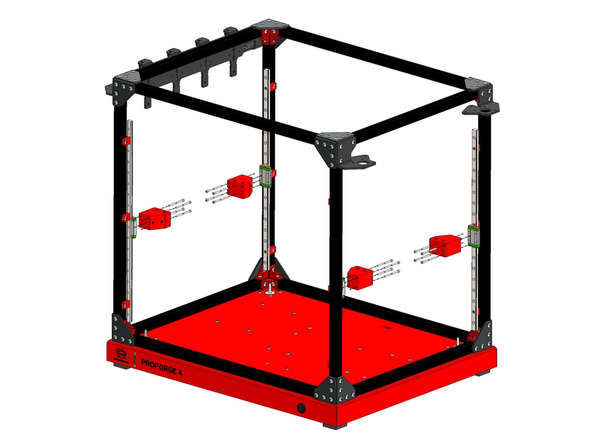

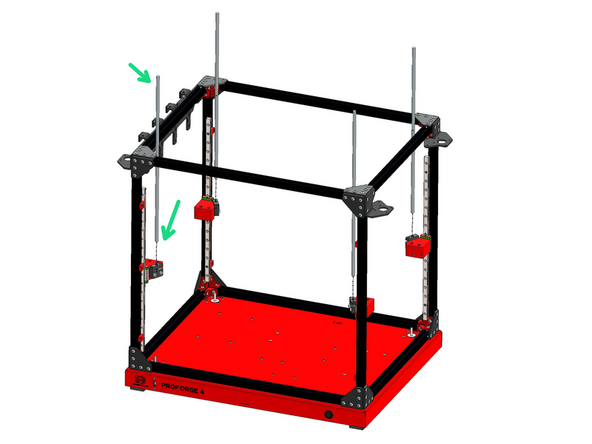

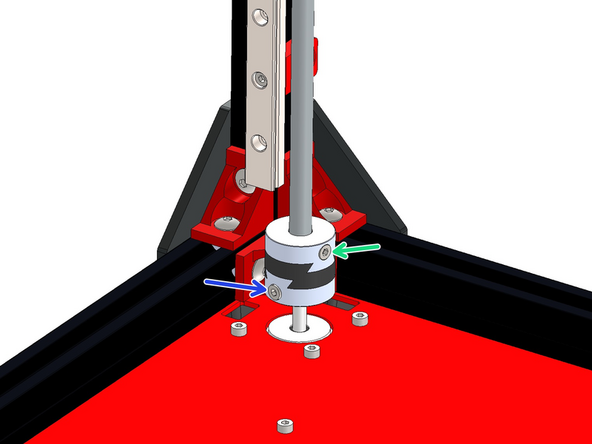

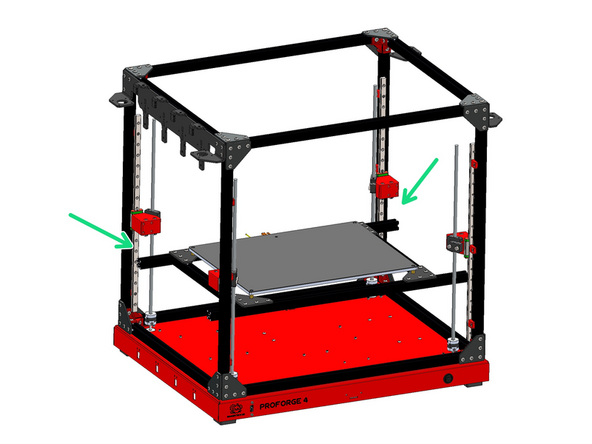

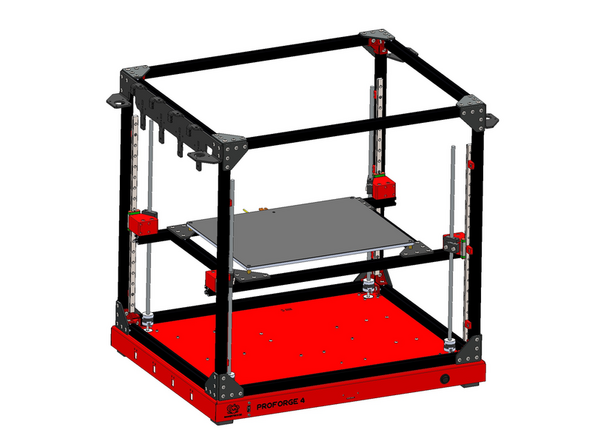

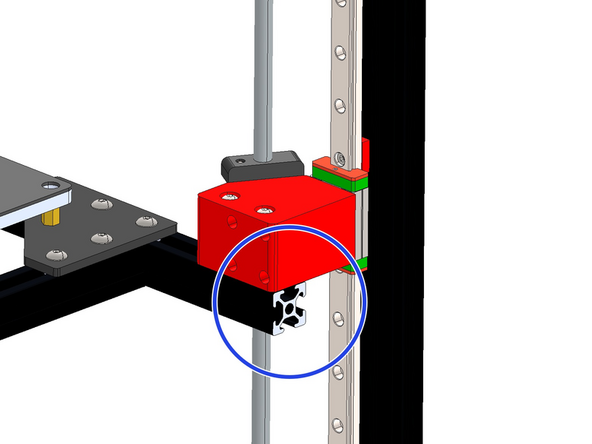

Mount the rail assemblies onto the inside of the frame as shown.

-

Mount the rail assemblies onto the inside of the frame as shown.

-

-

-

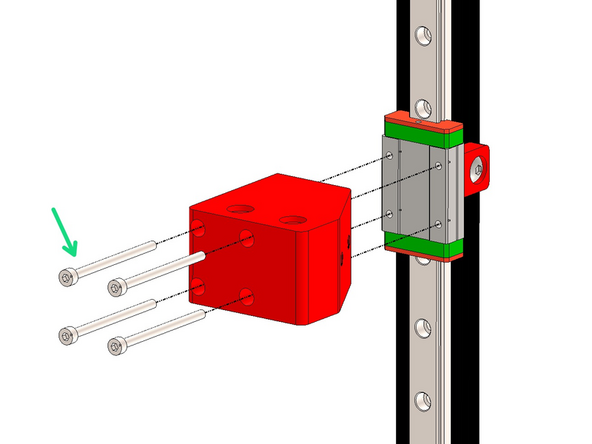

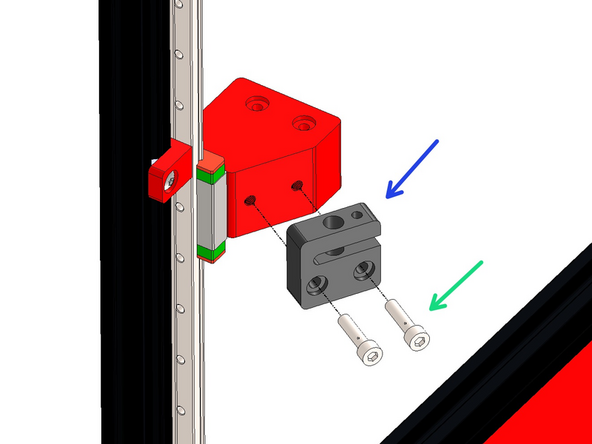

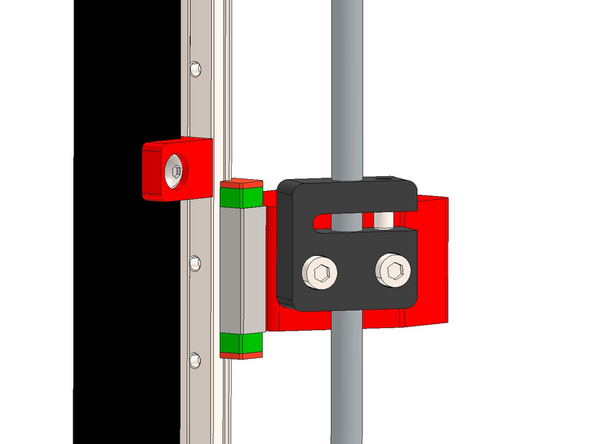

Mount Z-brackets onto the rail carriages with M3 x 45mm Cap Bolts.

-

Match the orientation of the brackets as shown in the images.

-

-

-

Fix the lead screw nut onto the bracket.

-

M5 x 20mm Bolt (Button head - image is incorrect)

-

Orientate the nut as shown.

-

-

-

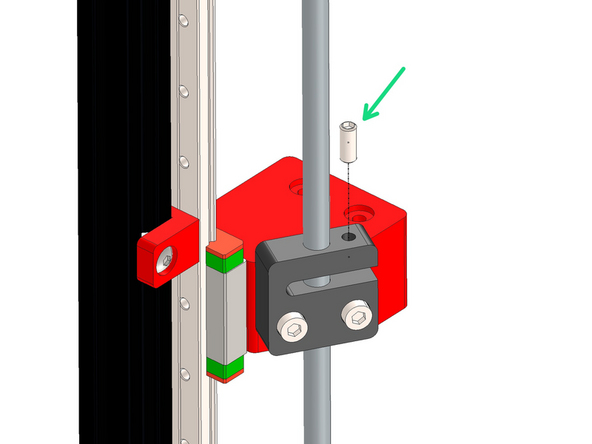

Add the M5 x 12mm Grub screw to the lead screw nut as shown.

-

Tighten until you feel some resistance, the purpose of this grub screw is to prevent backlash along the nut and lead screw.

-

Do not tighten to the point that the lead screw will no longer turn. You should still have smooth rotation of the lead screw through the nut.

-

-

-

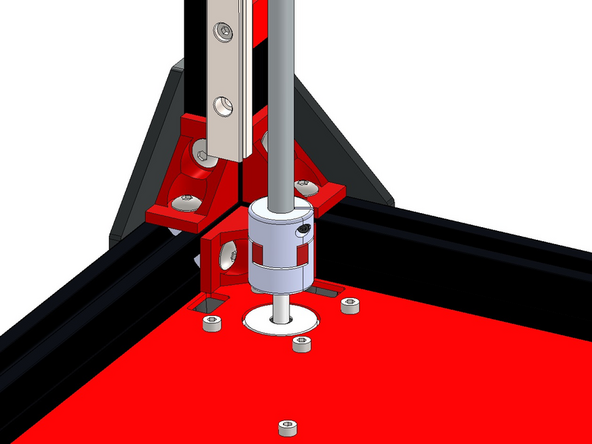

Fix the lead screws to the Z-motors with the plum couplings.

-

Tighten the bolts on the coupling to fix in place.

-

If you have the upgraded Oldham Couplings please see the next step.

-

-

-

Fix the lead screws to the Z-motors using the Oldham Couplings. They come in a bag in three pieces, the pieces can be slid on to each other to create one coupling.

-

M3 x 6mm Bolt

-

M3 x 8mm Bolt

-

There was an oversight with an initial batch (pre-2024) of the couplings where the correct number of fasteners were not included - they have now been shipped to everyone.

-

-

-

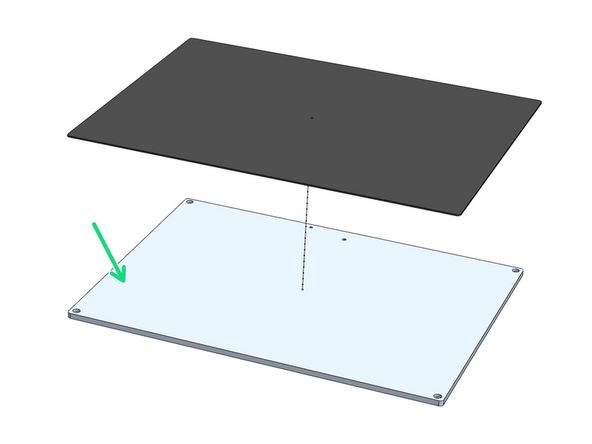

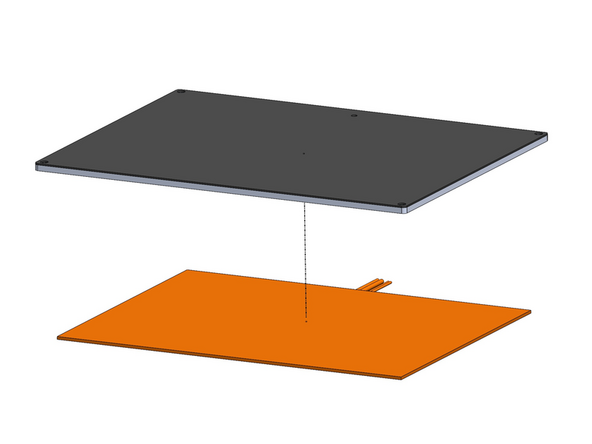

Stick over the aluminium platform plate the magnetic flex-plate sticker.

-

You may find this sticker, being magnetic, stuck onto the back of the black PEI flexplate in the packaging.

-

Ensure it is stuck onto the side shown in the images.

-

Peel away the backing paper from the magnetic sheet. Begin by sticking it to one of the shorter edges pressing it down carefully preventing any air bubbles. Use a credit card to press the sticker down, pushing out any potential air pockets.

-

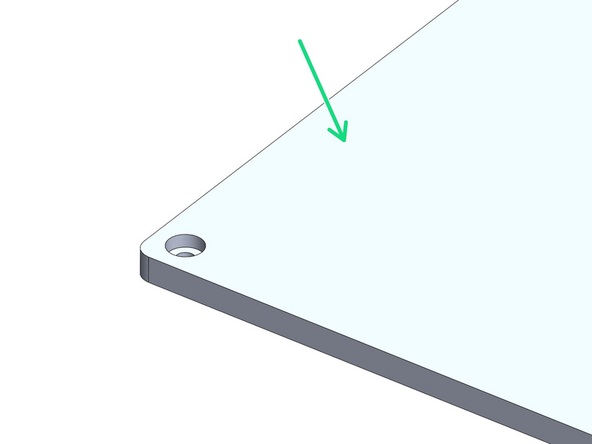

After sticking the sheet down use a craft/box knife to cut away where shown to expose the holes. Use a pin to poke through the other side of the plate to make where you should cut.

-

You don't need to be particularly neat about these cuts, this sticker will have the flexplate go over it.

-

-

-

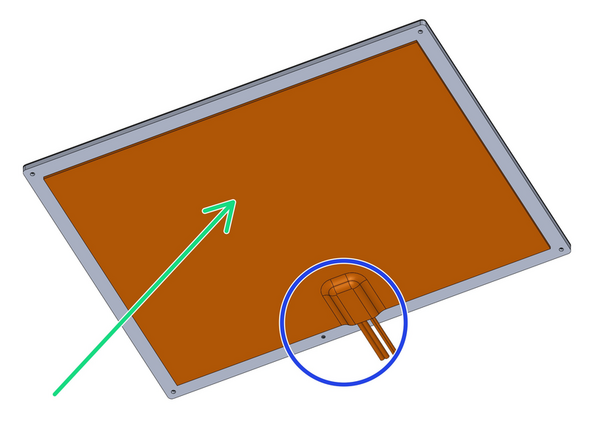

Peel the backing paper away from the heater pad.

-

Fix the heater onto the centre of the underside of the platform as shown.

-

Ensure the cables are on the side with the M4 threaded hole as shown.

-

Make sure the hole is not covered either.

-

-

-

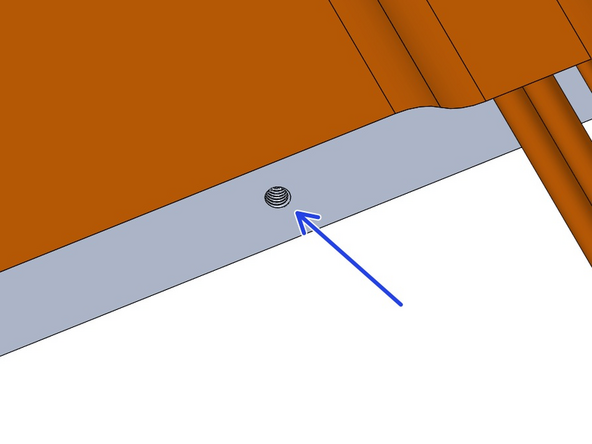

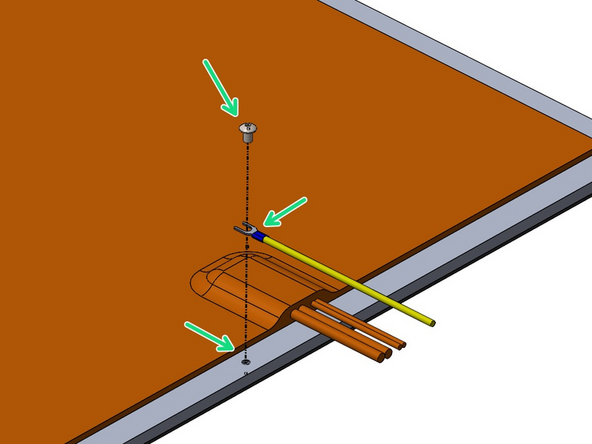

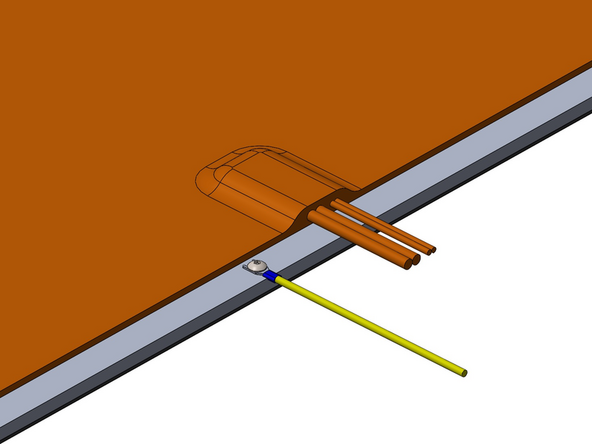

Fix the 1M Earth cable to the platform with an M4 x 6mm button head bolt.

-

-

-

Cut 70cm of the braided sleeving and wrap the heater and earth cables with it.

-

-

-

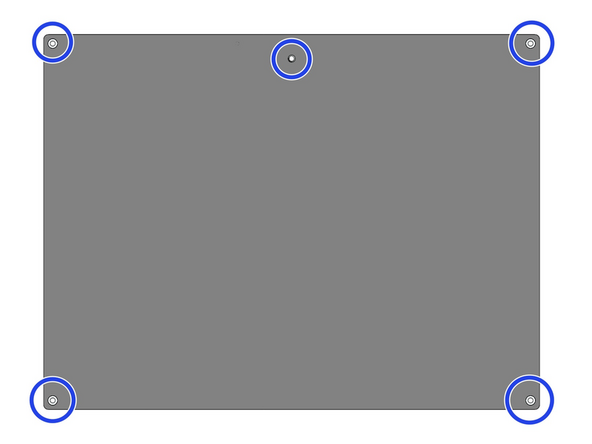

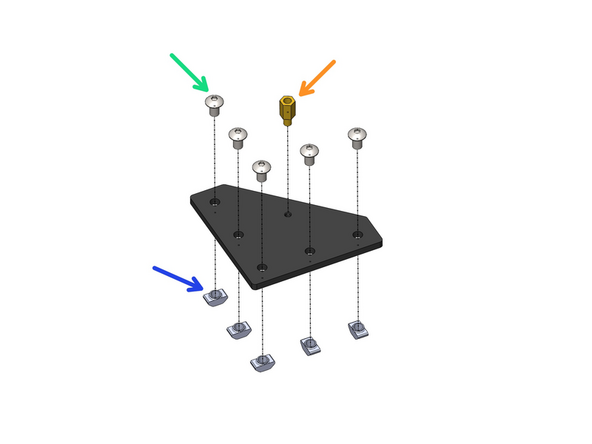

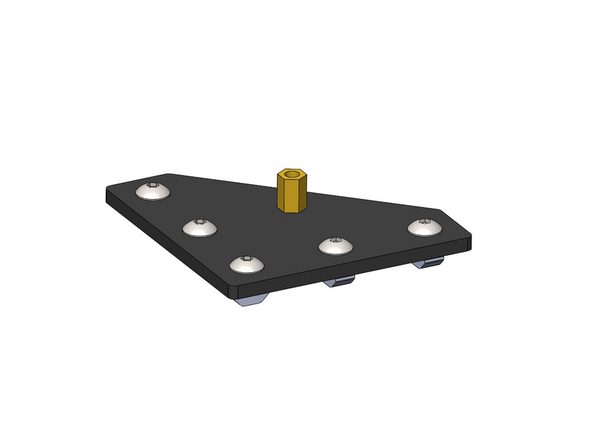

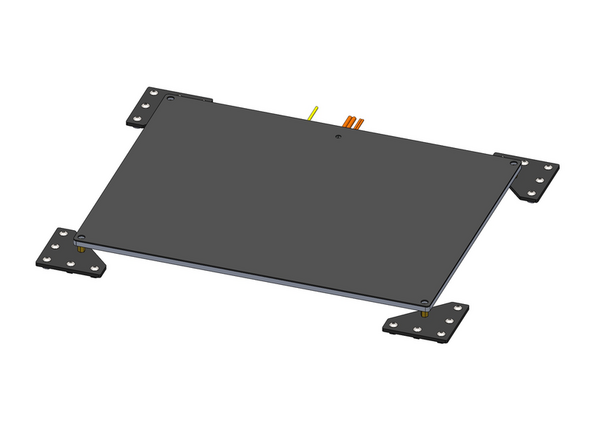

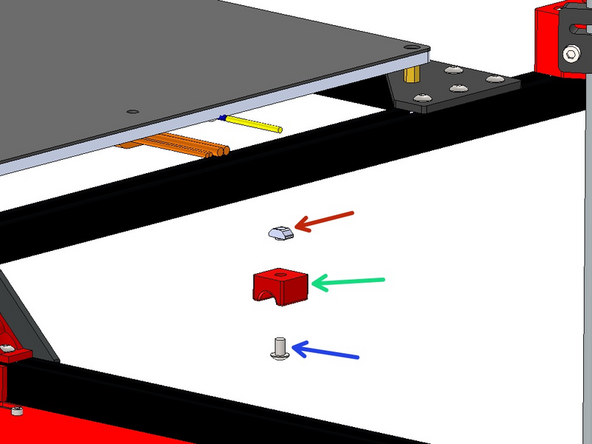

Prepare the four platform brackets as shown.

-

M5 x 8mm Button

-

M5 T-nut

-

M4 x 10mm Brass Standoff

-

-

-

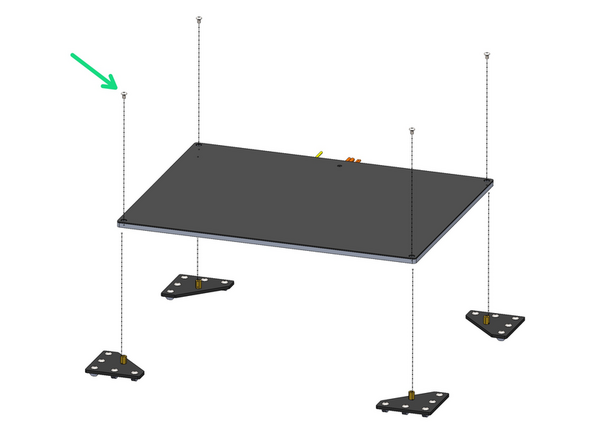

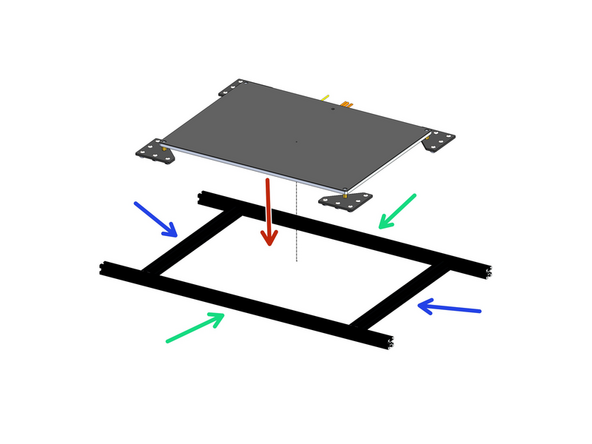

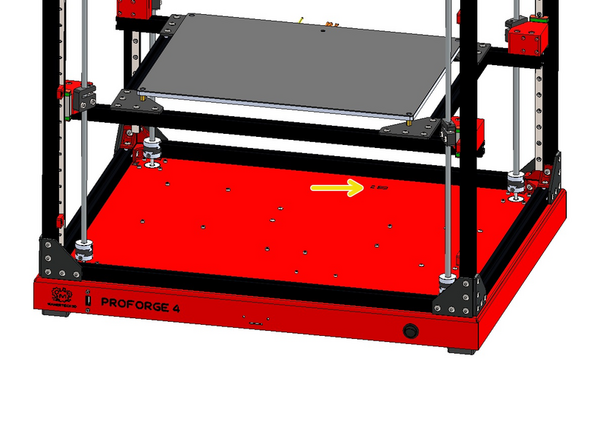

Arrange the extrusions as shown and mount the platform assembly onto them.

-

2020 Extrusion - 630mm

-

2020 Extrusion - 333mm

-

Make sure to push the cables through the centre of the frame.

-

-

-

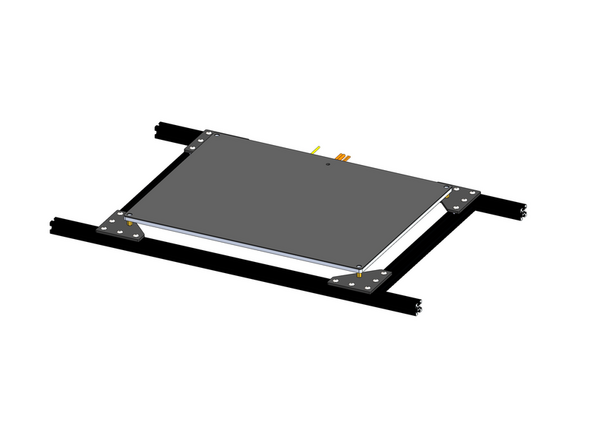

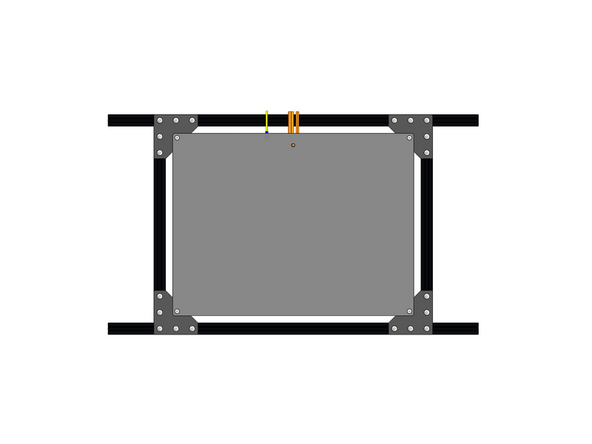

Mount the platform assembly onto the z-brackets.

-

Align the extrusions flush with the brackets.

-

-

-

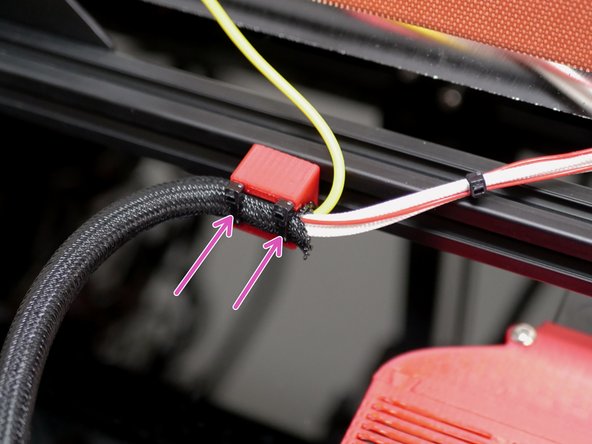

Fix the cables to the bottom of the platform frame with the 3d printed bracket.

-

M5 x 8mm Button

-

M5 T-Nut

-

Use cable ties to secure the heated bed cables to it as shown.

-

Route the cables into the base.

-

-

-

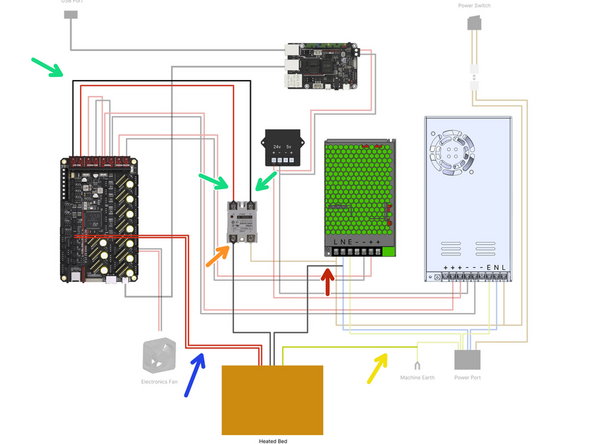

Wire the heated bed as shown:

-

Bed Signal Cables - 30cm

-

Bed Power Cables

-

One cable to SSR Relay

-

One cable to N terminal on 48v PSU

-

Bed Thermistor - Plug into control board

-

Bed Earth - Bolt to Base

-

Cancel: I did not complete this guide.

18 other people completed this guide.