-

-

If you are building the Dual Switching Extruder complete only steps 7 and 8 of this stage.

-

-

-

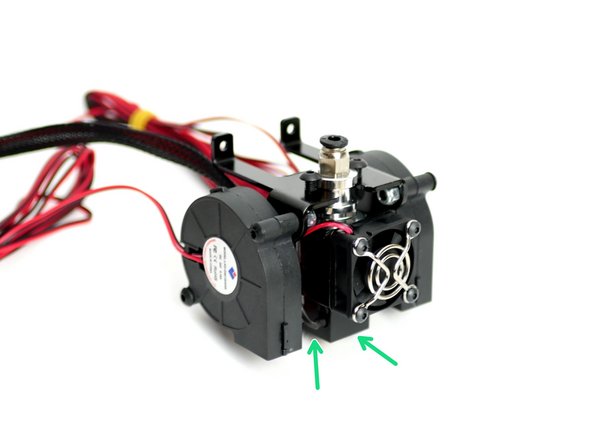

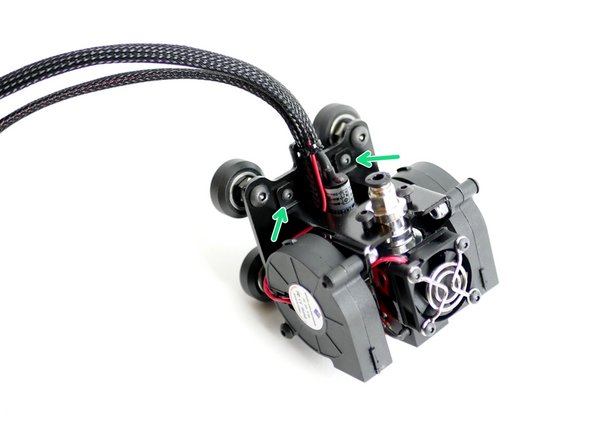

Fix both of the blower fans to the sides of the Hotend Mount.

-

M4 x 22mm

-

M4 Nyloc Nut

-

-

-

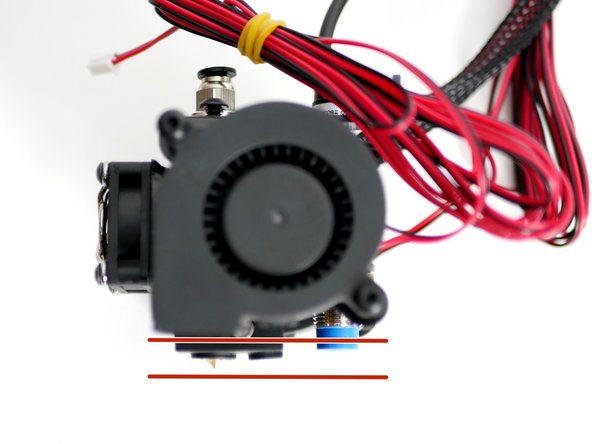

Thread two M4 x 8mm bolts onto the top of the HotEnd bracket.

-

Slide the HotEnd in and clamp it down with the two M4 bolts.

-

Keep the this side of the HotEnd parallel with the front of the Hotend Mount

-

Make sure that the cables from the Hotend are facing the left side.

-

-

-

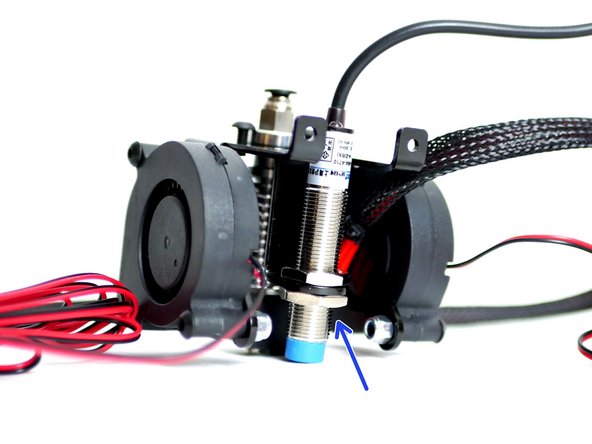

Clamp the probe onto the back of the Hotend Mount.

-

Keep the bottom of the probe a few millimeters above the tip of the nozzle.

-

-

-

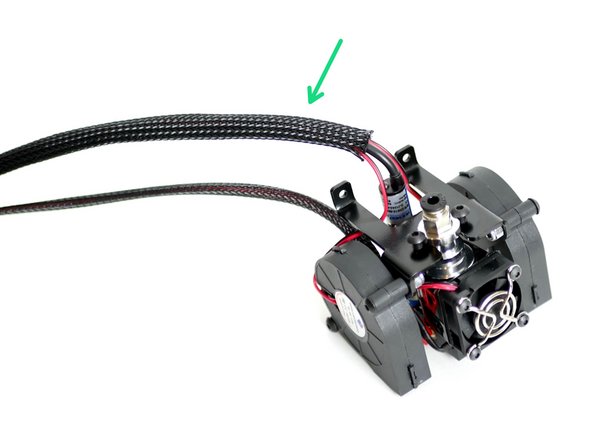

Cut 1 meter of the braided cable sleeving.

-

Melt the ends with a lighter to prevent fraying.

-

-

-

Cut 1 meter of cable sleeving.

-

Melt the ends with a lighter to stop them from fraying.

-

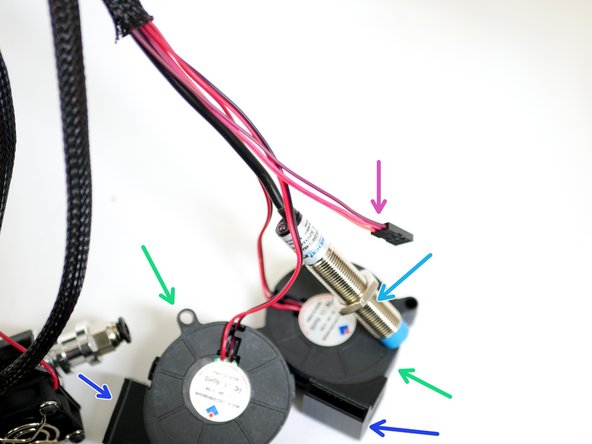

Slide the sleeving over the cables from:

-

Blower Fan (x2)

-

Probe

-

Servo Cable (From the Dual Extruder Upgrade box)

-

You can also snap on the fan shrouds here too.

-

Place this assembly to one side for now.

-

-

-

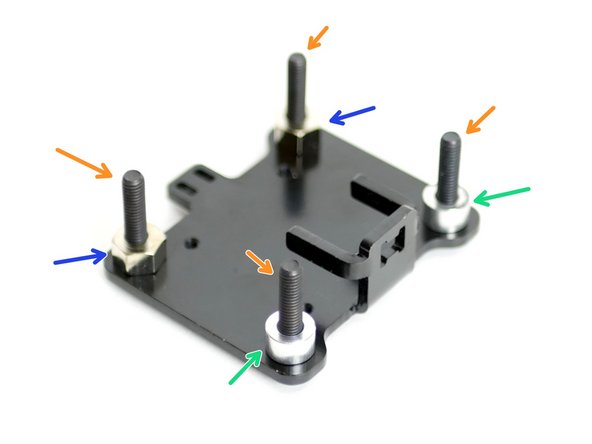

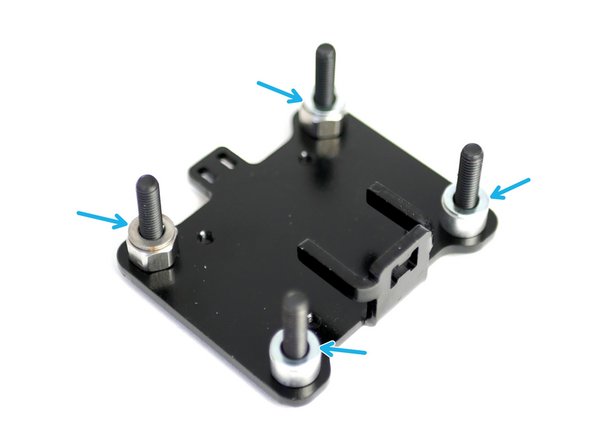

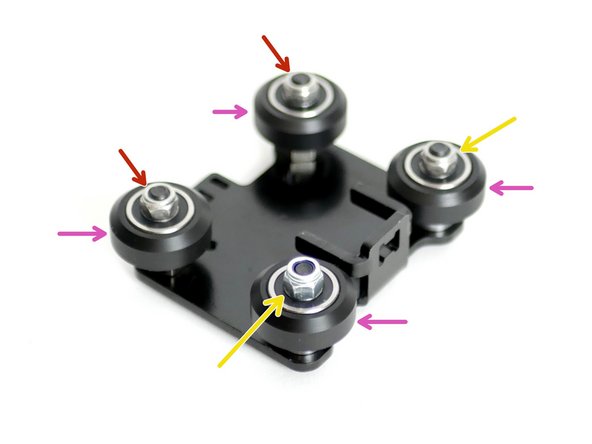

Assemble Y-Carriage rollers as shown in the images:

-

Four M5 x 25mm bolts

-

Two M5 Spacers

-

Two Eccentric Spacers

-

Four M5 Washers

-

Roller Assembly

-

Two M5 Nylocs - Tighten Firmly

-

Two M5 Nylocs - Tighten Loosely (eccentric spacer should still be able to turn)

-

-

-

Fix the HotEnd Mount assembly onto the Y-Carriage.

-

M3 x 8mm bolt

-

Cancel: I did not complete this guide.

21 other people completed this guide.