-

-

Slide the camera into the 3D printed camera case.

-

Secure it in place with:

-

M3 x 18mm Cap Head Bolt

-

M3 Nylon Nut

-

-

-

Secure the assembly to the inside left of the printer’s front frame using an M4x12mm button head bolt and an M4 T-nut.

-

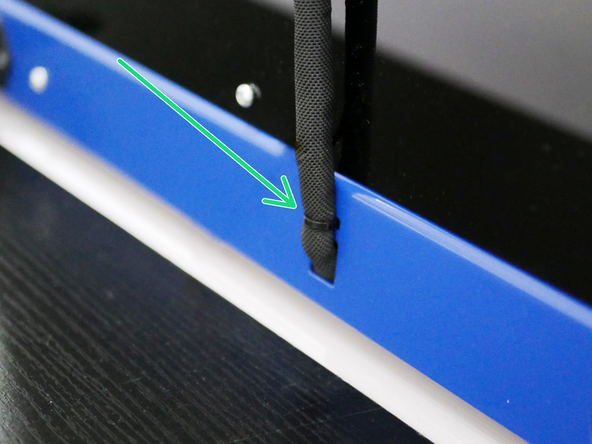

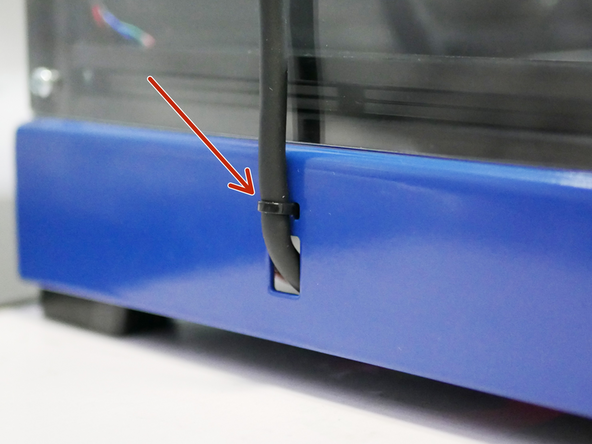

Route the USB cable up from under the base and connect it to the camera.

-

To avoid potential camera feed issues, we’ll take a few precautionary steps:

-

Ensure the connector is securely mounted and the cable is free of kinks, especially in exposed areas.

-

The cable is shielded, but interference is still possible — route it on the opposite side of the extrusion from the motor cable.

-

-

-

Plug in the gantry motor cables.

-

These are the twisted cables that came with the LDO motors.

-

Feed them into the base.

-

Feed into the base with the top right motor cable the endstop cable.

-

-

-

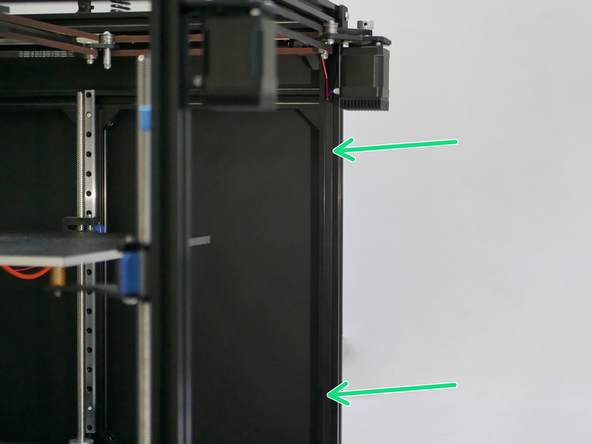

Use the included cable covers to hide the cables in the extrusions.

-

The camera cable should be excluded.

-

-

-

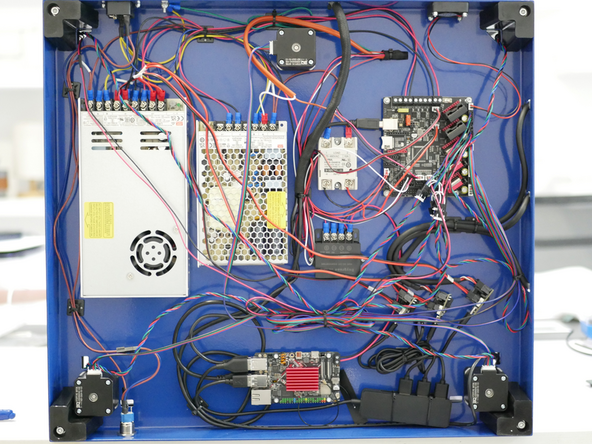

Lay the printer front side down to gain access the the electronics underneath.

-

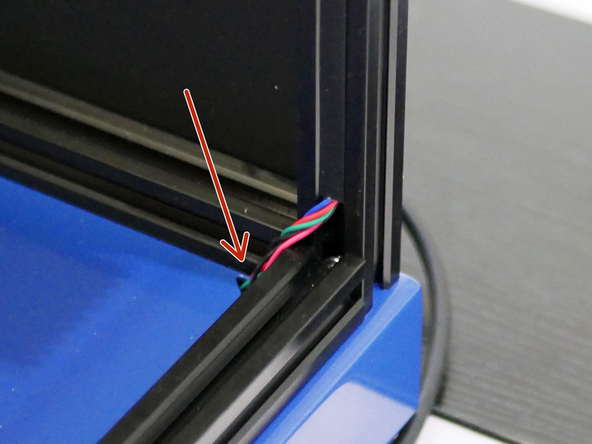

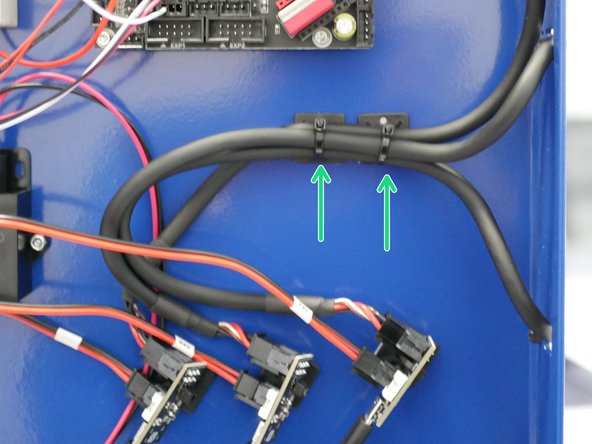

Feed the tool carriage cable loom into the base and use a cable tie to secure it in place.

-

Feed the cables from the print heads into the base and use a cable tie to secure them in place also.

-

-

-

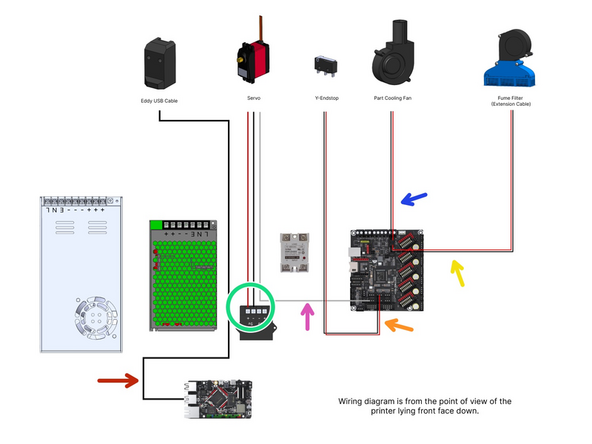

Eddy Probe to USB port on BTT Pi.

-

Servo:

-

Black and Red power cables to the 5V terminals on the converter.

-

White signal cable to mainboard.

-

Y-Endstop

-

Part cooling

-

Enclosure Fan (Extension Cable)

-

-

-

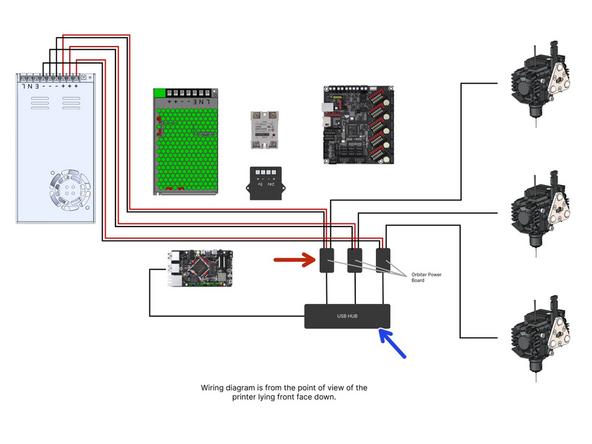

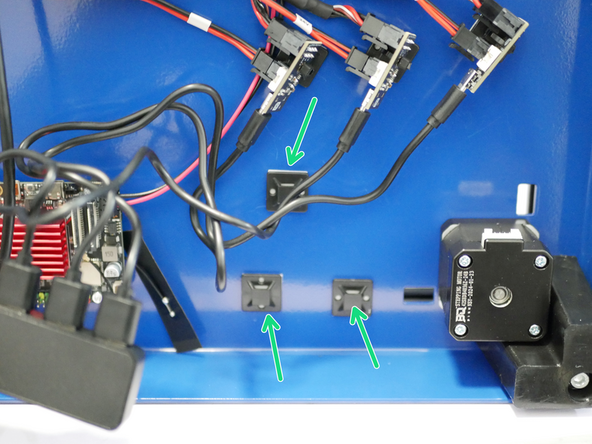

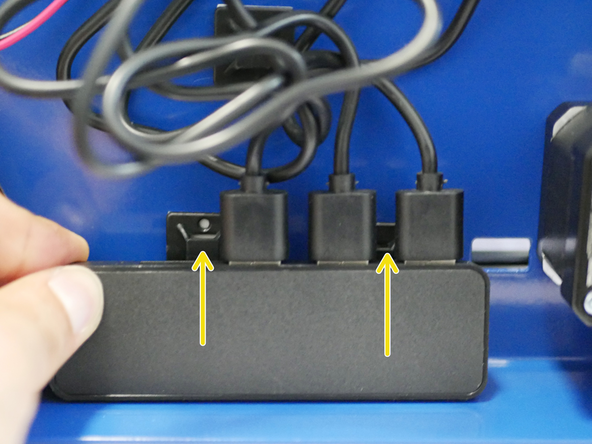

Use the cable tie mounts and cable ties to hold everything together.

-

When securing the cable tie mounts for the USB hub, ensure they are spaced so the cable ties run between the ports on the hub.

-

-

-

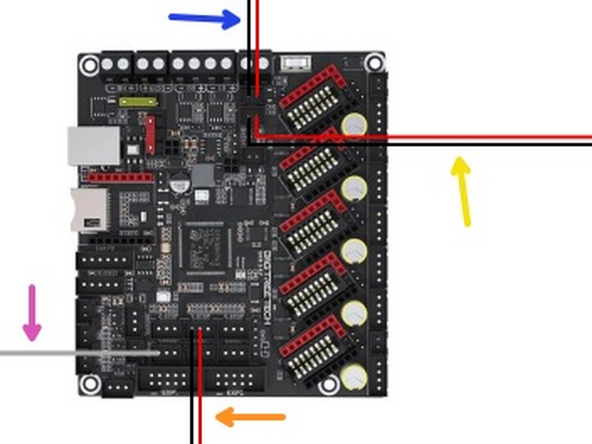

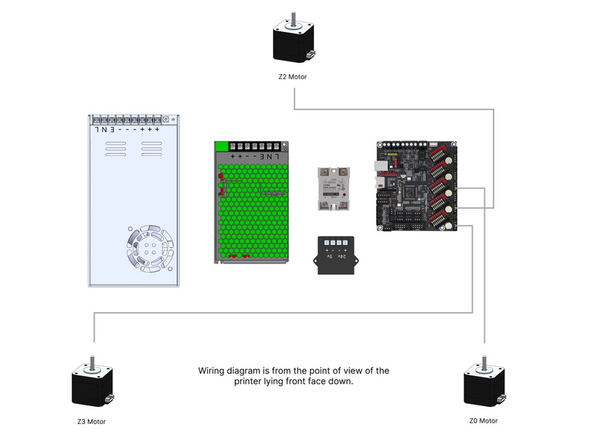

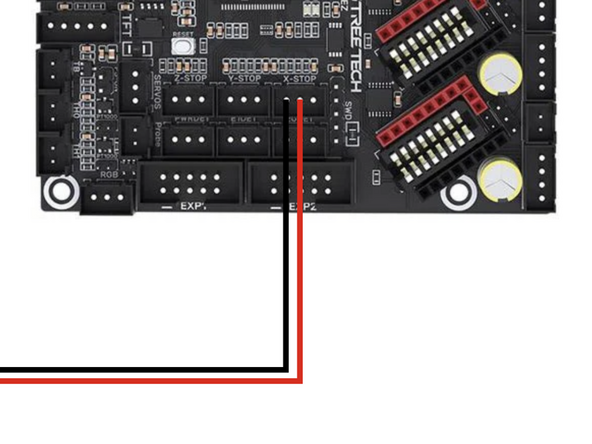

Wire the Z-motors as shown in the diagram.

-

The diagram is orientated to show you the position of the motors if the printer were lying front face down.

-

-

-

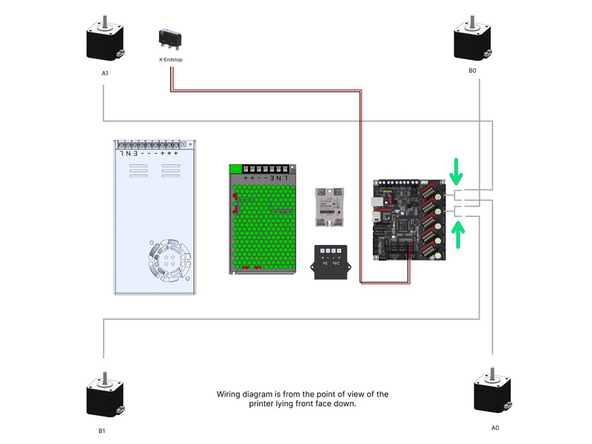

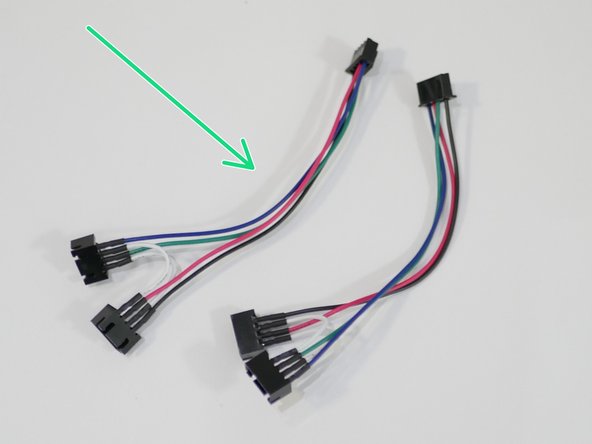

Wire the gantry motors and X-Endstop as shown.

-

Motor cable adapter

-

The diagram is orientated to show you the position of the motors if the printer were lying front face down.

-

-

-

Use the cable tie mounts and cable ties to clean up any loose or dangling cables.

-

-

-

Ready to move onto the next stage? Click here.

-

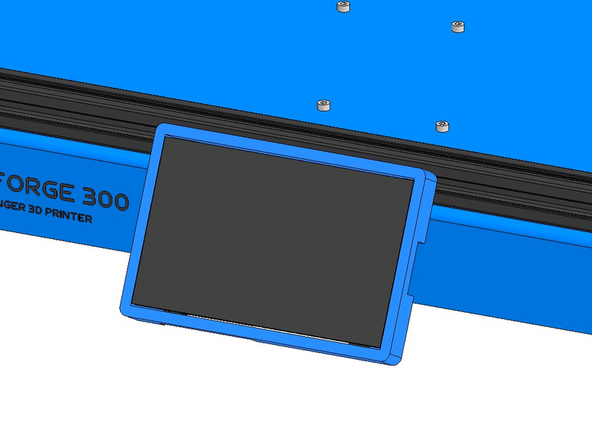

Don't have the Touch Screen upgrade? Skip to Stage 08: Klipper - Flashing.

-

Cancel: I did not complete this guide.

2 other people completed this guide.