-

-

Begin by downloading the following files/software:

-

Marlin Firmware

-

Touch Screen Firmware

-

USB Drivers

-

PrintRun - Printer Control Software

-

Download All Here

-

The downloads are in a compressed .zip format, you will need to use 7Zip to extract these files on PC.

-

-

-

You will also need to download and install the Arduino IDE.

-

-

Follow the install instructions and install the latest Arduino IDE software to your computer.

-

-

-

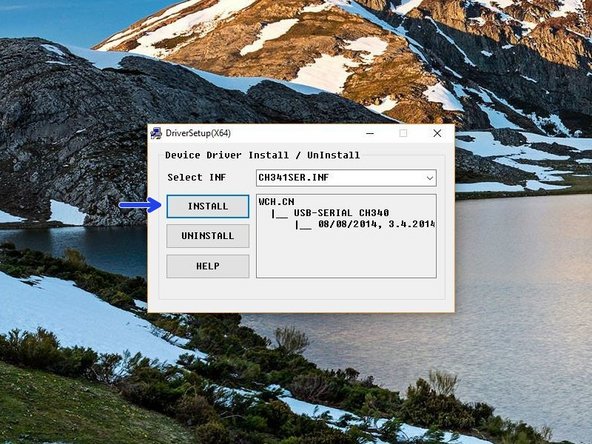

In the USB driver folder on PC double click on the CH341SER Driver - PC.EXE file. On MAC see the Readme.pdf file in the Mac folder.

-

You may need to right click, "run as admin" to open.

-

Once open, click INSTALL.

-

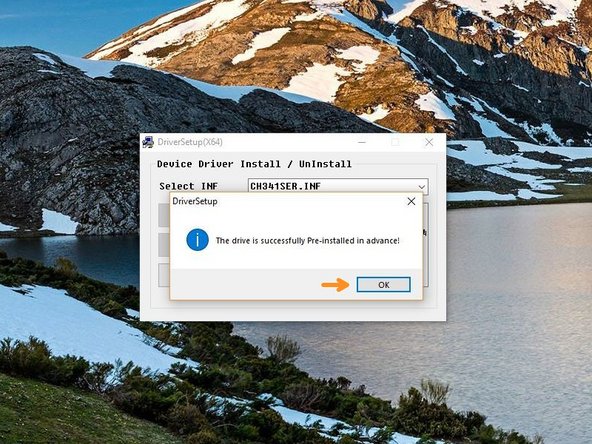

Once done, you should get a success message, click OK and close the programme.

-

-

-

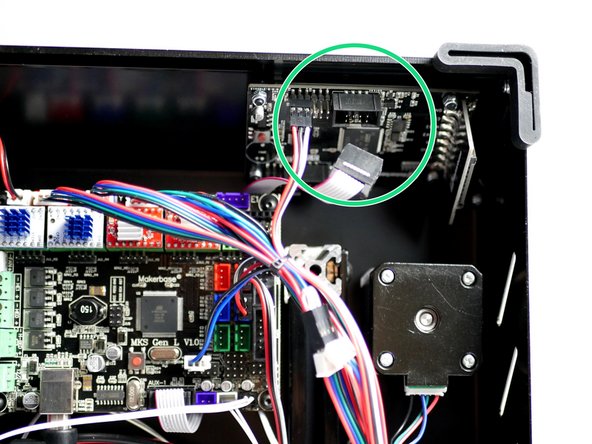

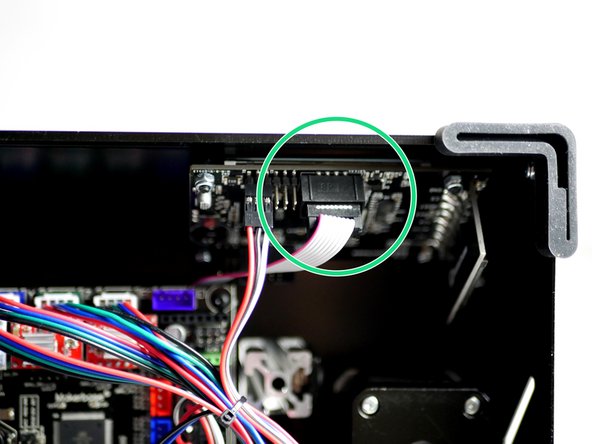

Disconnect the touch Screen display from the control board.

-

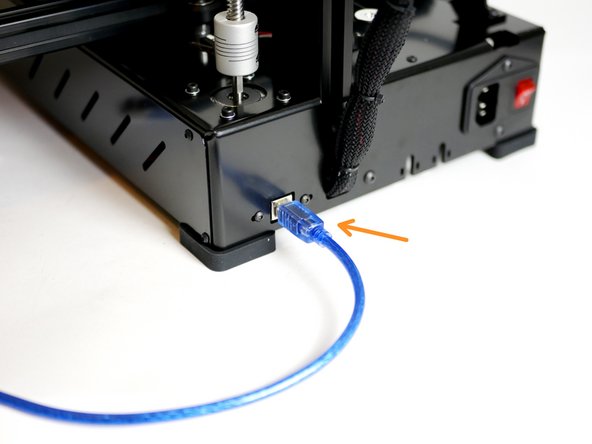

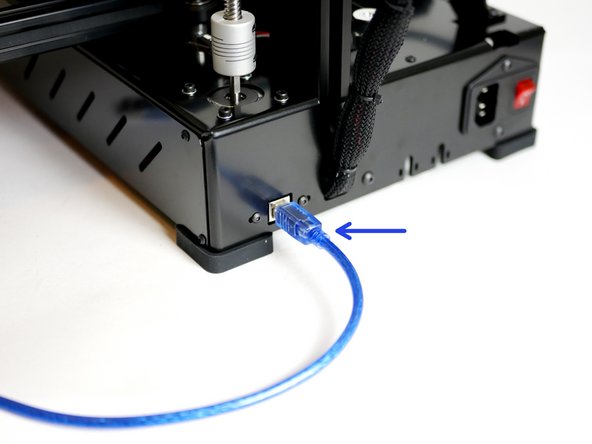

Connect the printer to your computer via the blue USB cable.

-

-

-

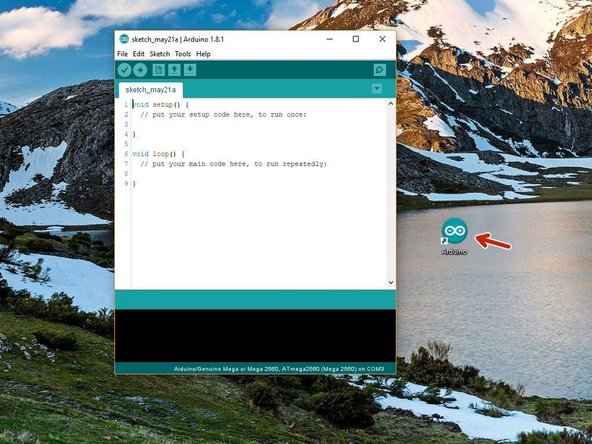

Open the Arduino IDE that you installed in step 2.

-

Right click, Run as Admin

-

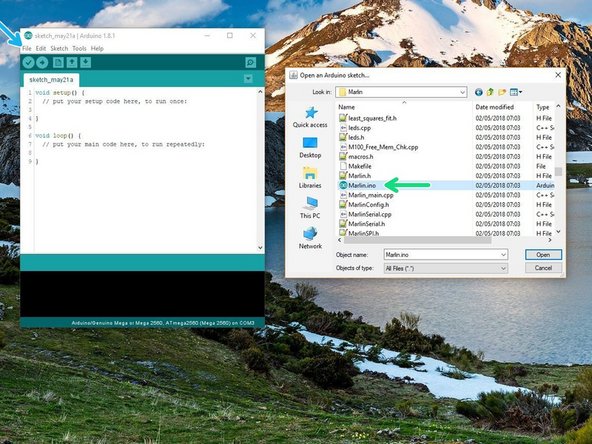

Go to File -> Open

-

Navigate to Marlin -> Marlin.ino in the Printer Firmware folder that you downloaded in step 1.

-

Select the correct firmware depending on whether you are building the Proforge 2 or 2S.

-

-

-

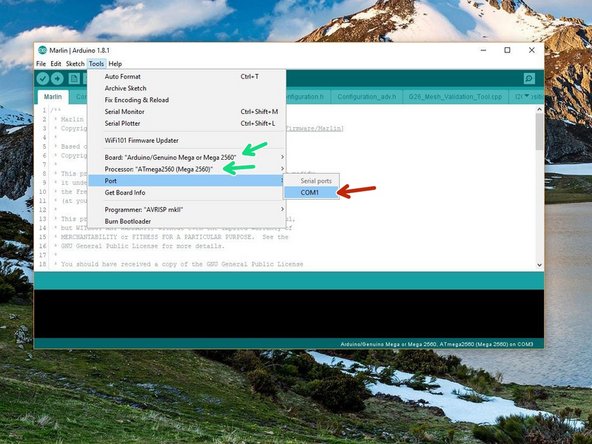

Go to Tools -> Port and select the port the Proforge 2/2S is connected to.

-

There should only be one but if you have others disconnect the Proforge from your computer to deduce the correct COM port.

-

Set the Board and Processor to Mega 2560

-

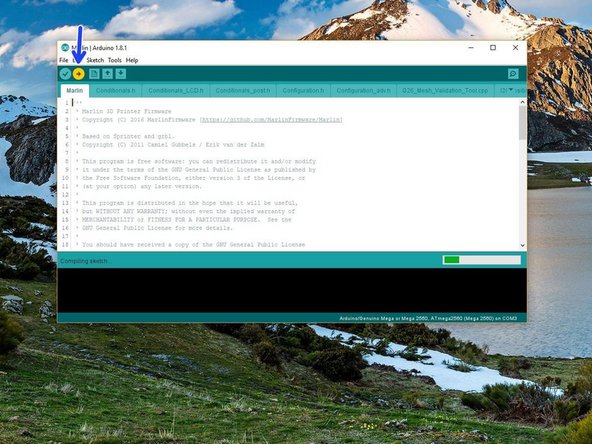

Click upload.

-

-

-

Once the firmware has done uploading keep the USB connected and power up the Proforge 2/2S via the mains power cable.

-

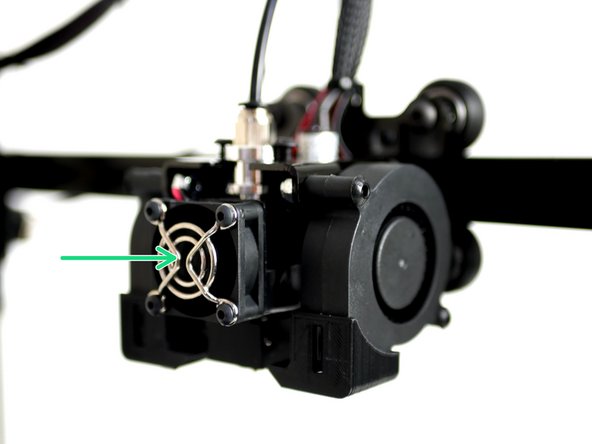

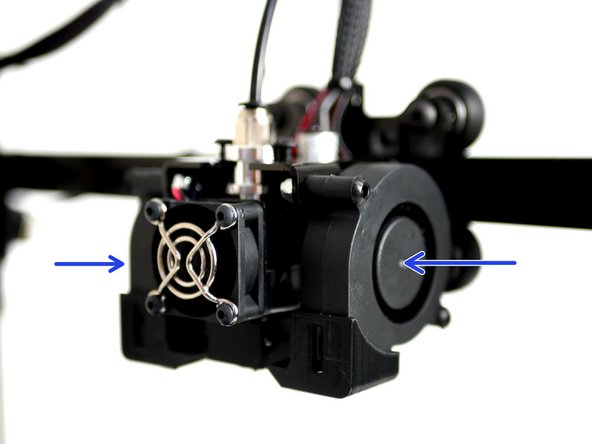

Check that the Hotend fan is spinning.

-

Check that the electronics fan is also spinning.

-

-

-

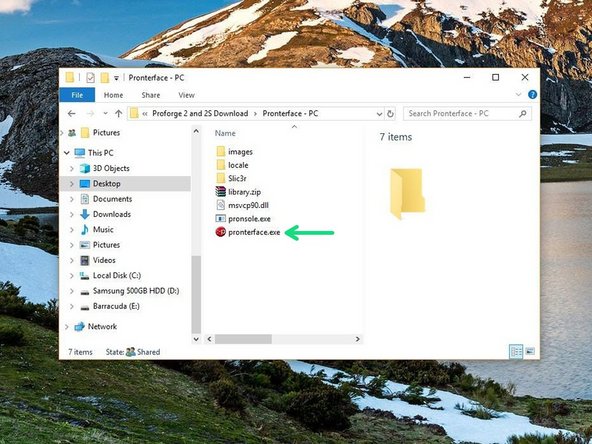

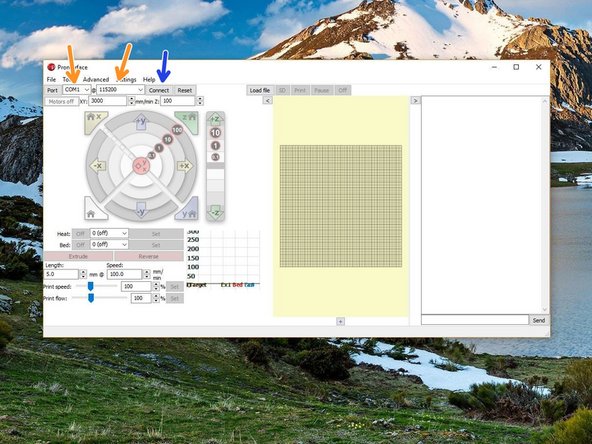

Launch Pronterface directly from its folder.

-

Select your COM port, and set the baudrate to 250000.

-

Connect to the Proforge 2/2S.

-

-

-

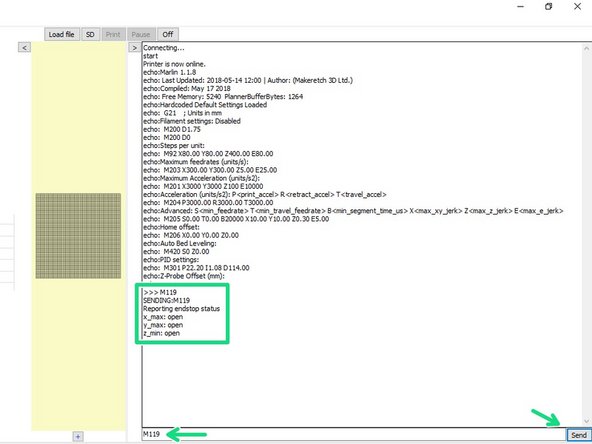

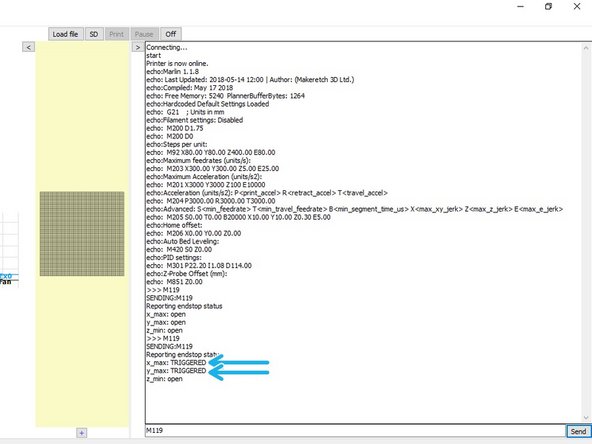

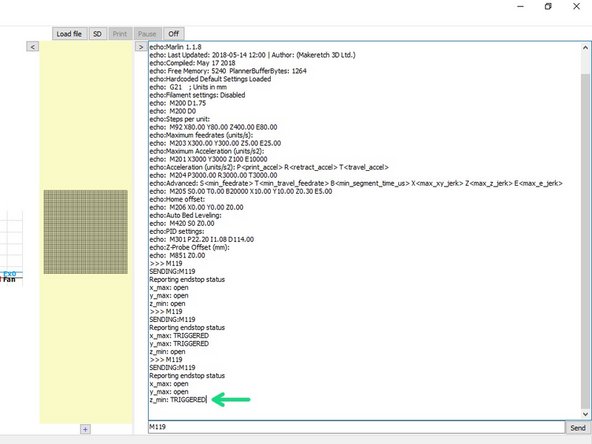

Once connected send an M119 command through the terminal on Pronterface.

-

It should read back open for both the endstops and probe.

-

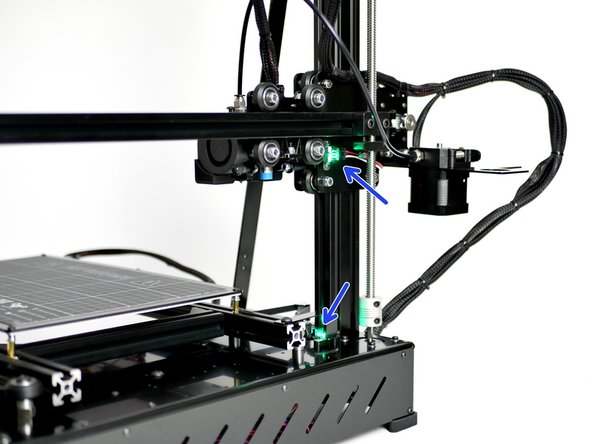

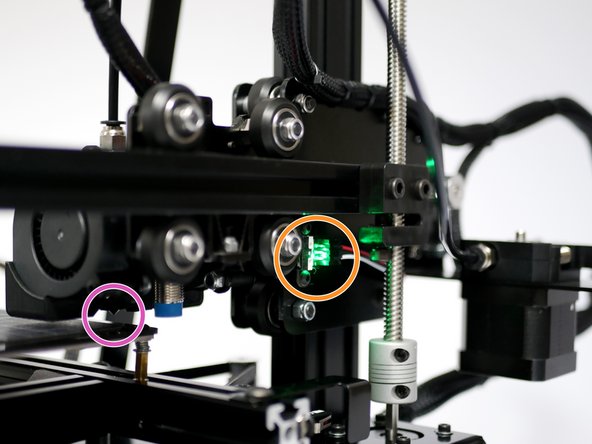

Move the axes so to trigger the X & Y endstops. A green light should shine.

-

Send the M119 command again - the X & Y endstops should return with a TRIGGERED message.

-

-

-

Whilst holding a metal object under the probe (a red light should shine) send the M119 command.

-

Pronterface should return: z_min: TRIGGERED.

-

-

-

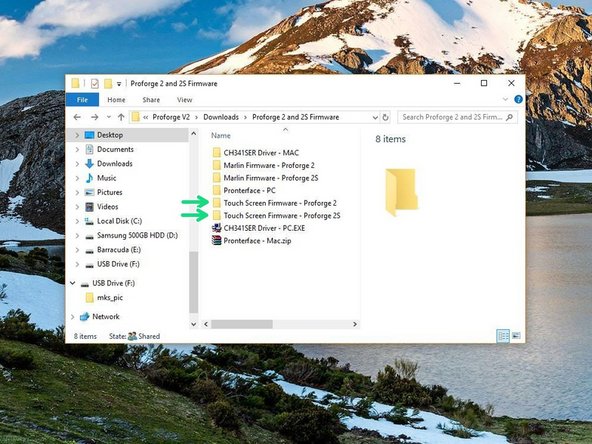

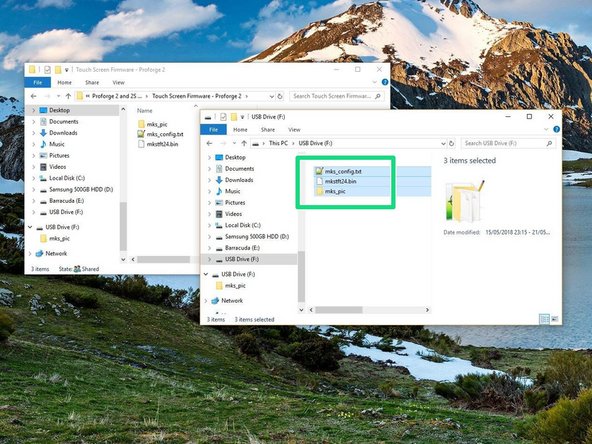

Copy the contents of the Touch Screen Firmware folder (depending on whether you're building a Proforge 2 or 2S) to the included SD card.

-

Make sure only the contents of the folder is on the SD card.

-

-

-

Power off the Printer and unplug the USB cable from the Proforge.

-

Reconnect the Touch Screen to the control board.

-

-

-

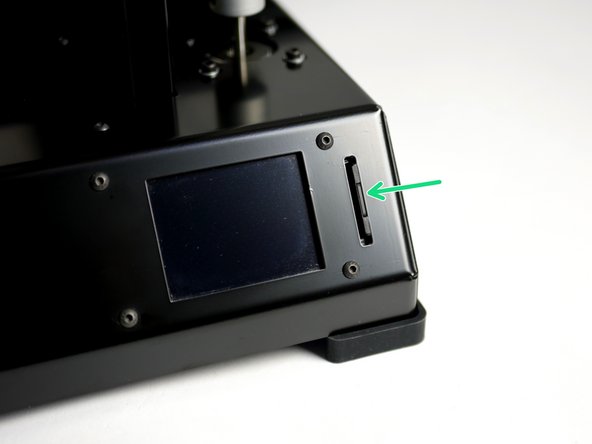

Insert the SD card (with Touch Screen Firmware on it) into the Proforge 2/2S.

-

Power up again the Proforge 2/2S. The Touch Screen display should now power up and begin installing the firmware immediately.

-

Wait for the install on the Touch Screen to finish, it should only take a minute.

-

-

-

Once done uploading you should have a screen that looks like this.

-

Check that you are getting correct temperature readings (Celsius), ie. room temperature.

-

-

-

Go to Settings -> Fan

-

Power up to 100%

-

Both of the blower fans should start running.

-

-

-

On the touch screen go to Tools -> Move.

-

Press the toggle switch to set motion to 10mm.

-

-

-

X-Axis: Pressing the right arrow will move the bed to the left, and vice versa.

-

This is correct as the nozzle position has moved to the right relative to the bed.

-

Y-Axis: Pressing the forward arrow will move the hotend towards the endstop and vice versa.

-

Z-Axis: Pressing the double up arrow will move the gantry up and vice versa.

-

You will not be able to move to a negative position from your original starting position - this is normal.

-

-

-

Using the touch screen go to Tools -> Home.

-

Home X

-

With X homed the nozzle should land above the right edge of the print surface.

-

If you find the nozzle not lining up correctly in the X direction adjust the endstop trigger to achieve better alignment. The distance between the end of the beam and the edge of the metal part should be approximately 6mm.

-

-

-

Home Y

-

The nozzle should land about 1cm from the top edge of the print surface, this is OK.

-

-

-

If you have the Flexplate upgrade make sure it is on the platform before starting.

-

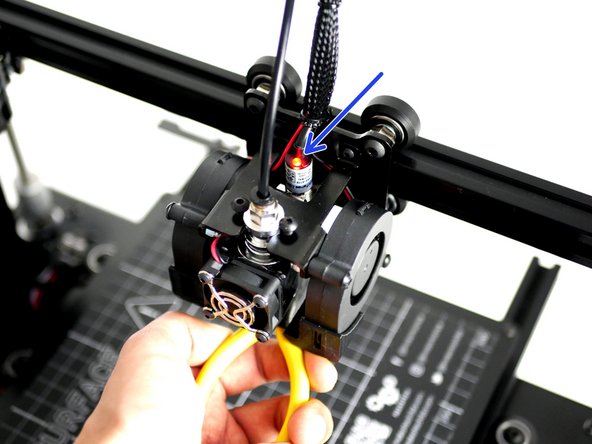

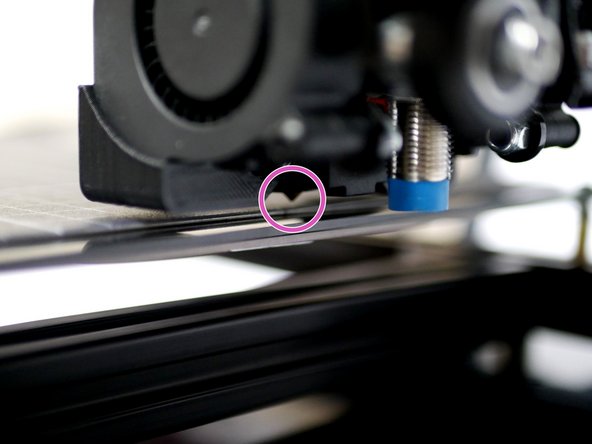

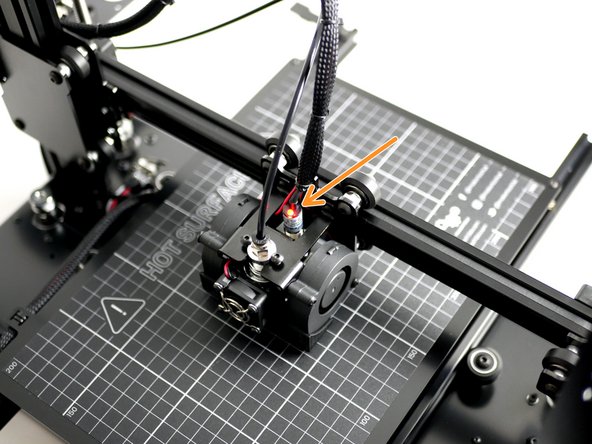

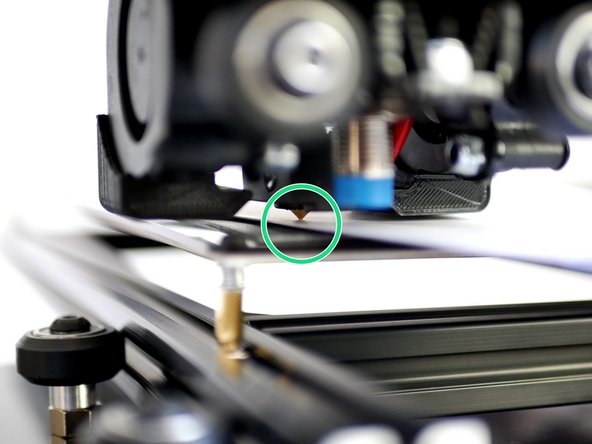

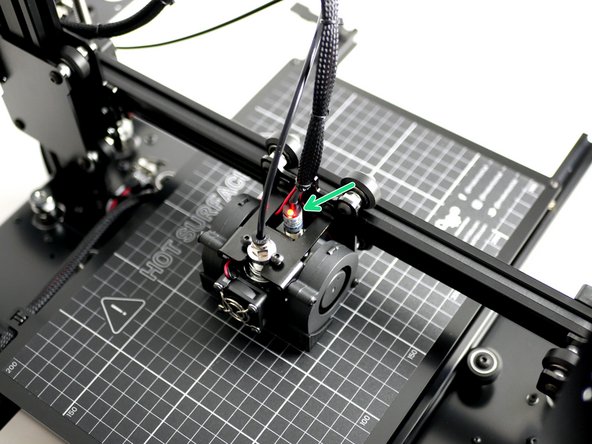

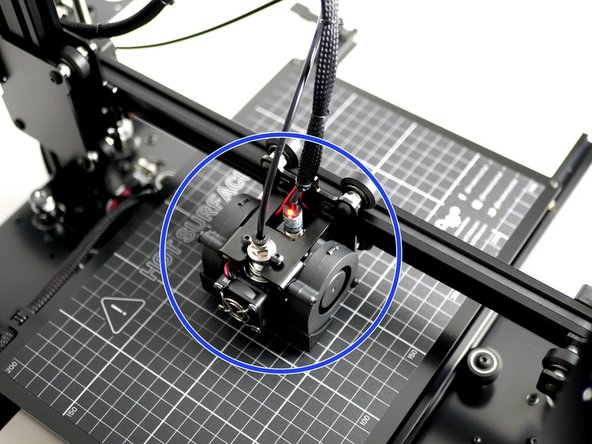

Lower the gantry so that the nozzle comes close to the print surface. Once close enough the red light on the probe should come on.

-

The nozzle tip should always remain above the surface when the probe is triggered. The bottom of the probe should always remain above the tip of the nozzle.

-

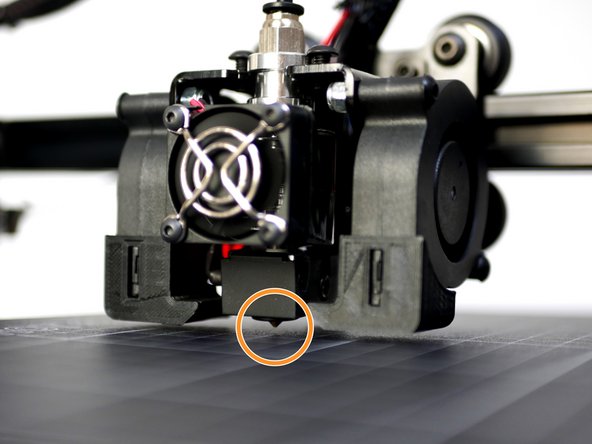

Nozzle too close or hits the print surface before the red light on the probe comes on:

-

Lower the probes position on the mount and check again.

-

Red light on probe but nozzle tip is too far away from the print surface:

-

Raise the probes position on the mount and check again.

-

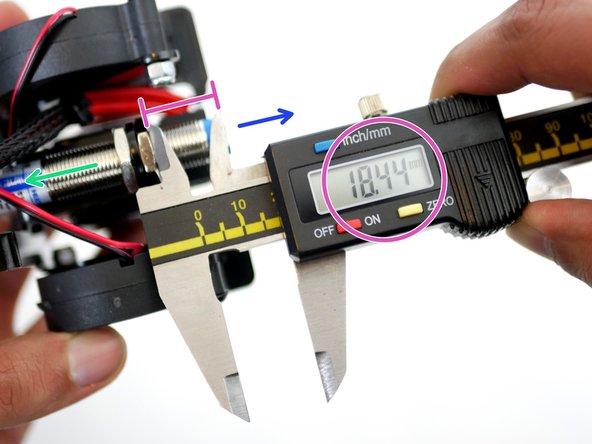

The optimal position of the probe is around 18mm from the bottom of the probe and the bottom of the lower nut as shown in the 3rd image.

-

-

-

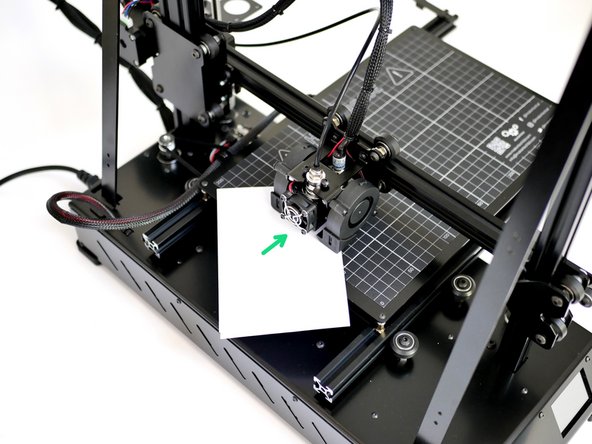

The Proforge 2/2S features automatic bed-levelling but to help get more accurate results we need to first make sure that the bed is physically as level as it can be.

-

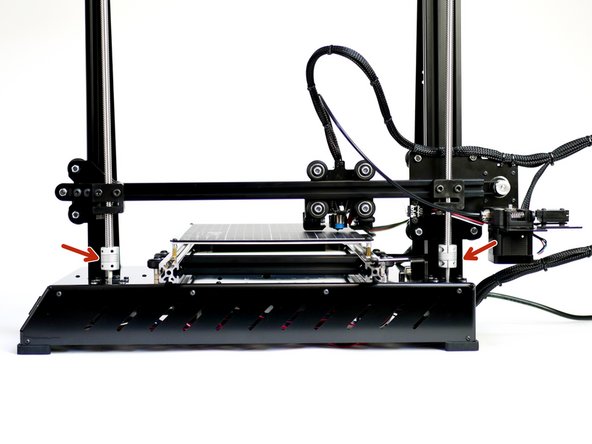

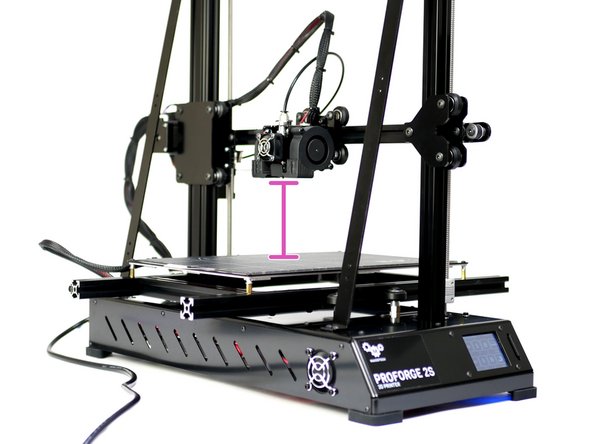

Adjust the z-motors so to get the distance between the nozzle and print surface along the y-axis (gantry) equal.

-

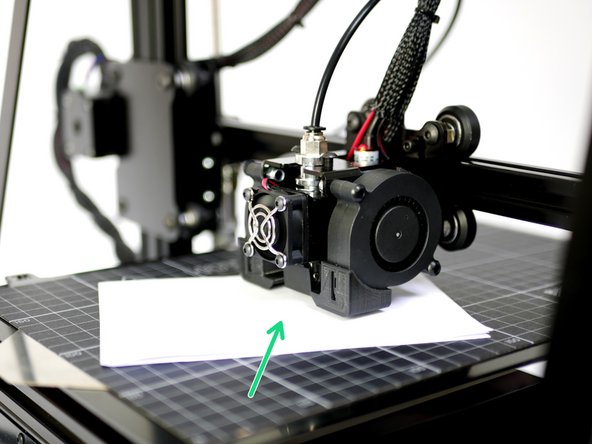

Use a folded piece of paper to feel the gap between the nozzle and print surface.

-

-

-

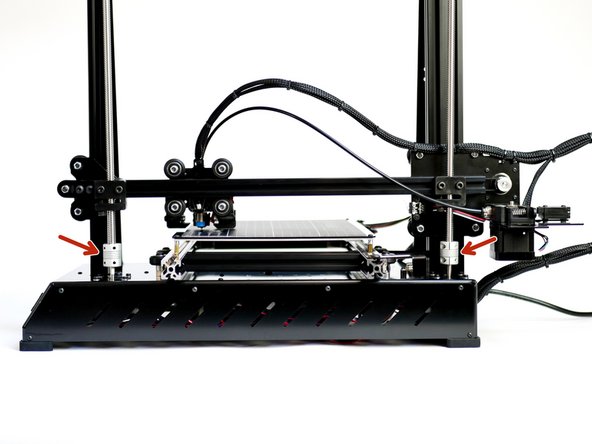

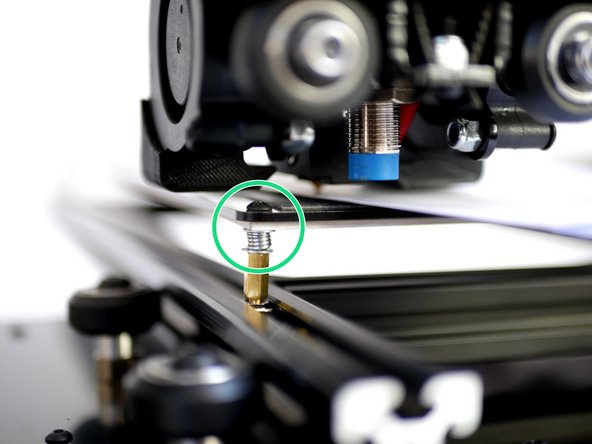

Next use the springs on the platform to level the print surface in the X-direction (or both the X & Y direction if you're building the Proforge 2).

-

Turn the screw anti-clockwise to raise that corner of the platform.

-

Use a folded piece of paper to feel the gap between the nozzle and print surface.

-

-

-

To check that the probe and bed is set up correctly we are going to Home all of the axes together.

-

Using the touch screen go to tools -> Home -> Home All

-

X & Y will automatically home first. Then the probe should move to the centre of the platform and slowly lower until it's triggered.

-

The gantry will go up at first and then begin lowering - this is normal.

-

Have your finger ready on the power switch to power off in the event of a crash. If you do crash the hotend into the platform re-check your probe postioning - it's likely too far above the nozzle and needs lowering.

-

-

-

With a successful Z Home go to Tools -> auto-level. Press ONCE.

-

The axes will home again and the sensor will now go around the platform probing 9 points.

-

Again, have your finger ready on the power switch to power off in the event of a crash.

-

Once the Auto-levelling has been completed, re-home all of the axes to return the nozzle to the centre of the platform.

-

-

-

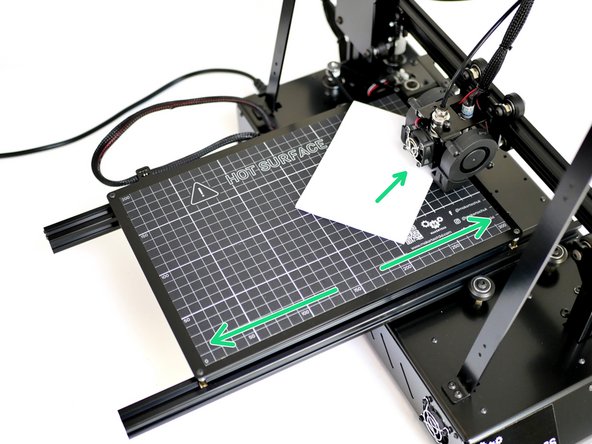

Take the folded piece of paper and place between the surface and nozzle.

-

On the touch screen go to Tools -> Move and toggle the distance selector to 0.1mm.

-

Use the touch screen display to lower the nozzle (z-axis) in 0.1mm increments until it begins to grip the paper.

-

Make a note of the Z height displayed on the top right of the touch screen when the paper begins to be gripped. (This value will be 3.00mm to begin with, this is normal.)

-

In this case it ended up being 1.50mm when the paper began to be gripped, but this value will be different for everyone.

-

When done raise the nozzle up about 80mm.

-

-

-

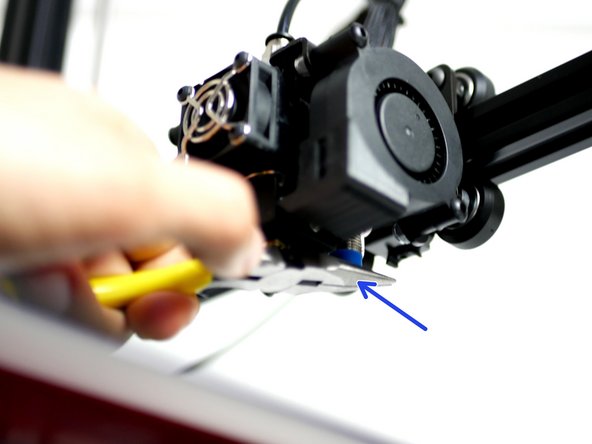

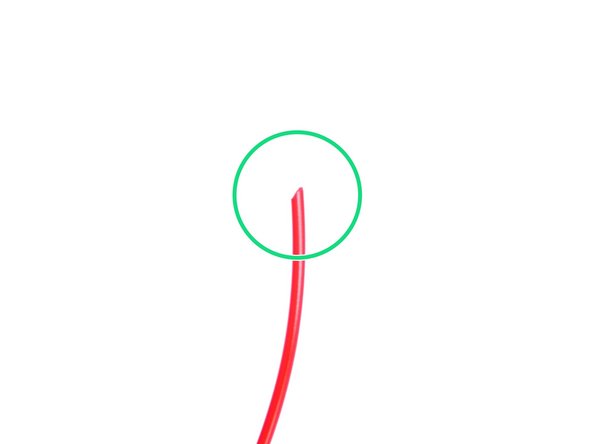

Take the included sample of PLA filament out of its packaging.

-

Use the included pliers to cut a sharp end.

-

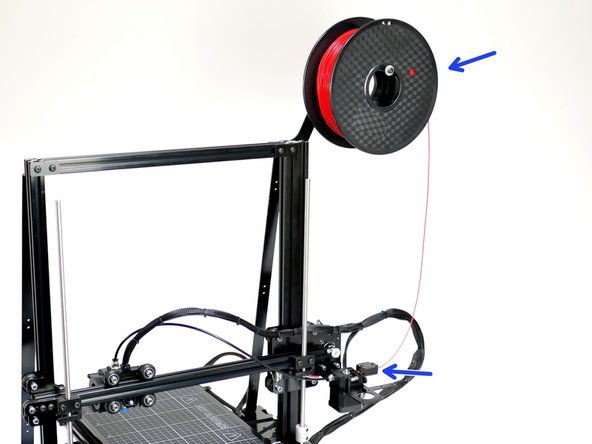

Place the spool of filament onto the spool holder and feed the filament through the filament sensor.

-

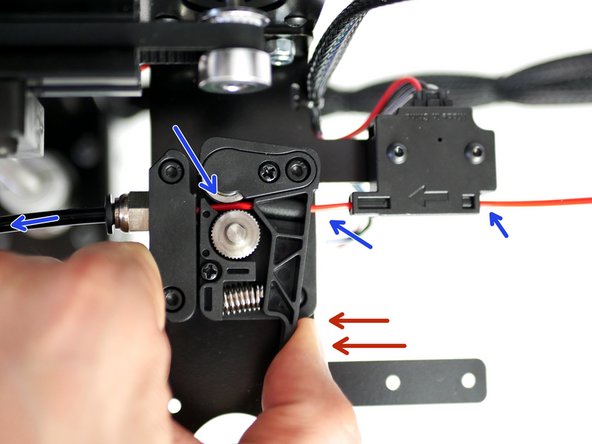

Press down the Idler arm and push the filament in through the feeder and through the PTFE tubing until it reaches the Hotend.

-

-

-

On the touch screen go to Tools -> Preheat

-

Heat the Hotend up to 200C.

-

Wait for the Hotend to heat up.

-

Caution - the Hotend will cause burns if touched while hot!!!

-

-

-

With the Hotend up to temp and the filament loaded, go to Tools -> Extrusion.

-

This is the length of filament that will be fed, each time you tap the down arrow.

-

This is the speed setting.

-

You should have a smooth and continuous flow of plastic coming out of the Hotend nozzle.

-

The extruded plastic will be hot!

-

NOTE: When powering down from a hot Hotend, power the hotend down first and let it cool to at least 100C before completely powering off - as this prevents the heat from rising up the hotend with the absense of the fan cooling it.

-

-

-

Go to Tools -> Preheat

-

Press the extruder icon to toggle to the bed.

-

Power on the bed by setting its temperature to 60C - typical for PLA printing.

-

The bed should begin to heat up.

-

Do not touch the bed when hot!!!

-