-

-

Use two M2.5 x 6mm bolts to fix the servo onto the backplate.

-

Make sure that the servo shaft is centrally aligned with the backplate.

-

-

-

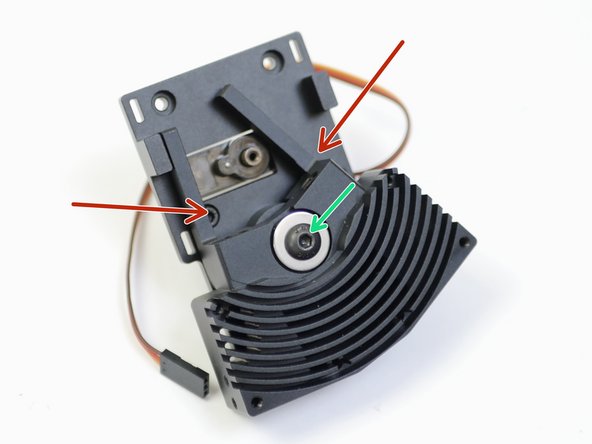

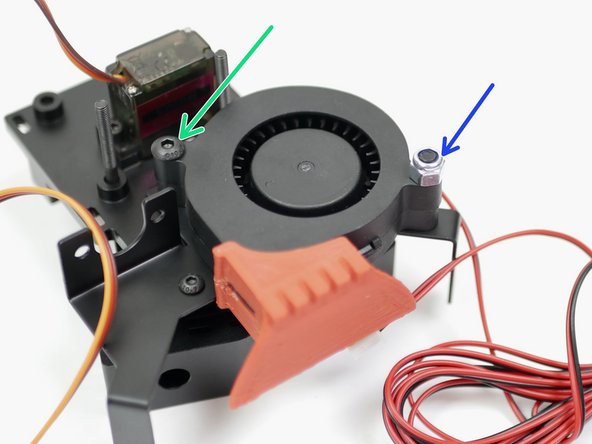

Insert an M5 x 20mm bolt with a needle bearing and shim.

-

M5 x 20mm Bolt

-

Thrust Bearing

-

Shim

-

On the other side of the heatsink slide on another thrust bearing.

-

-

-

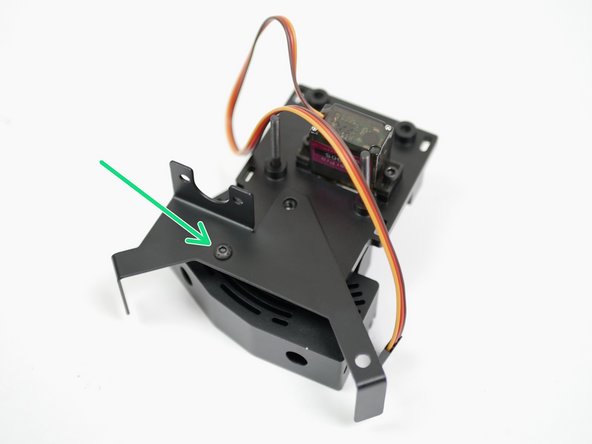

Begin by preparing the backplate with two M3 x 30mm bolts as shown.

-

Drop an M5 nut into the back of the Backplate.

-

Fix the assembly together, making sure that there is no play in the switching motion.

-

The bolt should be tightened down enough to allow the heatsink to rock, but there shouldn't be any play along the axis of rotation or on the plane of contact.

-

-

-

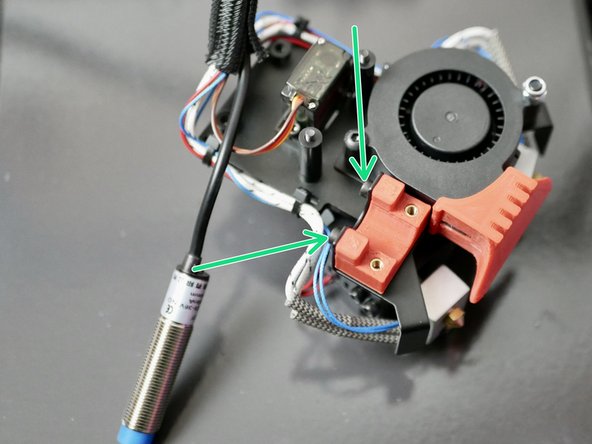

Fix the Probe and Fan mount onto the back of the backplate with an M3 x 6mm button head bolt.

-

This will be an M2.5 x 6mm bolt on v2.1 Switching Hotends.

-

-

-

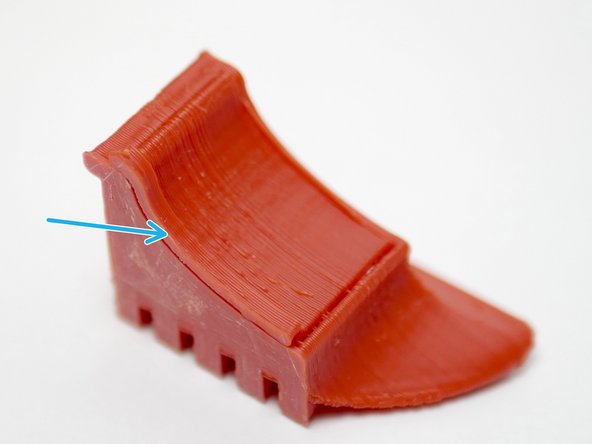

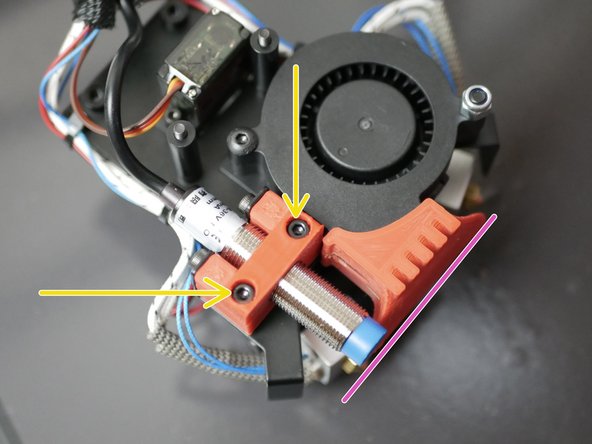

The part cooling fan shroud is a 3D-printed ABS part. Begin by removing the support with a pair of pliers by pulling on the tab.

-

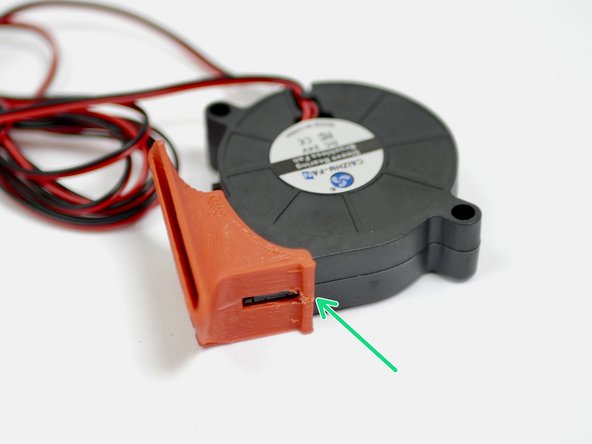

Fix the fan shroud onto the blower fan. The fan shroud is designed to snap in place.

-

-

-

Fix onto the Backplate with an M4x22mm

-

Fix onto the Probe and Fan Mount with an M4 x 22mm bolt and M4 Nyloc nut.

-

-

-

Fix the 3D printed probe mount to the metal mount like shown with two M3 x 6mm bolts.

-

Remove the nuts and washers from the probe and fix the probe to the mount, again with two M3 x 6mm bolts.

-

Adjust the probe so that the bottom of it is level with the bottom of the fan shroud, like shown.

-

Note, we've had to back track a little here, that's why more of the assembly is done in the images.

-

-

-

The v2.1 update replaced the 3d printed mount with a CNC'd Aluminum one.

-

Mount it using two M2.5 x 6mm bolts.

-

Secure the probe to it using another M2.5 x 6mm bolt.

-

-

-

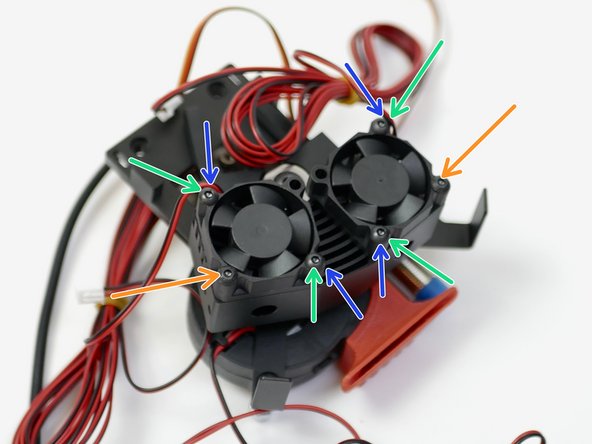

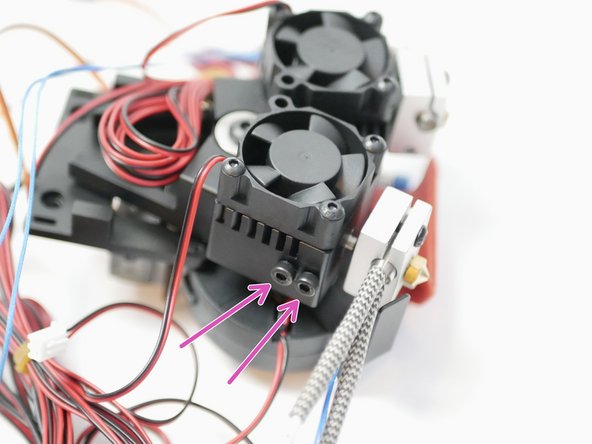

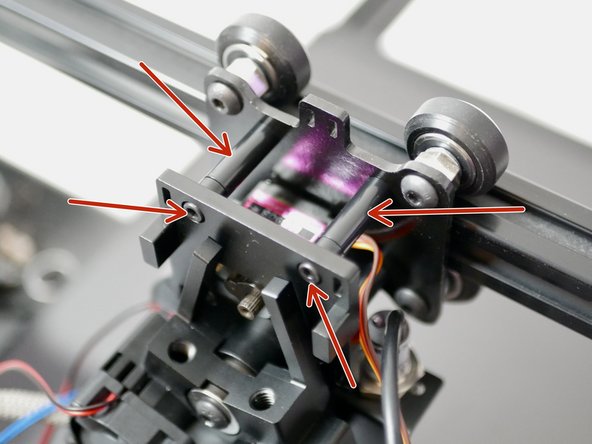

Fix the two 30mm fans onto the heatsink. Orientate the cables as shown.

-

M3 x 20mm bolt

-

M3 x 12mm bolt

-

The V2.1 update uses the following bolts in only these locations:

-

M3 x 30mm Cap Head Bolt

-

-

-

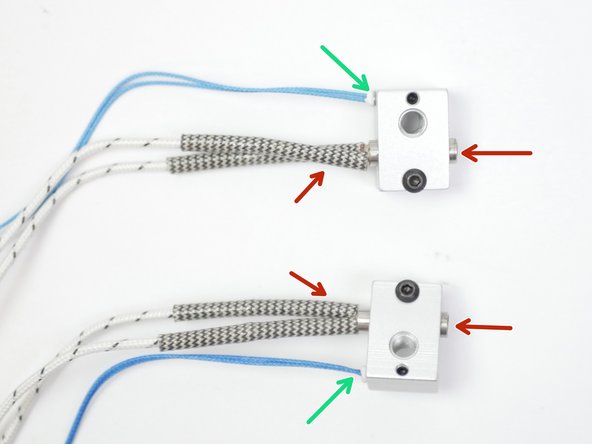

Take the two heater blocks and fix into them the two heater cartridges as shown.

-

Fix two thermistors to the blocks. We've shown two high temp. thermistors being installed here, but it is identical for the low temp thermistors too.

-

Make sure to match the orientation as shown in the photos. The two assemblies should mirror eachother.

-

-

-

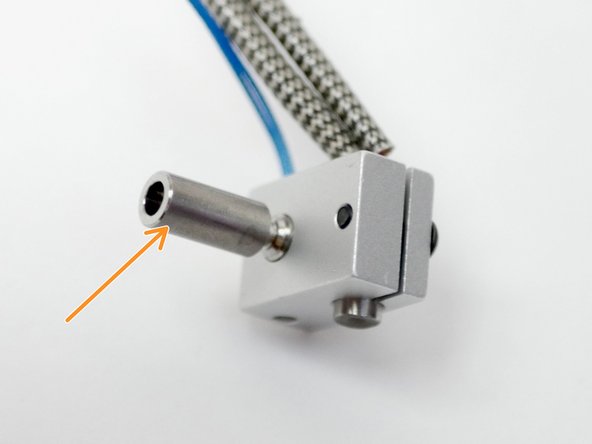

Fix onto both the heater blocks, the heat-break.

-

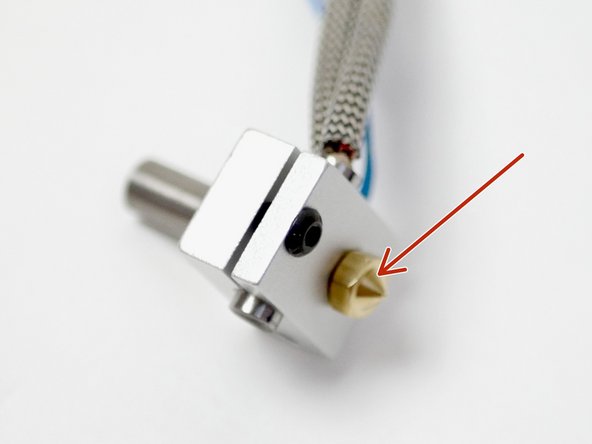

and the nozzle.

-

The v2.1 Update will also include a Copper/Titanium heat-break. It is installed in the same way.

-

Make sure that the nozzle is tight against the heatbreak, but leave a slight gap between the nozzle and heater block when tightening. The nozzle will need to be tightened again when hot.

-

-

-

Take the two heater block assemblies from the previous step and install them into the heatsink.

-

Fix the heater block assemblies in place with two M3 x 12mm bolts. Make sure that the bottom of the heartbreak lines up with the face of the heatsink. The height will be adjusted later to match your print platform.

-

Note the orientation in the image. The heater side of the block should be facing forward.

-

-

-

Mount the assembly to your printer's tool carriage with four M3 x 30mm bolts and four M3 x 20mm spacers.

-

We are showing it being mounted onto the 2020 tool carriage from the Proforge 2S.

-

Tighten the bolts by beginning with the bottom two, you will have to tighten each one slightly, in turn, to prevent it from getting jammed up on the heatsink's horns.

-

-

-

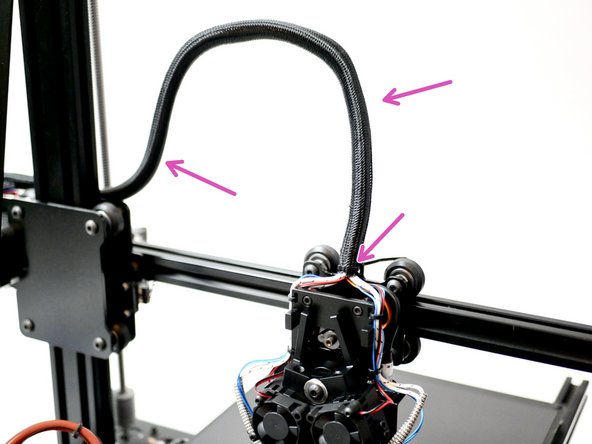

Take the heater assembly cables and route them along the sides of the backplate. Use cable ties to secure them in place like shown.

-

Heater, thermistor, 30mm fan cables.

-

Before firmly securing the cable ties, make sure that there is enough slack in the cables to allow the hotend to pivot.

-

Take the probe, blower fan and servo cables and point them upwards.

-

-

-

Fix the servo extension cable to the servo's cable. Make a note of the cable's orientation.

-

Finally, use the braided cable sleeving to wrap the cables and route them down to your electronics main board.

-

-

-

Adjust the ooze shields by bending the metal sleds until they are able to make contact with the tips of both nozzles.

-

-

-

The Hotend covers simply slide in place over the heater blocks.

-

Almost done!

Finish Line