-

-

Check that you have all of the following:

-

3D Printed Parts (x4)

-

Rails (x4)

-

Fastener pack

-

5x8 Coupling

-

M4 Threaded Inserts (x11)

-

You will also need (not included):

-

Allen keys, Drill with metal bits (2mm/3mm), Side Cutters, Pliers, Soldering Iron (for threaded inserts)

-

-

-

Begin by disassembling the platform from the base.

-

Do this by first untying the belt from the platform.

-

Then remove the heated bed and place it to one side, you don't need to disconnect its wiring.

-

If you have the Pi Camera installed, unmount it also, again you don't need to disconnect it from the pi board.

-

Finally, remove the old HDPE linear guides holding the platform in place.

-

The platform should now be free for the next step of drilling the holes for the linear rails.

-

-

-

Next, remove the tool carriage and Y-belt from the gantry. Do not cut the belt, it will be re-used.

-

Free the y-endstop from the gantry.

-

The lead screw bracket at the top of the printer can also be removed, this part can be disregarded as it won't be re-used.

-

Disconnect the y-motor from its cable.

-

Use side cutters to break the cable ties holding the cables to the gantry.

-

Free the lead screw coupling from the z-motor shaft.

-

Finally remove the HDPE linear guides from the gantry and the entire gantry part should now be free.

-

-

-

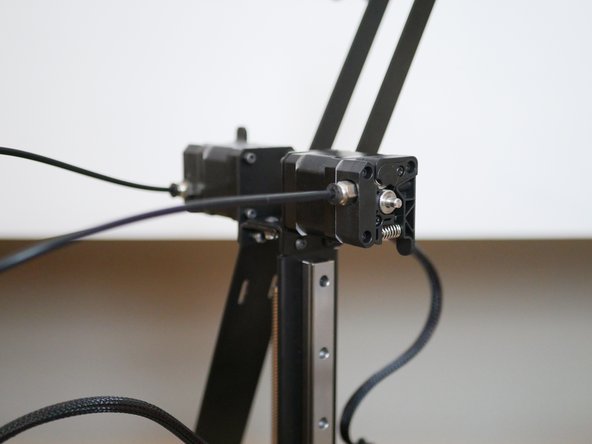

If you have an extruder installed on the vertical pillar, remove it now.

-

Next, unfasten the bolts connecting the pillar to the support bracket at the top of the pillar.

-

Remove the the motor bolts at the bottom of the pillar.

-

The pillar should now come free.

-

-

-

Use a 2mm metal drill to create 3 holes on either side of the platform.

-

Place one of the 40cm rails on the platform, 4mm +/-1mm from the edge.

-

Use a pencil to mark out where you are going to drill.

-

Secure the rail as shown with three M2 x 10mm bolts and M2 Nyloc Nuts

-

Be very careful with the carriage, either secure or remove them very carefully. If they fall off and are hit, the ball bearings inside them will escape!

-

-

-

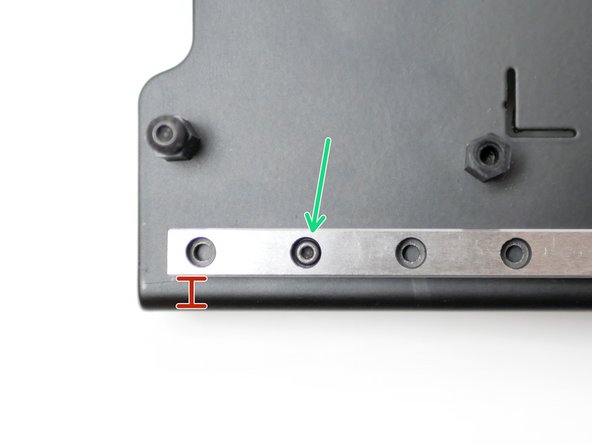

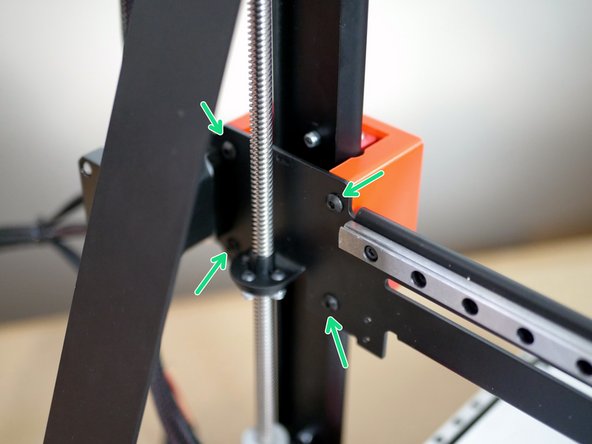

Use a 3mm bit to drill three holes into the gantry.

-

The rail should be fitted 5mm from the top edge of the gantry.

-

Secure with M3 x 12mm Cap and M3 Nyloc Nut

-

-

-

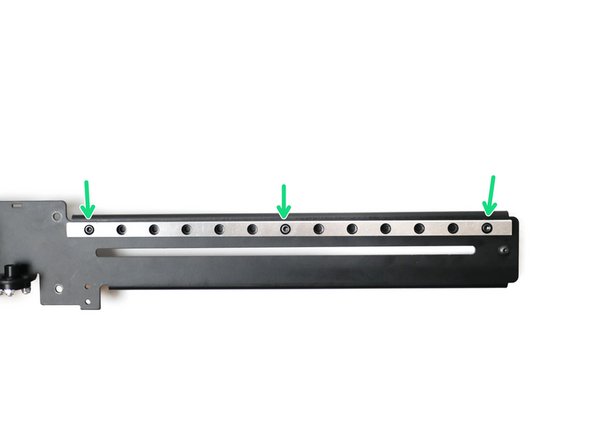

Align the thicker 15mm rail to the centre of the pillar and create marks for three holes.

-

Drill three 3mm holes into the pillar.

-

Secure the rail with three M3 x 12mm cap bolts and M3 nyloc nuts.

-

Re-install the z-pillar when done.

-

-

-

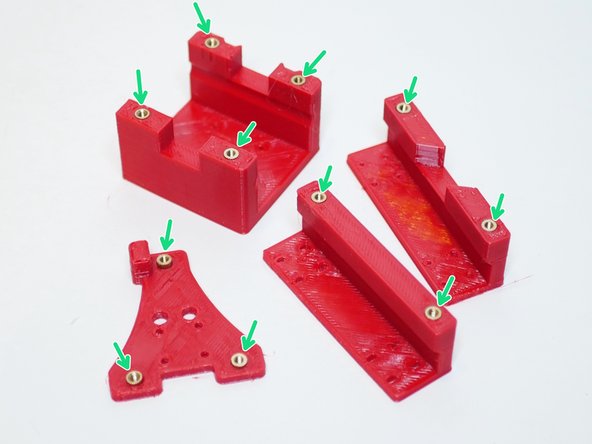

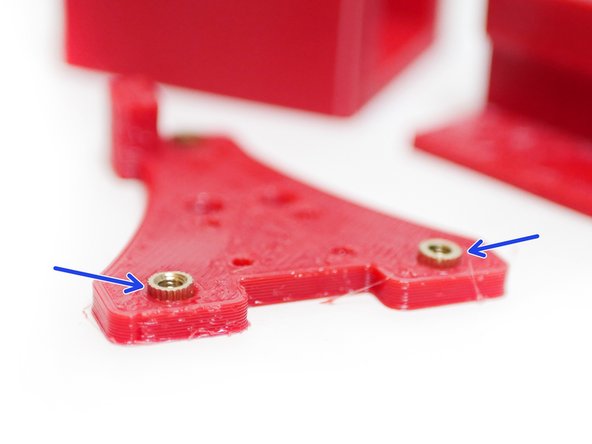

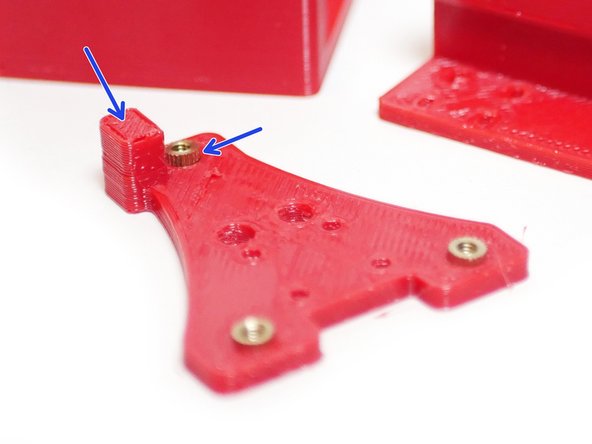

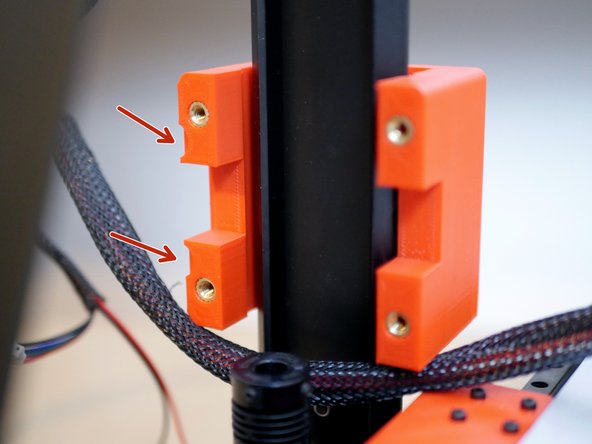

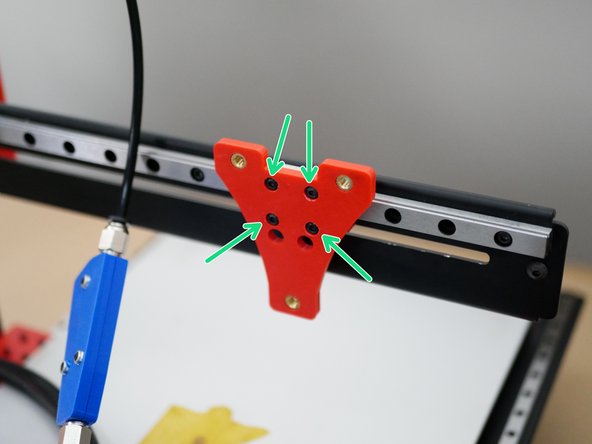

Using a soldering iron push the threaded inserts into the 3D printed parts as shown.

-

M4 Threaded Insert

-

Note that the inserts on the Tool Carriage part need to protrude out on the side shown.

-

-

-

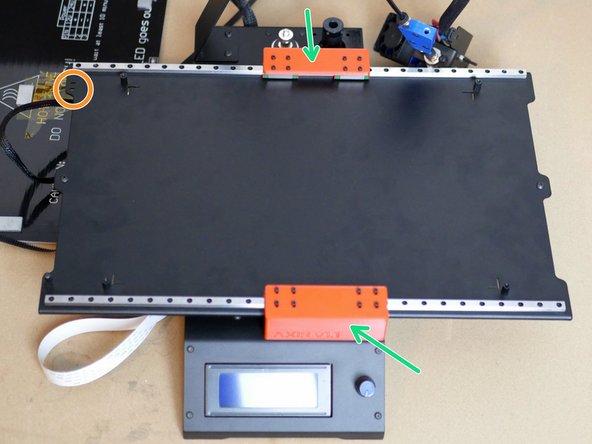

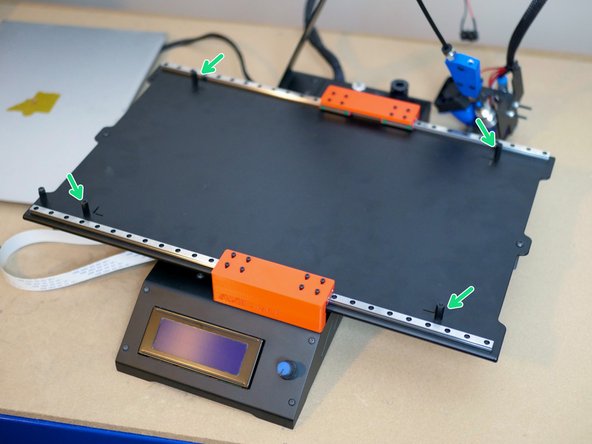

Begin by installing the two 3D printed parts to the Base with two M4 x 6mm Bolts.

-

Next line up the linear rail carriages on the platform with the holes on the 3d printed brackets.

-

Secure the platform to the brackets using M2 x 6mm cap bolts.

-

Double check you have the correct orientation, the heated bed cable relief mount should be in the top left.

-

-

-

A heated bed is required for this upgrade to properly work.

-

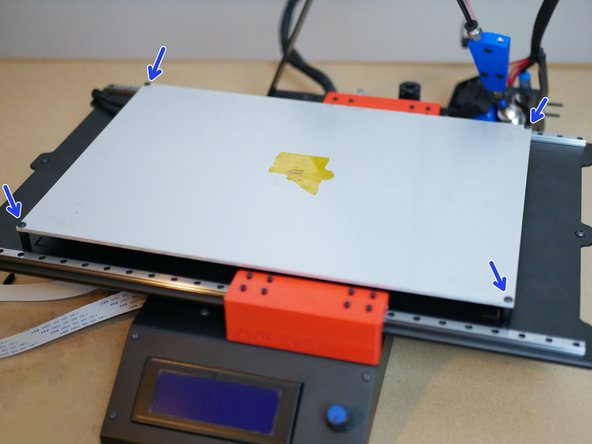

The heated bed needs to be raised 5mm before it can be installed. To do this we replace the 10mm stand-offs with 15mm ones.

-

With the 15mm stand-offs installed, re-mount the heated bed.

-

-

-

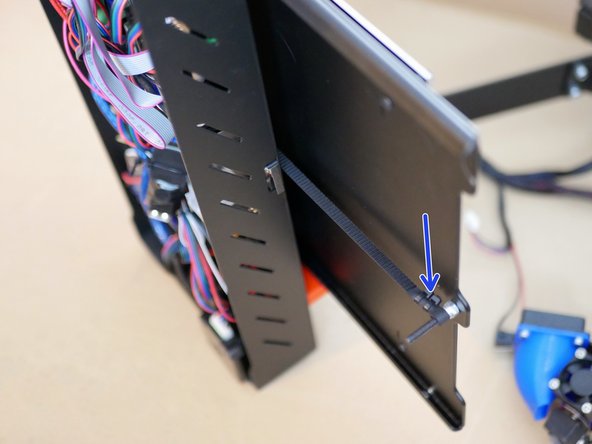

Re-install the belt by first wrapping it around the pulley on the motor and then feeding it in through the rear bracket and around the bearings.

-

You will need to use a pen to guide the belt around the bearings.

-

Secure the belt to the bolts on the ends of the platform.

-

Re-attach the Pi-cam if you have that upgrade.

-

-

-

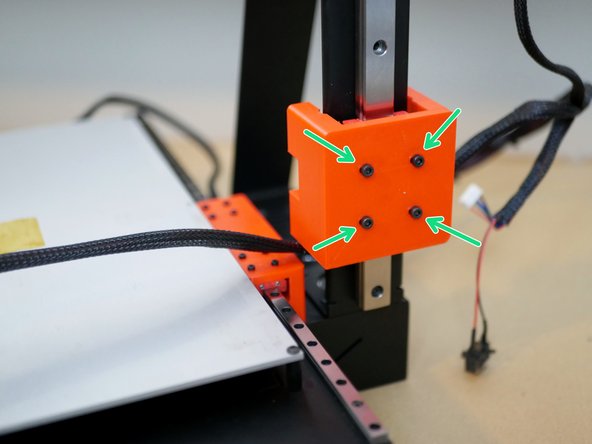

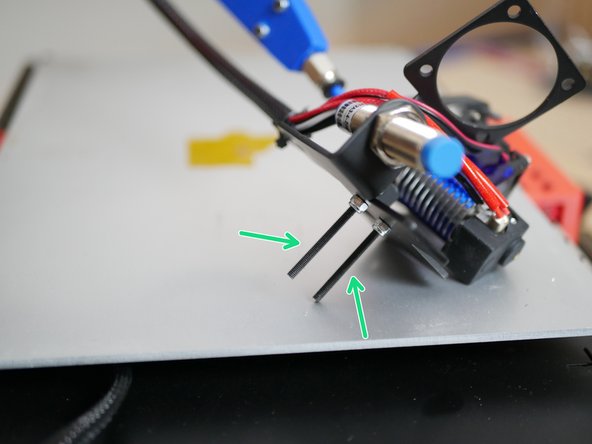

Fix the gantry carriage to the Z-Rail as shown with four M3 x 8mm cap head bolts.

-

Note the orientation of the carriage. The side with the small insets should point towards the rear of the printer.

-

-

-

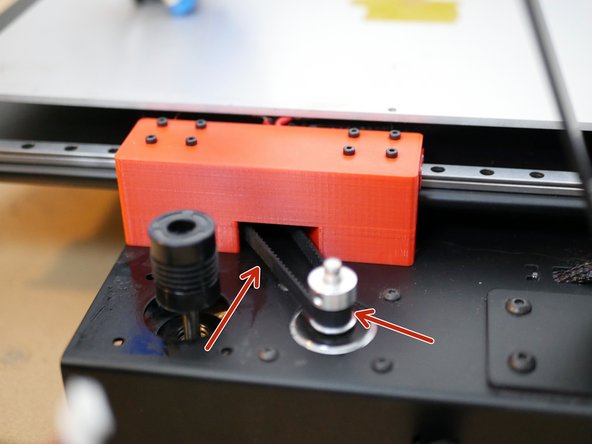

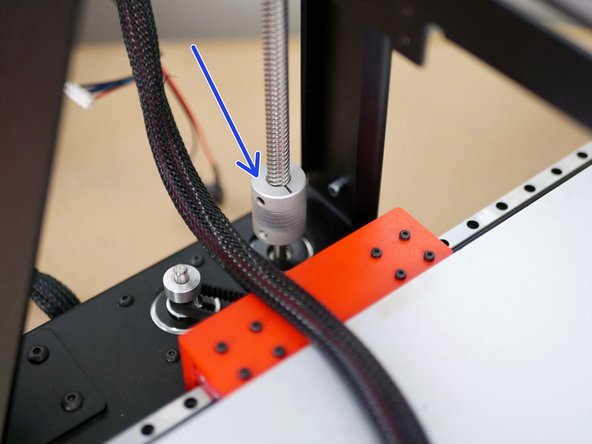

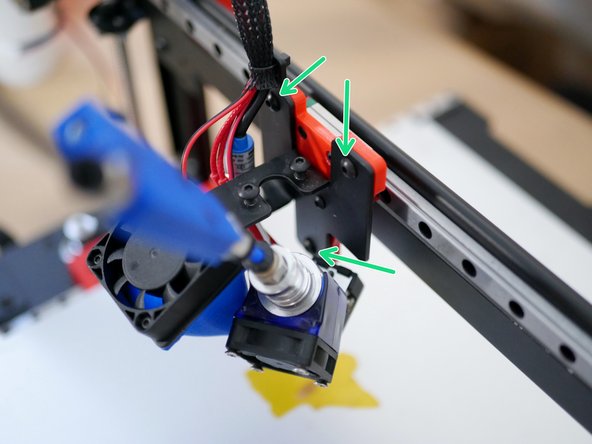

Re-attach the the lead screw to the gantry.

-

Next fix the coupling to the z-motor shaft.

-

Finally, fix the gantry to the carriage with four M4 x 6mm bolts.

-

You can also now reattach the end stop and cables.

-

-

-

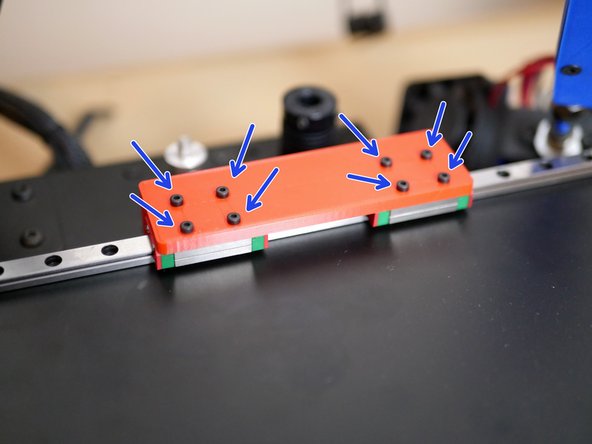

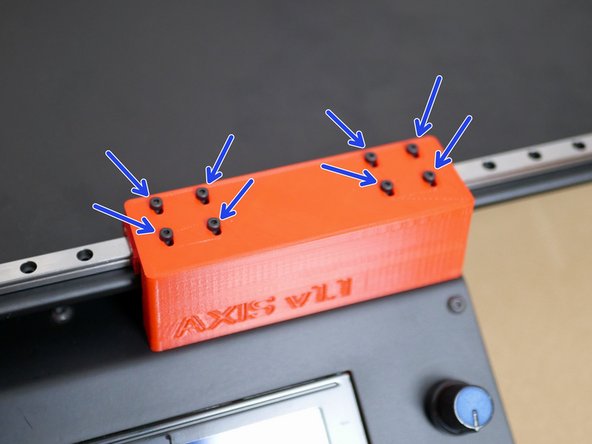

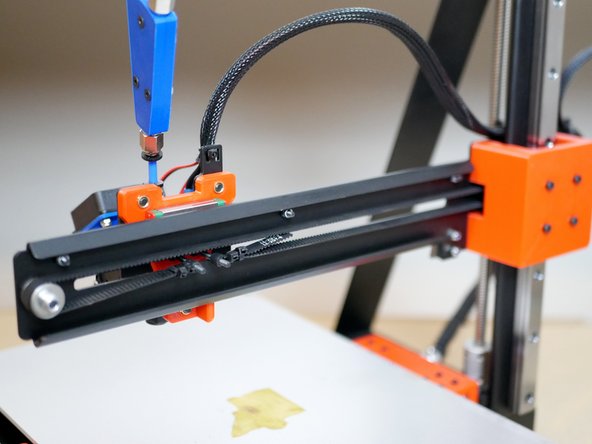

Fix the 3D printed tool carriage to the gantry rail.

-

M3 x 6mm button head

-

-

-

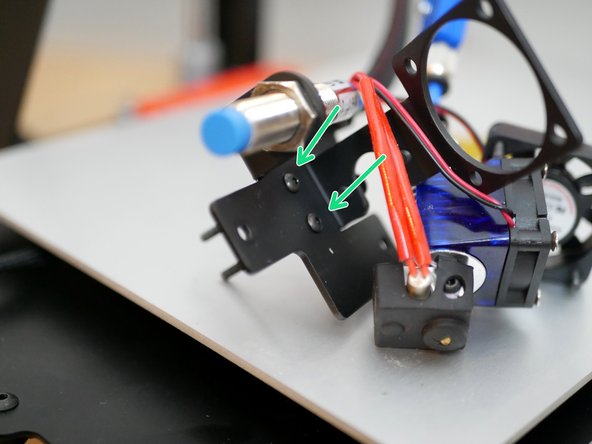

Replace the M3 x 25mm bolts on the metal tool carriage with the two M3 x 35mm bolts.

-

-

-

Mount the metal tool carriage onto the 3D printed one with three M4 x 6mm bolts.

-

-

-

Printing should be the same as before, the only thing to be aware of is that the z-height has been reduced by approx 5mm.

-

Along with the stability improvements you should also now be able to run the AXIS at higher speeds.

-

You can see it printing here.

-

Cancel: I did not complete this guide.

One other person completed this guide.

2 Comments

After assembly, I noticed the x direction had difficulty moving.

Any advice on how to finely adjust?

Not sure if it's the linear rails catching, tension in cable or motor required more torque.

Hi Nathan,

I am so sorry that I have no answer to your question but a question myself:

I have an axis, after some modifications it prints “OK”. Would you recommend the linear rails? Did you figure out the problem with the X-axis?

Ali Kara -