-

-

Check that you have all of the following:

-

3D Printed Parts (x4)

-

Rails (x4)

-

Fastener pack

-

5x8 Coupling

-

M4 Threaded Inserts (x11)

-

You will also need (not included):

-

Allen keys, Drill with metal bits (2mm/3mm), Side Cutters, Pliers, Soldering Iron (for threaded inserts)

-

-

-

Begin by disassembling the platform from the base.

-

Do this by first untying the belt from the platform.

-

Then remove the heated bed and place it to one side, you don't need to disconnect its wiring.

-

If you have the Pi Camera installed, unmount it also, again you don't need to disconnect it from the pi board.

-

Finally, remove the old HDPE linear guides holding the platform in place.

-

The platform should now be free for the next step of drilling the holes for the linear rails.

-

-

-

Next, remove the tool carriage and Y-belt from the gantry. Do not cut the belt, it will be re-used.

-

Free the y-endstop from the gantry.

-

The lead screw bracket at the top of the printer can also be removed, this part can be disregarded as it won't be re-used.

-

Disconnect the y-motor from its cable.

-

Use side cutters to break the cable ties holding the cables to the gantry.

-

Free the lead screw coupling from the z-motor shaft.

-

Finally remove the HDPE linear guides from the gantry and the entire gantry part should now be free.

-

-

-

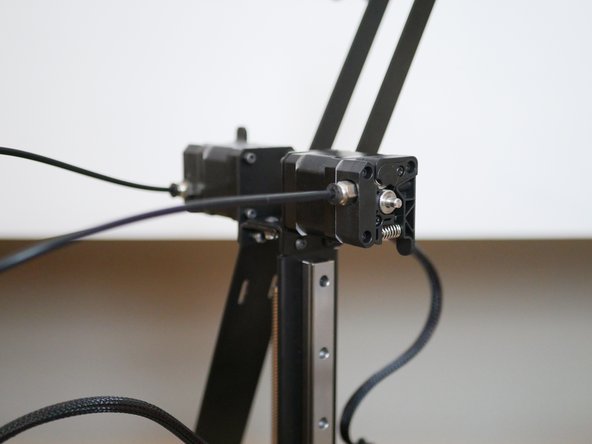

If you have an extruder installed on the vertical pillar, remove it now.

-

Next, unfasten the bolts connecting the pillar to the support bracket at the top of the pillar.

-

Remove the the motor bolts at the bottom of the pillar.

-

The pillar should now come free.

-

-

-

Use a 2mm metal drill to create 3 holes on either side of the platform.

-

Place one of the 40cm rails on the platform, 4mm +/-1mm from the edge.

-

Use a pencil to mark out where you are going to drill.

-

Secure the rail as shown with three M2 x 10mm bolts and M2 Nyloc Nuts

-

Be very careful with the carriage, either secure or remove them very carefully. If they fall off and are hit, the ball bearings inside them will escape!

-

-

-

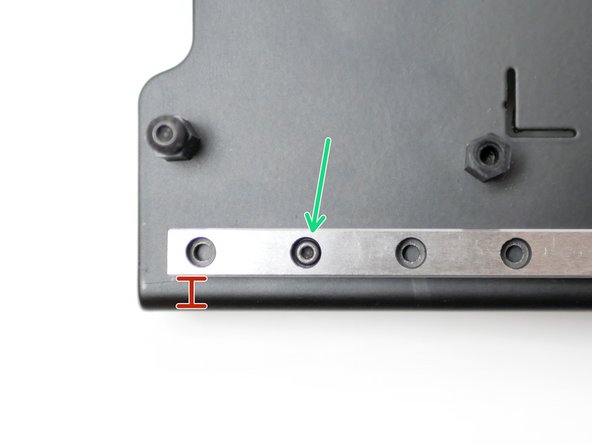

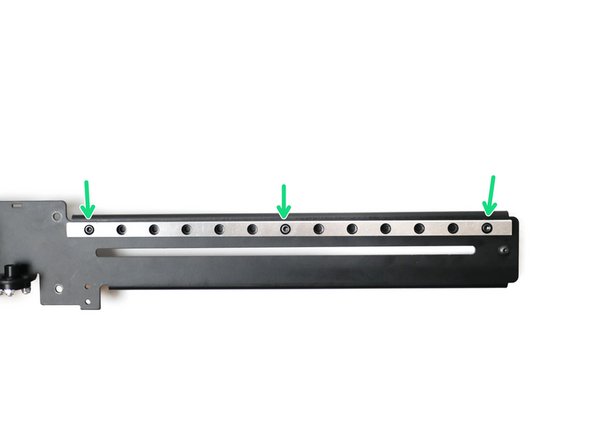

Use a 3mm bit to drill three holes into the gantry.

-

The rail should be fitted 5mm from the top edge of the gantry.

-

Secure with M3 x 12mm Cap and M3 Nyloc Nut

-

-

-

Align the thicker 15mm rail to the centre of the pillar and create marks for three holes.

-

Drill three 3mm holes into the pillar.

-

Secure the rail with three M3 x 12mm cap bolts and M3 nyloc nuts.

-

Re-install the z-pillar when done.

-

-

-

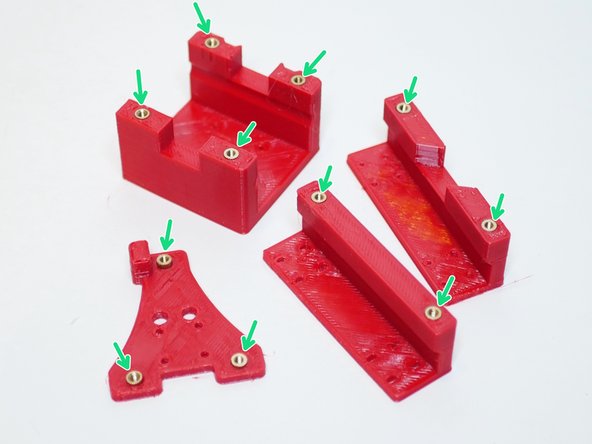

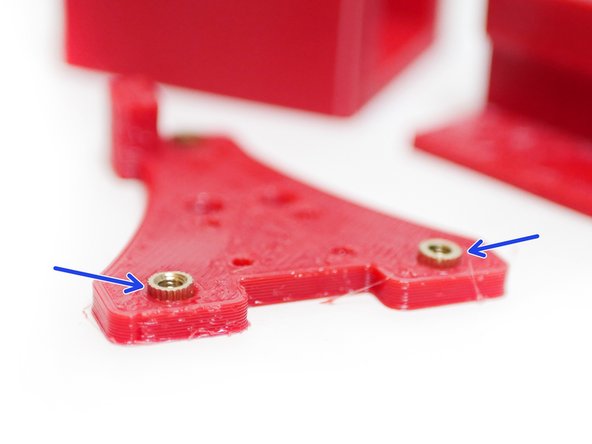

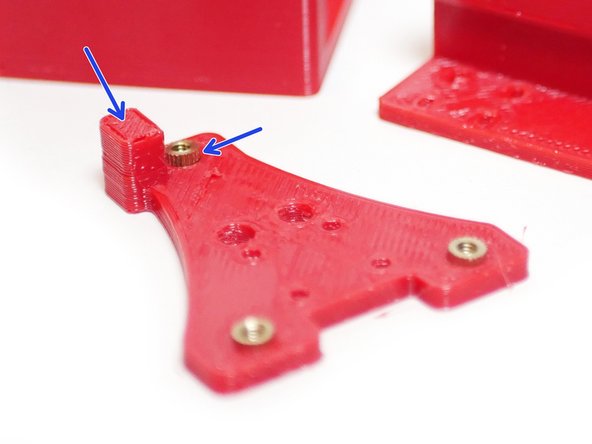

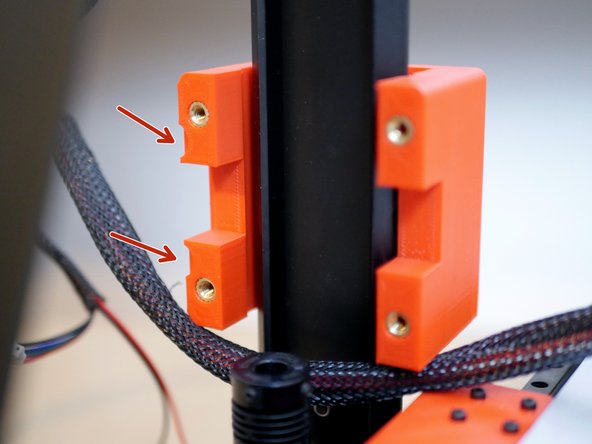

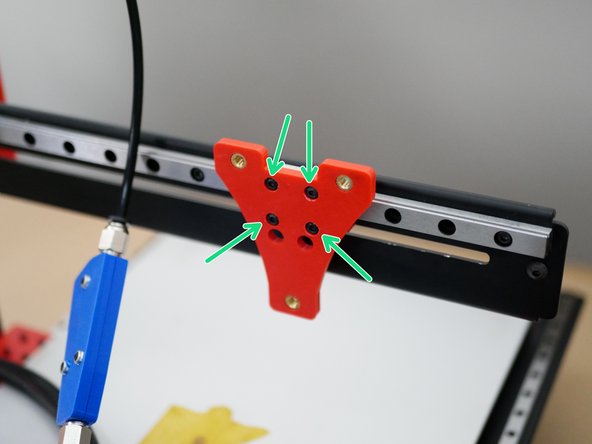

Using a soldering iron push the threaded inserts into the 3D printed parts as shown.

-

M4 Threaded Insert

-

Note that the inserts on the Tool Carriage part need to protrude out on the side shown.

-

-

-

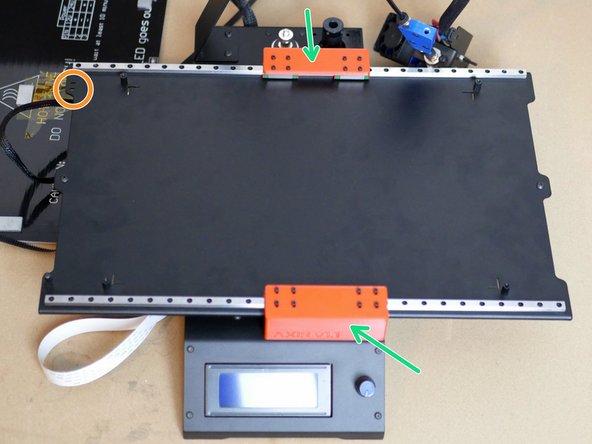

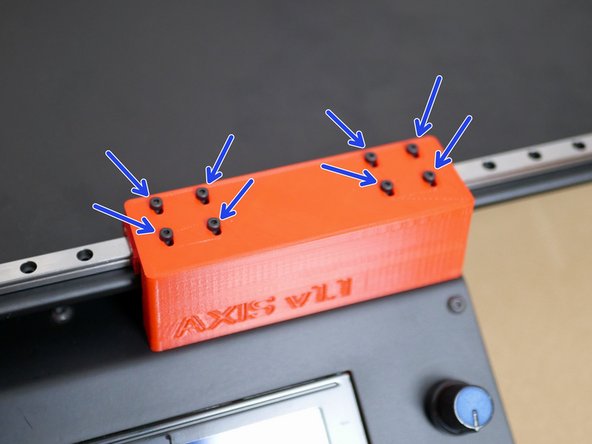

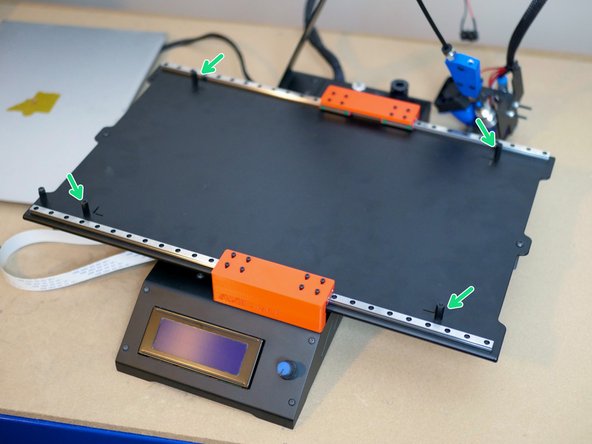

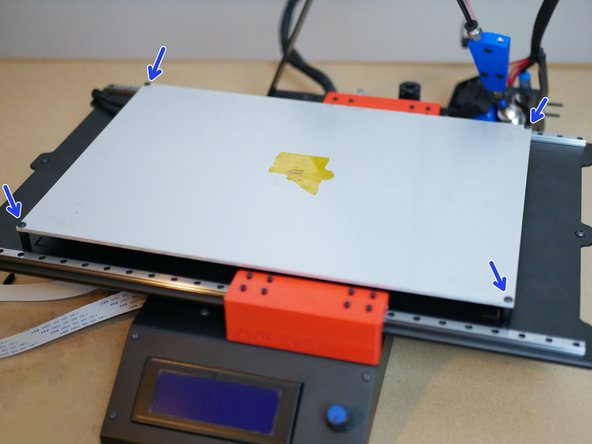

Begin by installing the two 3D printed parts to the Base with two M4 x 6mm Bolts.

-

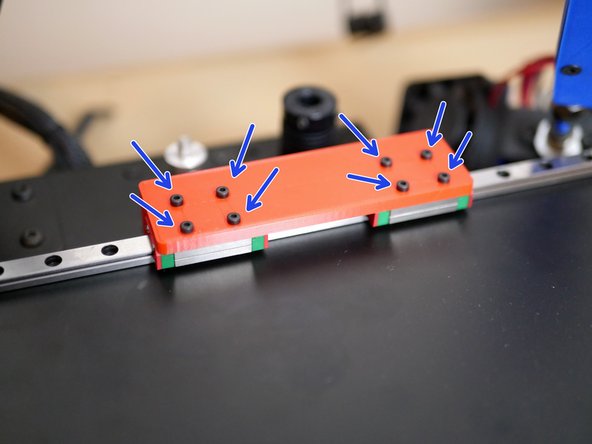

Next line up the linear rail carriages on the platform with the holes on the 3d printed brackets.

-

Secure the platform to the brackets using M2 x 6mm cap bolts.

-

Double check you have the correct orientation, the heated bed cable relief mount should be in the top left.

-

-

-

A heated bed is required for this upgrade to properly work.

-

The heated bed needs to be raised 5mm before it can be installed. To do this we replace the 10mm stand-offs with 15mm ones.

-

With the 15mm stand-offs installed, re-mount the heated bed.

-

-

-

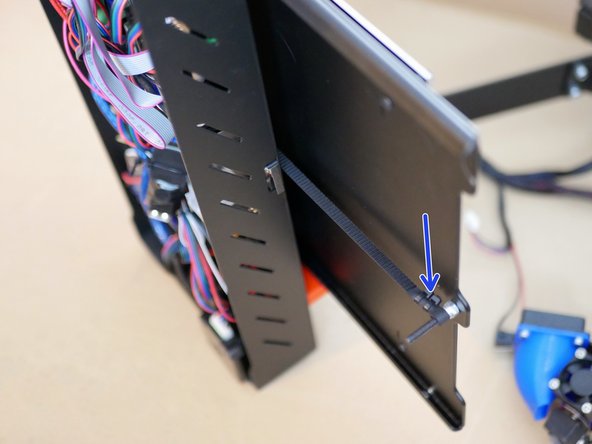

Re-install the belt by first wrapping it around the pulley on the motor and then feeding it in through the rear bracket and around the bearings.

-

You will need to use a pen to guide the belt around the bearings.

-

Secure the belt to the bolts on the ends of the platform.

-

Re-attach the Pi-cam if you have that upgrade.

-

-

-

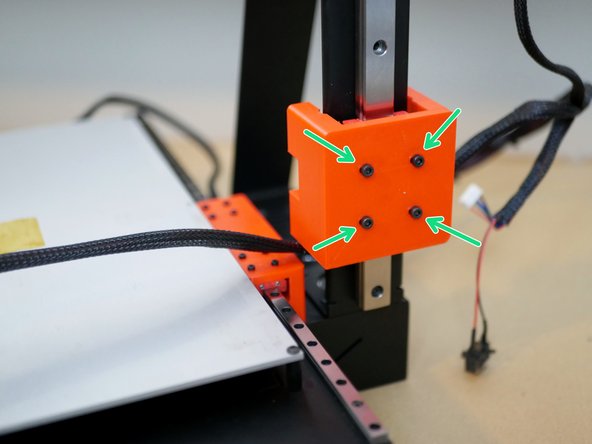

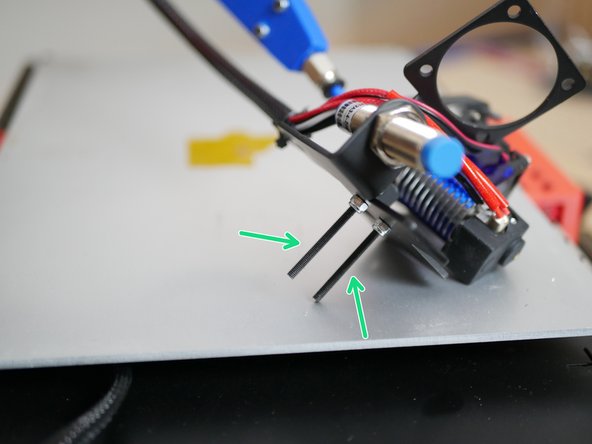

Fix the gantry carriage to the Z-Rail as shown with four M3 x 8mm cap head bolts.

-

Note the orientation of the carriage. The side with the small insets should point towards the rear of the printer.

Found the issue. The package detail list shows buttons, but actually contains caps. I was trying to find which bag had these.

Are these cap head or button head bolts? The parts bag LRU Bag 2 only has buttons in M3 x 8mm bolts.

-

-

-

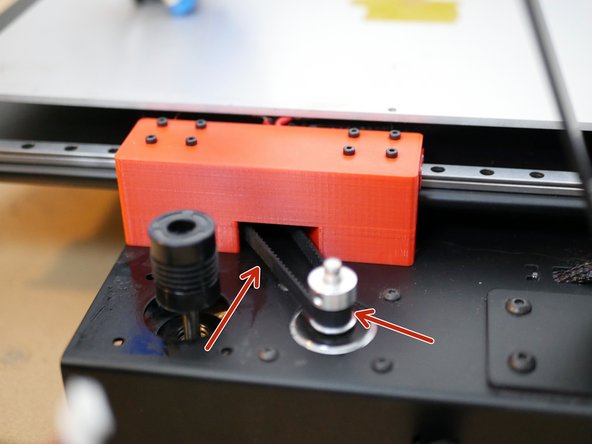

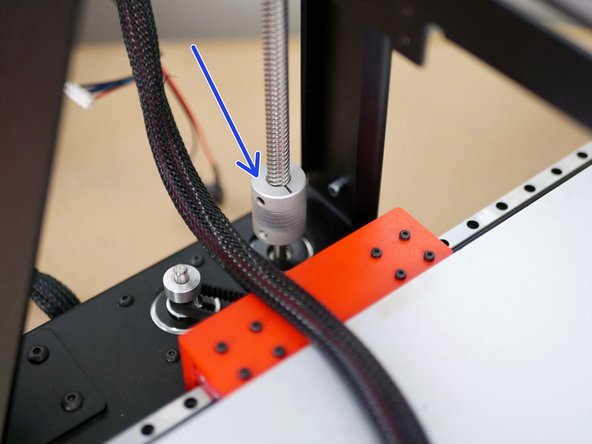

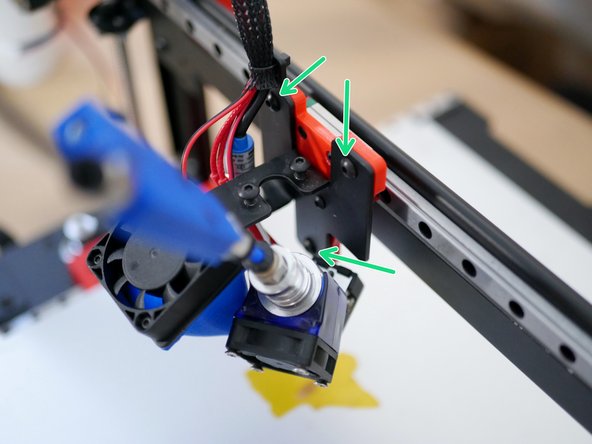

Re-attach the the lead screw to the gantry.

-

Next fix the coupling to the z-motor shaft.

-

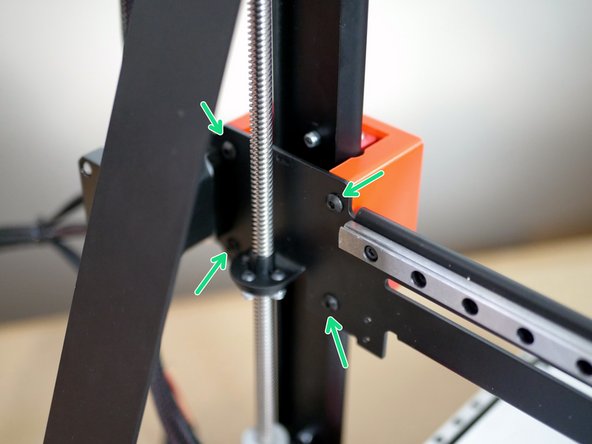

Finally, fix the gantry to the carriage with four M4 x 6mm bolts.

-

You can also now reattach the end stop and cables.

-

-

-

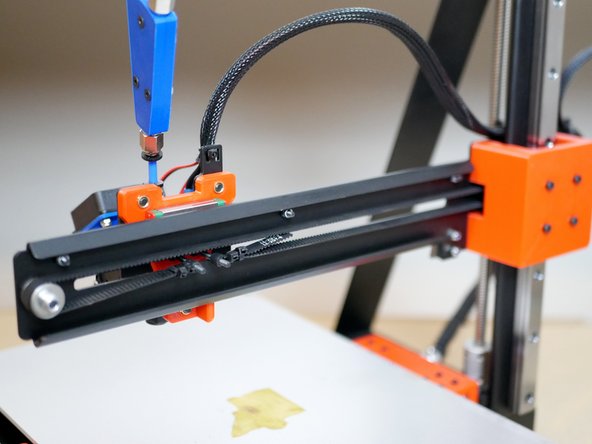

Fix the 3D printed tool carriage to the gantry rail.

-

M3 x 6mm button head

-

-

-

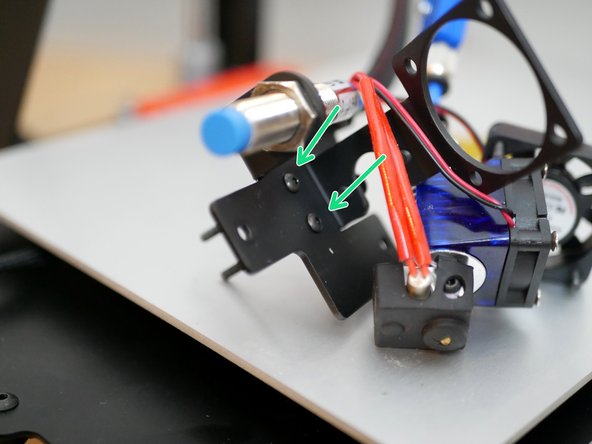

Replace the M3 x 25mm bolts on the metal tool carriage with the two M3 x 35mm bolts.

-

-

-

Mount the metal tool carriage onto the 3D printed one with three M4 x 6mm bolts.

-

-

-

Printing should be the same as before, the only thing to be aware of is that the z-height has been reduced by approx 5mm.

-

Along with the stability improvements you should also now be able to run the AXIS at higher speeds.

-

You can see it printing here.

-

Cancel: I did not complete this guide.

One other person completed this guide.

2 Comments

After assembly, I noticed the x direction had difficulty moving.

Any advice on how to finely adjust?

Not sure if it's the linear rails catching, tension in cable or motor required more torque.

Hi Nathan,

I am so sorry that I have no answer to your question but a question myself:

I have an axis, after some modifications it prints “OK”. Would you recommend the linear rails? Did you figure out the problem with the X-axis?

Ali Kara -