-

-

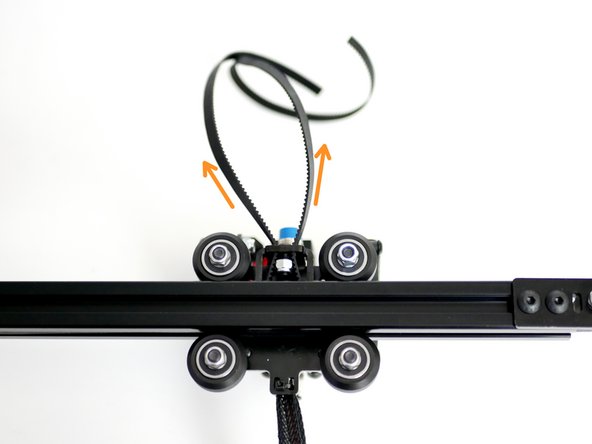

Take the remaining 1.4M of GT2 Timing Belt and feed it into the Y-Carriage as shown in the second image.

-

Make sure the loop has no turns in it and the teeth are facing inwards through out.

-

Fix an M4 x 12mm bolt with M4 nyloc nut as shown.

-

Do not tighten all the way as we'll be needing to pull the belt tight later.

-

-

-

Fasten two M5 x 8mm and M5 T-Nuts onto the Y-Idler.

-

Do not fasten all the way down.

-

Later versions of the kit do not include in this specific Idler part, instead you should use one of the extrusion brackets instead.

-

-

-

Assemble the Y-Idler:

-

M5 x 25mm Bolt

-

M5 Spacer

-

M5 15mm Washer

-

M5 Washer

-

Bearing - 685ZZ

-

Fix the Idler Assembly onto the Y-Idler bracket with an M5 Nyloc Nut - Match the orientation as in the second photo.

-

Make sure that after tightening the bearing can still spin.

The 685ZZ bearing is with the other mechanical parts in box B.

Makertech 3D - Resolved on Release Reply

Bearing - 685ZZ ??

As this part is not inside the “06 Gantry” bag it should be pointed out where it can be found and/or a photo of it NOT assembled with the other parts should be shown!

Fabian Groß - Resolved on Release Reply

-

-

-

Fix the Y-Idler assembly onto the end of the gantry beam.

-

The Y-Idler assembly should be fixed onto the same side as the endstop.

-

Make sure that the 15mm washers are pressing against the end of the beam.

-

-

-

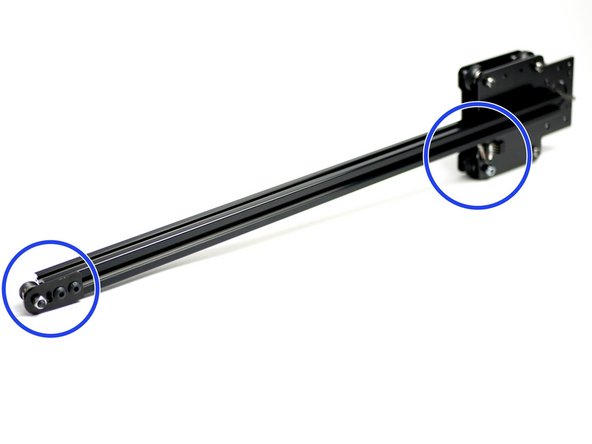

Begin by laying down the gantry and tool carriage assembly like shown in the first image.

-

Bring the rollers up to the gantry beam making sure to trap the belt loop in the grooves of the beam with teeth facing inwards.

-

-

-

Push the Tool Carriage onto the gantry beam.

-

As you slide the tool carriage onto the gantry beam the belt should loop itself around the Idler pulley bearing.

-

Make sure that the belt is tucked into the grooves between the rollers and gantry beam.

-

You may need to adjust the eccentric spacers on the carriage if it's not sliding on.

-

-

-

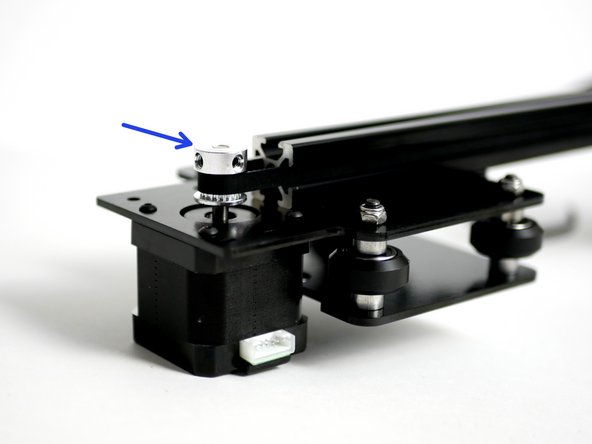

Drop onto the other side of the gantry a pulley onto the Y-Motor shaft. Match the orientation of the pulley in the image.

-

Loop the other end of the belt onto the pulley.

-

Make sure that the belt runs through the grooves of the gantry beam.

-

-

-

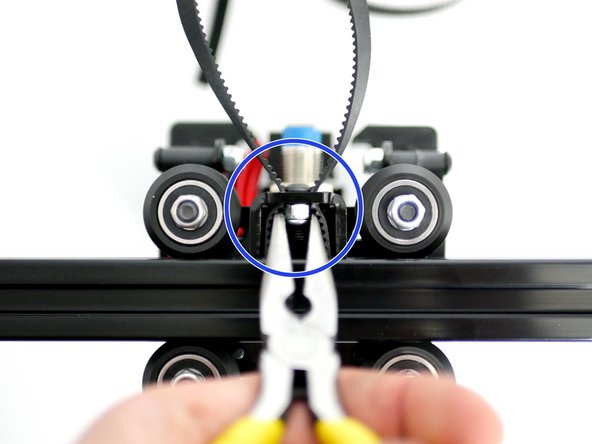

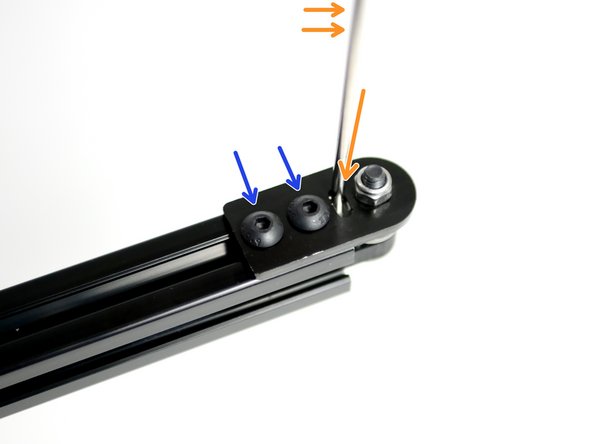

Pull the loose ends of the belt tight.

-

The teeth of the belt should catch on the bolts head holding the tension temporarily.

-

If you find it slipping way too much, tighten the M4 bolt a little more and pull the belt again, pulling the belt with the pliers will allow you to get a higher tension.

-

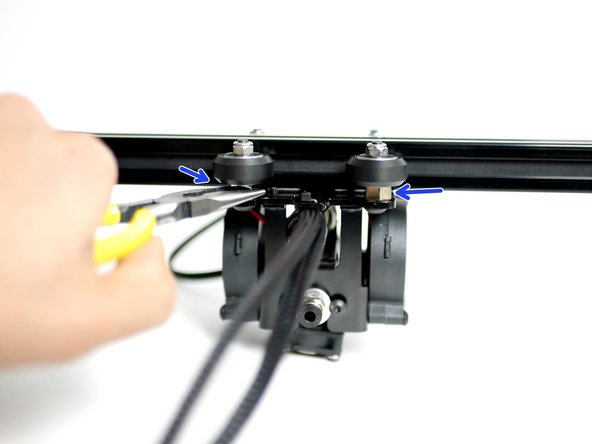

Use a pair of pliers to hold the Nyloc nut as shown in the second image and tighten down the bolt.

-

-

-

Slide the pulley up to the end of the motors shaft.

-

Secure the pulley by tightening the set screws

-

Make sure that one of the set screws is being tightened against the flat of the motor shaft.

-

-

-

Postpone this until Stage 7 Step 18 - Y-Idler install.

-

Loosen the bolts holding the the Y-Idler assmebly to the gantry beam.

-

Use a screw driver or allen key as a lever to pull the idler away from the end of the beam.

-

Hold the tension and tighten down the M5 bolts.

-

-

-

Rotate the Eccentric Spacers with a pair of pliers.

-

Tighten until there is no wobble on the Carriage.

-

-

-

Proforge 2S: Postpone this step until after Stage 7 Step 18 - Y-Idler install.

-

Proforge 2: Do this step now. Cut away the excess belt from the carriage.

Don’t cut much, leave some at least until step Stage 07 - Z - Motion + Frame

Miracle Max - Resolved on Release Reply

-

-

-

Fix an M5 x 8mm bolt with a T-Nut onto the end of the gantry beam to act a stopper for the Tool Carriage to prevent it from accidentally rolling off.

-

-

-

Push the tool carriage out up to the stopper.

-

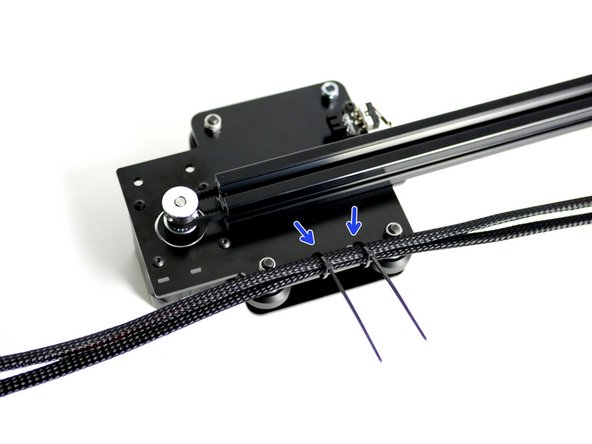

Push two cable ties into the Z-Axis Bracket holes as shown and secure the cables to it.

-

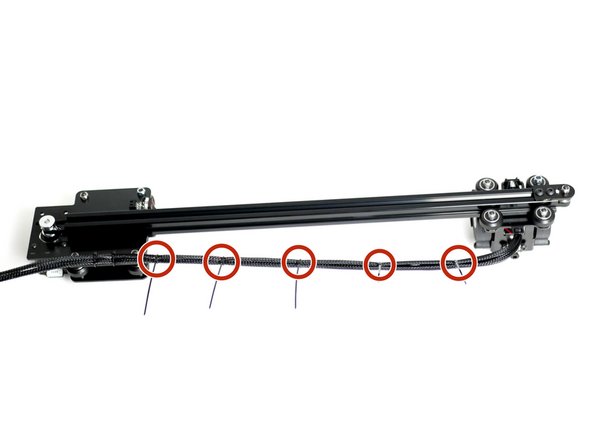

Wrap cable ties around both of the cables from the Z-Axis bracket to the tool carriage.

-

Trim away any excess form the cable ties.

For the dual switching extruder this is presumably done later, as the nozzles haven’t yet been attached?

John Gardner - Resolved on Release Reply

-

Cancel: I did not complete this guide.

22 other people completed this guide.